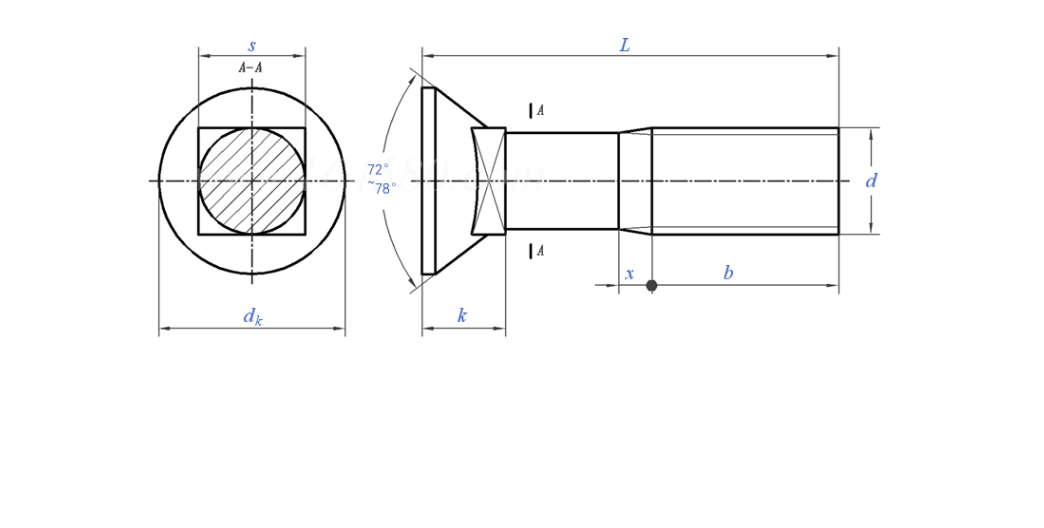

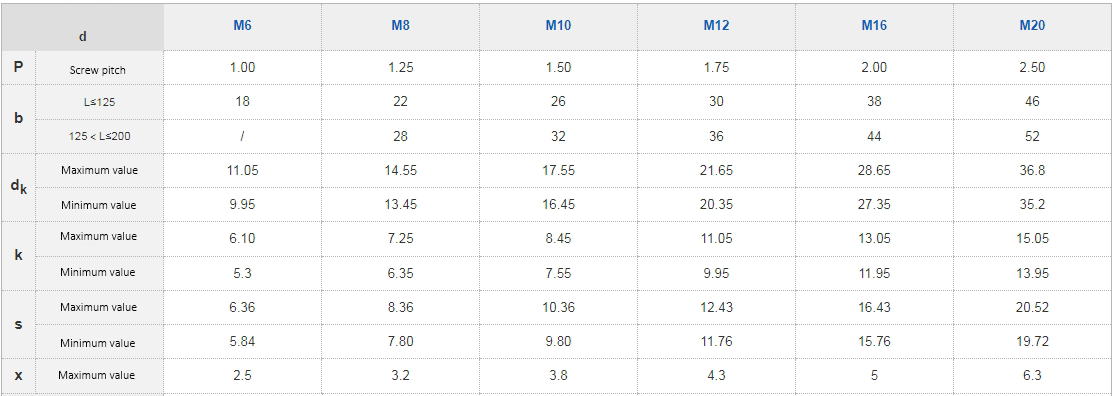

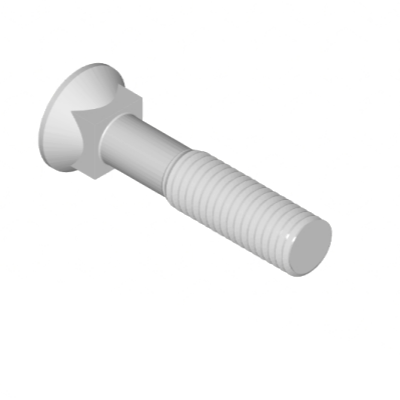

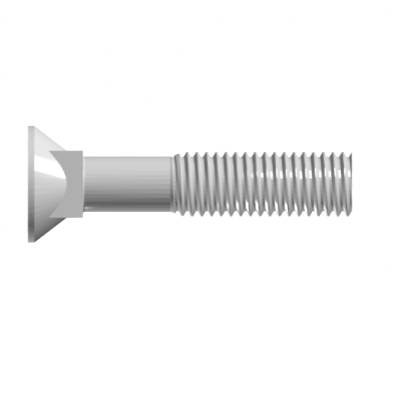

The countersunk square neck bolt is a common fastener. Its head appears square... while the threaded part is cylindrical. The characteristic of this type of bolt is that the head is relatively flat and will not protrude, so it can be used in areas that require a flat surface. At the same time, its threaded part is also relatively long, which can provide better fastening effect. The use range of countersunk square neck bolts is very wide, and they can be used in fields such as mechanical equipment, automobiles, ships, and construction. In mechanical equipment, countersunk square neck bolts are usually used to connect two or more components to ensure their position and stability. In cars and ships, they are used to connect various components such as engines, chassis, tires, etc. In the field of construction, countersunk square neck bolts are used to connect steel structures, bridges, tunnels, etc. The manufacturing materials for countersunk square neck bolts are usually carbon steel, alloy steel, stainless steel, etc. Different materials can provide different strength and corrosion resistance. When selecting countersunk square neck bolts, it is necessary to choose the appropriate material based on the specific usage environment and requirements. In addition to materials, the size of countersunk square neck bolts is also very important. The selection of dimensions should be determined based on the thickness and diameter of the connecting components. If the selected bolt size is too small, it may lead to weak connections and even loosening. If the selected size is too large, it may cause damage to the connecting components.

When using countersunk square neck bolts, the following points should be noted:

1. Ensure that the size and material of the bolts meet the requirements.

Before tightening the bolts, it is necessary to clean the surface of the connecting components to ensure the firmness of the connection.

When tightening bolts, it is necessary to use the correct torque wrench to ensure the accuracy of the torque.

4. Regularly check the tightening status of bolts to ensure the firmness of the connection.