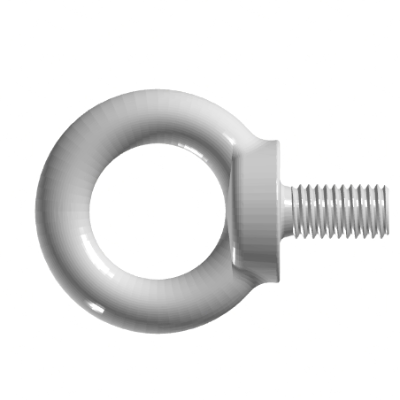

As a standard fastener, ring screws are widely used in mechanical and electrical products, and their main function is to lift loads.

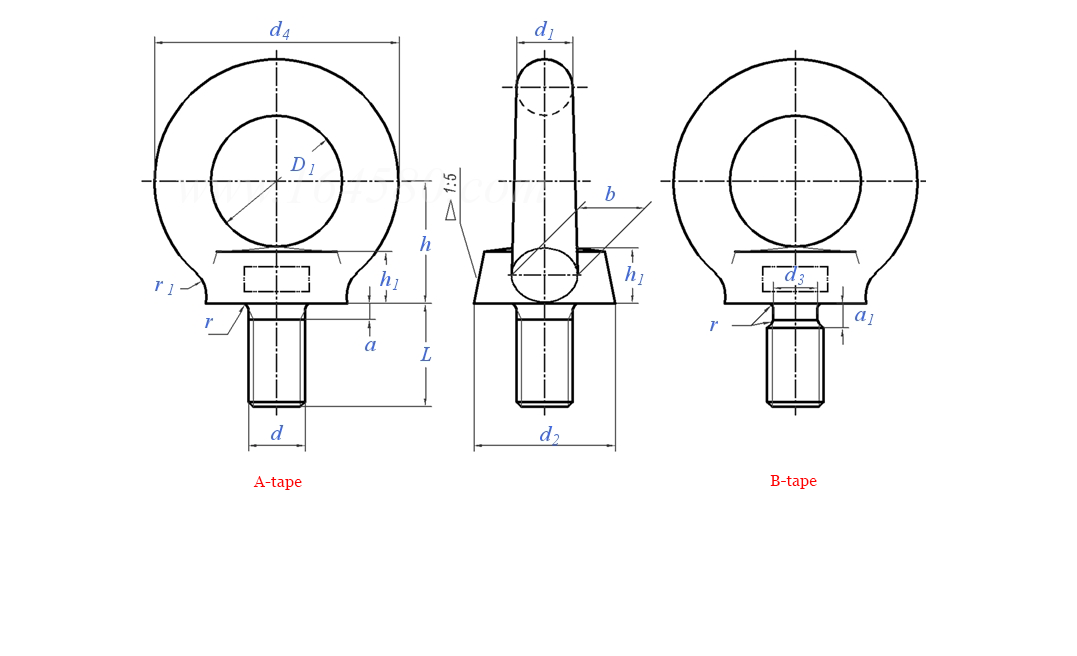

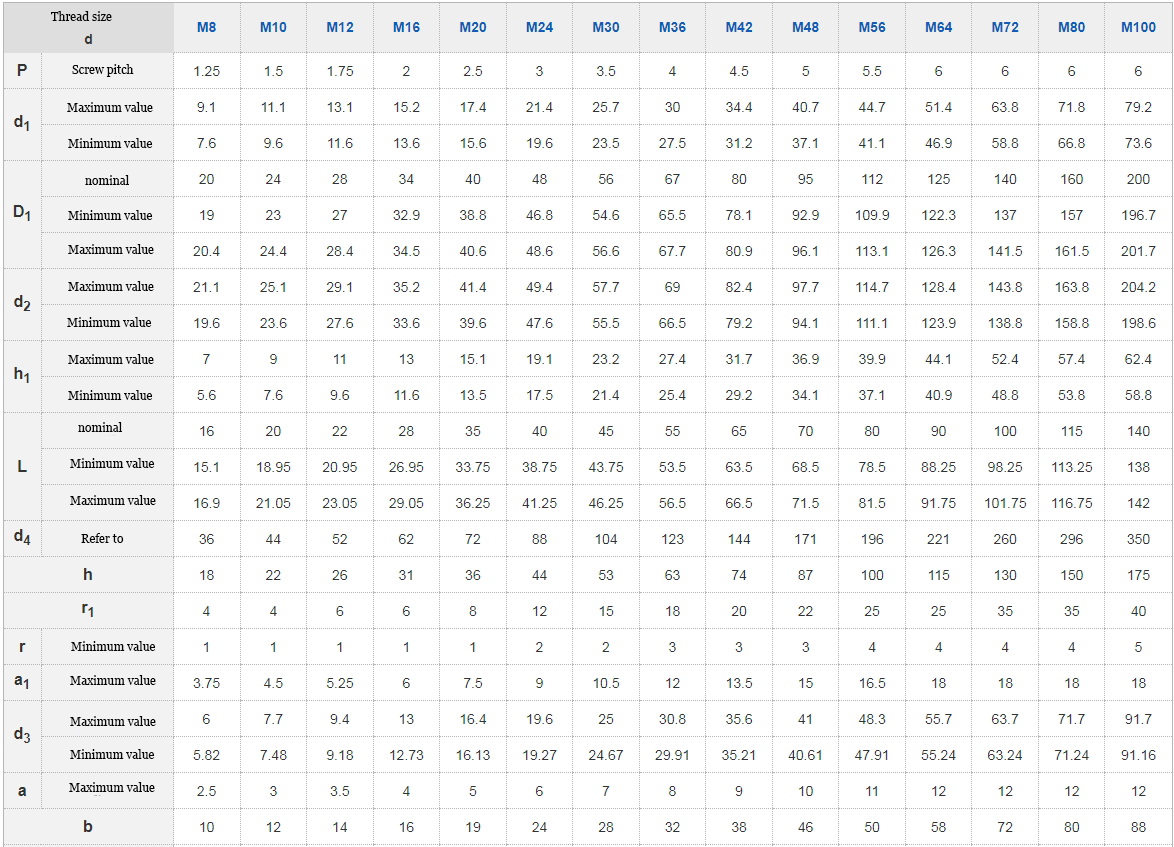

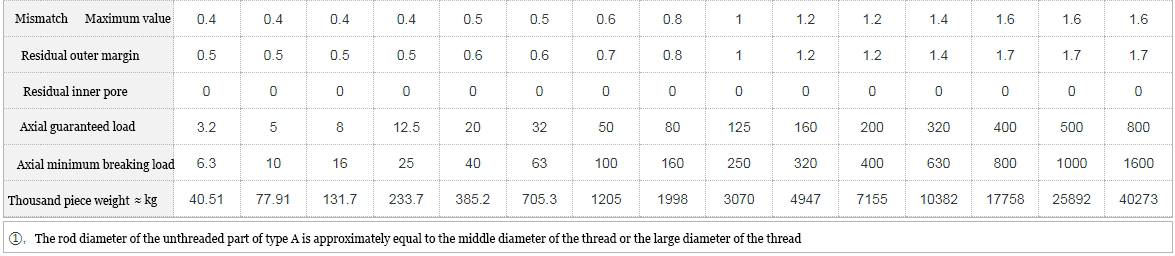

GB825-88 has detailed regulations on the structural form and size, technical requirements, lifting weight, and usage conditions of lifting eye screws. Therefore, apart from standard parts factories, other manufacturers mainly choose and use. The principle of selecting eyebolts is to ensure work safety first, and then consider factors such as connection size to achieve safety, economy, and aesthetics. To correctly select and use lifting eye screws, it is necessary to deeply analyze their stress situation, carefully study the content specified in the standard, and strive for a thorough understanding

The marking of the eyebolt shall comply with the provisions of GB1237.

Example of marking: A type eyebolt with a specification of M20, material of 20 steel, normalized treatment, and no surface treatment, marked:

Screw GB825 M20

The eyebolt must be integrally forged. Forgings should undergo normalizing treatment and remove oxide skin. The grain size of the finished product should not be lower than level 5 (GB6394), and forgings should not have overburning or crack defects.

Generally, surface treatment is not required, but according to usage requirements, surface treatments such as galvanizing, passivation, and chromium plating can be carried out, and in accordance with GB5267-85. Dehydrogenation treatment should be carried out immediately after electrogalvanizing.