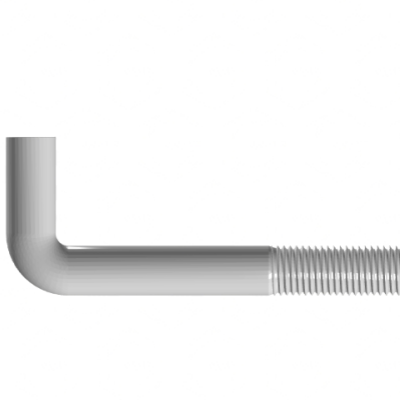

When installing mechanical components on concrete foundations, the J-shaped or L-shaped end of this bolt is buried in the concrete for use.

The tensile capacity of the anchor bolt is the tensile capacity of the round steel itself, which is equal to the cross-sectional area multiplied by the allowable stress value (Q235B: 140MPa, 16Mn or Q345:170MPA), which is the allowable tensile bearing capacity during design.

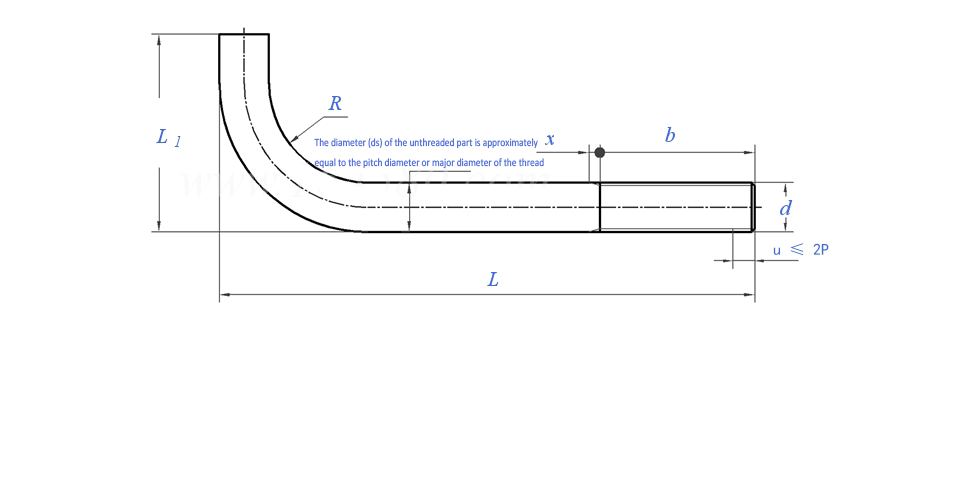

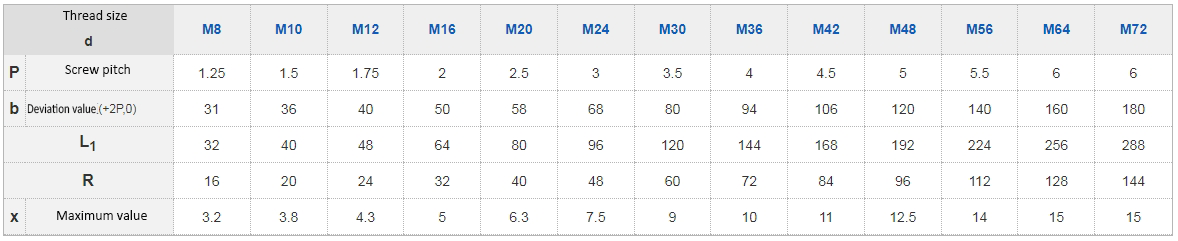

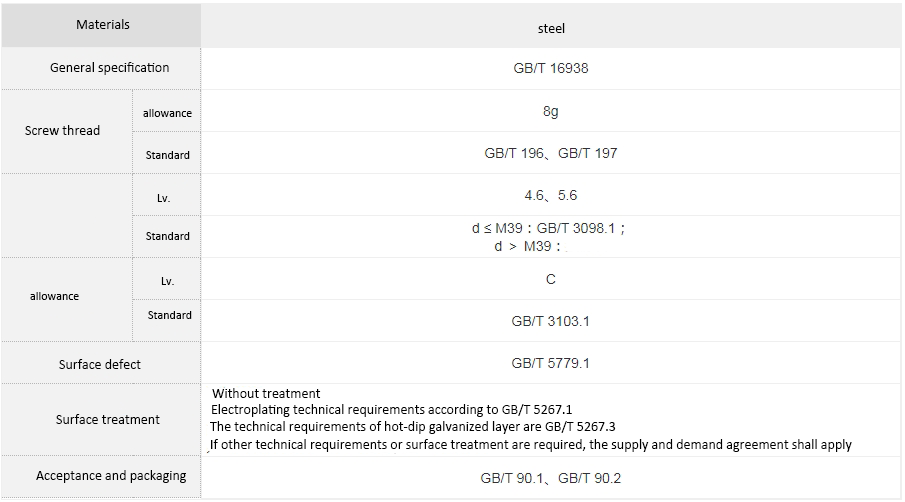

Anchor bolts are generally made of Q235 steel, which is smooth and round. Thread steel (Q345) has high strength, making the thread of the nut not as easy as smooth and round. For smooth round anchor bolts, the burial depth is generally 25 times its diameter, and then a 90 degree hook with a length of about 120mm is made. If the diameter of the bolt is large (such as 45mm) and the burial depth is too deep, a square plate can be welded at the end of the bolt to make a large head (although there are certain requirements). The burial depth and bending hook are both to ensure the friction between the bolt and the foundation, so as not to cause the bolt to be pulled out and damaged.

Anchor bolts can be divided into fixed anchor bolts, movable anchor bolts, expansion anchor anchor anchor bolts, and adhesive anchor bolts. According to different appearances, it can be divided into L-shaped embedded bolts, 9-shaped embedded bolts, U-shaped embedded bolts, welded embedded bolts, and bottom plate embedded bolts.

use to

1. Fixed anchor bolts, also known as short anchor bolts, are poured together with the foundation to fix equipment without strong vibration and impact.

2. The movable anchor bolt, also known as the long anchor bolt, is a detachable anchor bolt used to fix heavy mechanical equipment that has strong vibration and impact during operation.

3. Expansion anchor anchor bolts are often used to fix simple or auxiliary equipment that is stationary. The installation of expansion anchor anchor anchor bolts should meet the following requirements: the distance from the center of the bolt to the edge of the foundation should not be less than 7 times the diameter of the expansion anchor anchor anchor bolt; The foundation strength for installing expansion anchor anchor anchor bolts shall not be less than 10MPa; There should be no cracks at the drilling site, and attention should be paid to preventing the drill bit from colliding with the steel bars and buried pipes in the foundation; The diameter and depth of the drilling hole should match the expansion anchor anchor bolt.

4. Adhesive anchor bolts are a commonly used type of anchor bolt in recent years, and their methods and requirements are the same as those of expansion anchor anchor anchor bolts. But when bonding, pay attention to blowing out the impurities in the hole and not getting damp.

installation

1. One time embedding method: When pouring concrete, embed the anchor bolts. When the tower is controlled by overturning, the anchor bolts should be buried in one go.

2. Reserved hole method: The equipment is in place, the holes are cleaned, the anchor bolts are placed in the holes, the equipment is positioned and aligned, and then poured with non shrinkage fine stone concrete one level higher than the original foundation, and compacted. The distance from the center of the anchor bolt to the edge of the foundation should not be less than 2d (d is the diameter of the anchor bolt), and should not be less than 15mm (when d ≤ 20, it should not be less than 10mm), and should not be less than half of the width of the anchor plate plus 50mm. When the above requirements cannot be met, appropriate measures should be taken to strengthen it. The diameter of the anchor bolts used in the structure should not be less than 20mm. When subjected to seismic action, double nuts should be used for fixation or other effective measures to prevent loosening, but the anchoring length of anchor bolts should be increased by 5d compared to the anchoring length of non seismic action.

The installation plan of foundation bolts: Treatment of loosening of foundation bolts in the foundation. When tightening the foundation bolts, the bolts may be pulled out. At this time, the bolts should be adjusted to their original position first, and the foundation around the bolts should be scooped out of sufficient position. Then, two U-shaped steel bars in both vertical and horizontal directions should be welded on the bolts. Finally, the pit should be cleaned with water and grouted, The method for handling the deviation of live anchor bolts is roughly the same as that of dead anchor bolts, except that the anchor bolts can be pulled out for treatment. If the bolt is too long, it can be cut off and threaded again on the machine tool; If the bolt is too short, it can be extended by hot forging method; If the position does not match, correct it using the bending method.

Application industry: Suitable for various equipment fixation, steel structure foundation embedded parts, street lights, traffic signs, pump, boiler installation, heavy equipment embedded fixation, etc.