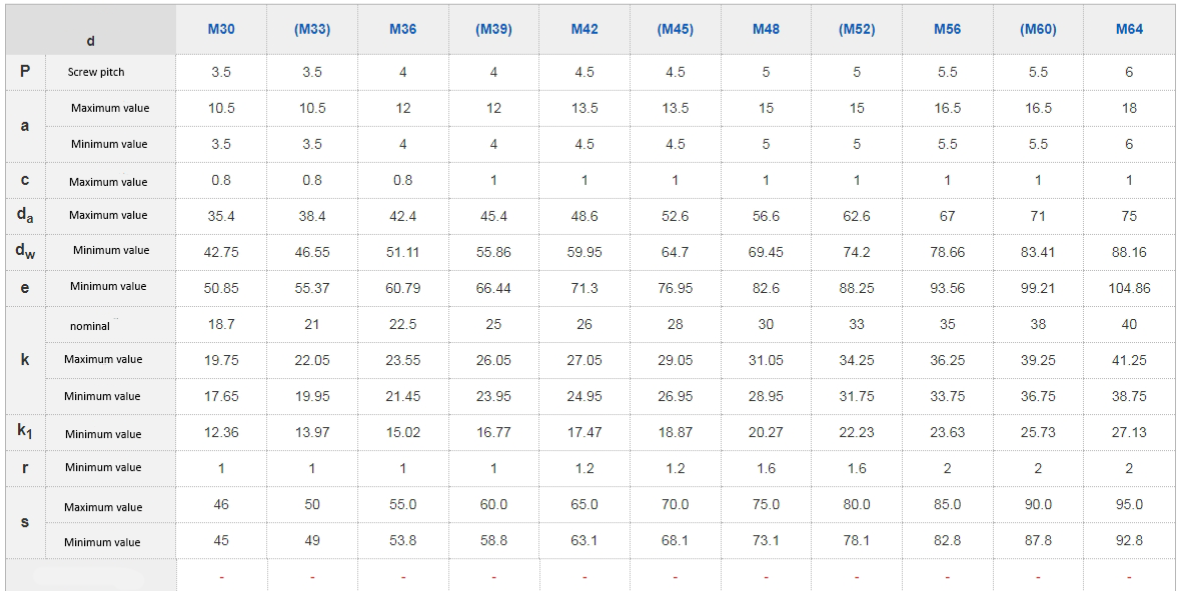

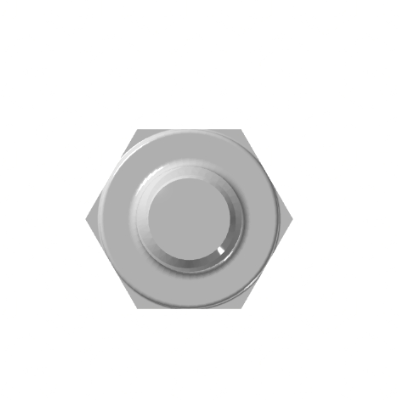

Hexagonal head bolts are divided into two types: outer hexagonal bolts and inner hexagonal screws, usually used for fastening mechanical equipment.

According to the force bearing method of the connection, there are ordinary and reamed holes. The bolts used for reaming holes should match the size of the holes and be used when subjected to lateral forces. According to the shape of the head, there are hexagonal heads, round heads, square heads, countersunk heads, etc. Generally, countersunk heads are used in places where the surface is required to be smooth and without protrusions after connection, because countersunk heads can be screwed into the parts. Round heads can also be screwed into the parts. The tightening force of square heads can be greater, But the size is very large. Hexagonal heads are the most commonly used.

In addition, in order to meet the needs of locking after installation, there are holes in the head and the rod, which can prevent the bolts from loosening when subjected to vibration.

Hexagonal head bolt material

At present, there are three main materials for hexagonal socket screws on the market: carbon steel, stainless steel, and copper.

(1) Carbon steel. We distinguish low carbon steel, medium carbon steel, high carbon steel, and alloy steel based on the carbon content in carbon steel materials.

1. Low carbon steel with C% ≤ 0.25% is commonly referred to as A3 steel in China. Basically referred to as 1008101510181022 in foreign countries. Mainly used for products without hardness requirements such as grade 4.8 bolts, grade 4 nuts, small screws, etc. (note: drill tail nails are mainly made of 1022 material).

2. Medium carbon steel 0.25% 0.45%. Currently, it is basically not used in the market.

3. Alloy steel: Adding alloy elements to plain carbon steel increases some special properties of the steel, such as 35, 40 chromium molybdenum, SCM435, and 10B38. Fangsheng screws mainly use SCM435 chromium molybdenum alloy steel, with main components including C, Si, Mn, P, S, Cr, and Mo.

(2) Stainless steel. Performance level: 45, 50, 60, 70, 80 mainly divided into austenite (18% Cr, 8% Ni) with good heat resistance, corrosion resistance, and weldability. A1, A2, A4 martensite, 13% Cr have poor corrosion resistance, high strength, and good wear resistance. C1, C2, C4 ferritic stainless steel. 18% Cr has good forging resistance and stronger corrosion resistance than martensite. At present, the main imported materials in the market are Japanese products. Mainly divided into SUS302, SUS304, and SUS316 by level.

(3) Copper. The commonly used material is brass zinc copper alloy. H62, H65, and H68 copper are mainly used as standard parts in the market. The disc elements used in carbon steel products: The material of the serial number and type can be selected. 1. Grade 4.8 hexagonal screw 1008K 1010 1015K 2. Grade 6.8 hexagonal screw.

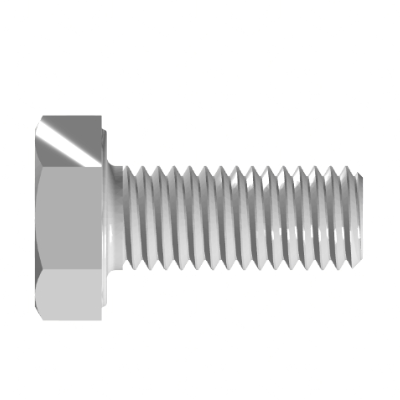

Bolt Standard

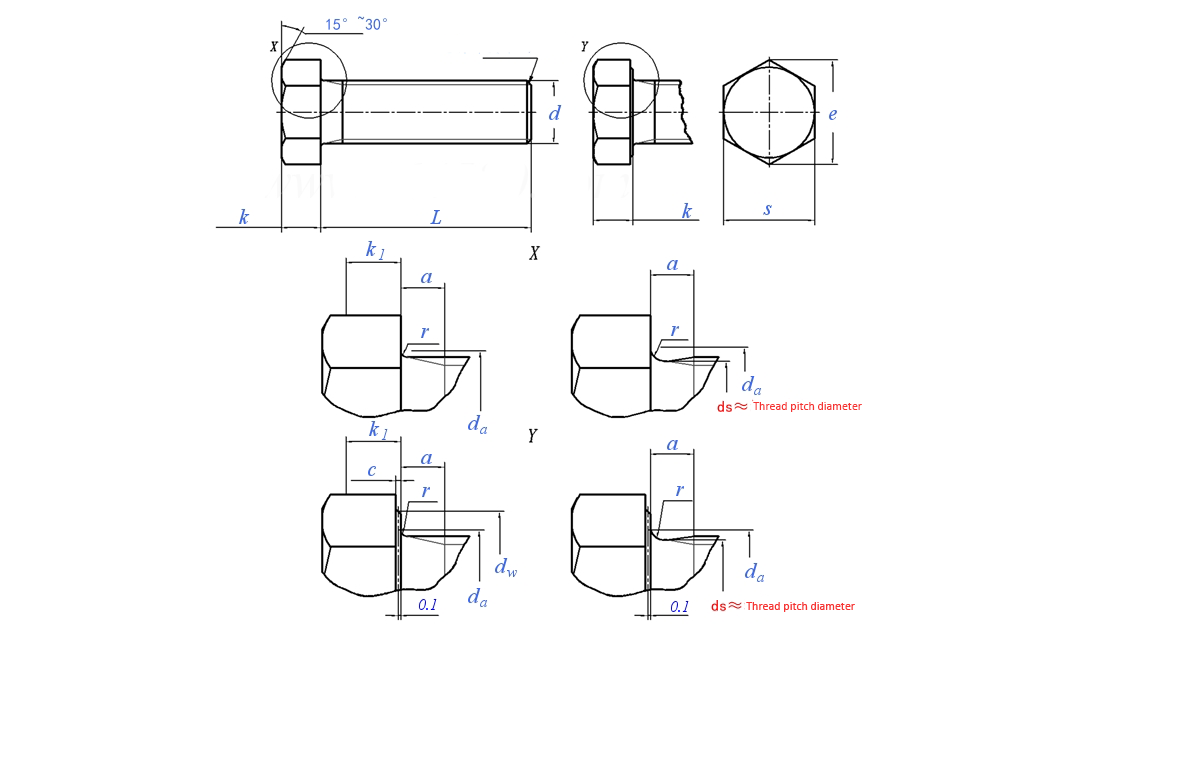

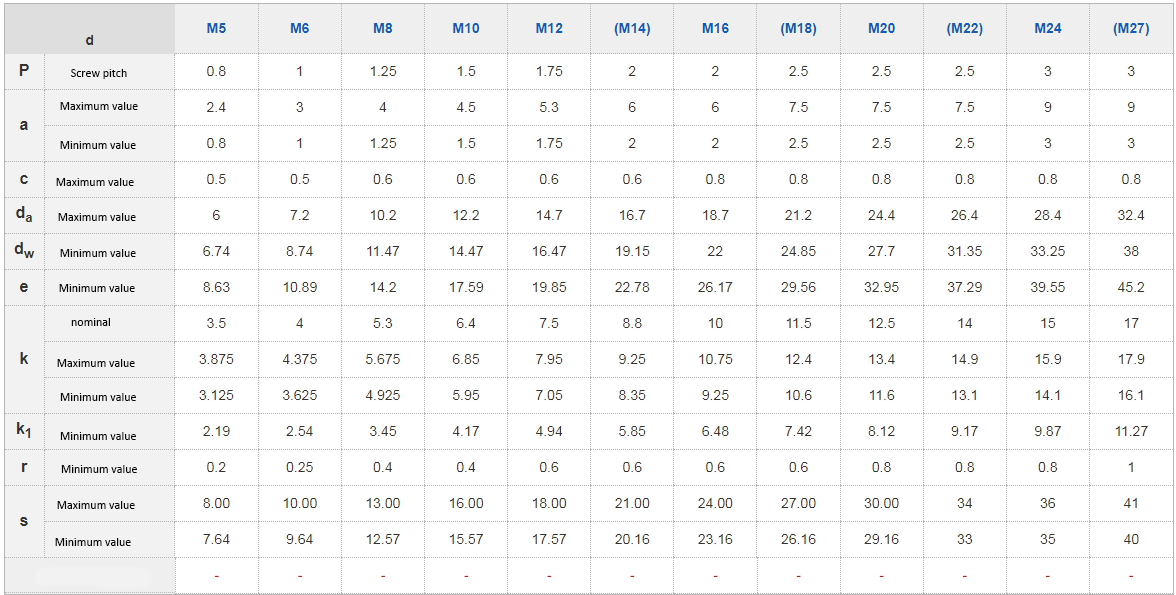

National standard for hexagon bolts GB/T5782-86

The standard specifies hexagonal head bolts with thread specifications of M3~M64, grade A and B, and grade A is used for bolts with D<=24 and L<=10D or L<=150mm (whichever is smaller); Class B is used for bolts with D>24 or L>10D or L>150 (whichever is smaller).

Dimensions of outer hexagonal bolts

External hexagonal bolt standard: DIN ANSI BS GB

Material: stainless steel or carbon steel

Diameter: 5mm~20mm, 1/4 ″~3/4 ″

Length: 8mm~200mm, 5/16 ″~8 ″

Thread: Metric, Coarse, Fine, Inch

Mechanical properties: 4.8, 5.8, 6.8, 8.8, 9.8, 10.9, 12.9

Surface treatment: natural color, galvanized, blackened, nickel plated