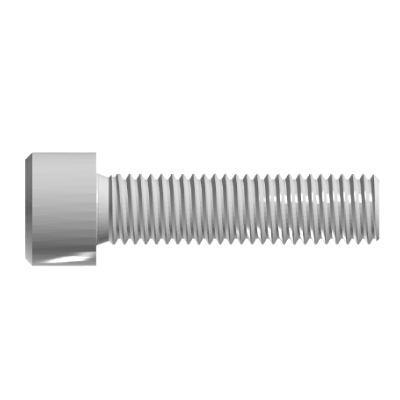

Cylindrical head socket head screws, also known as socket head bolts, cup head screws, and socket head screws, have different names but represent the same meaning. The commonly used hexagon socket head cap screws also have grades 4.8, 8.8, 10.9, and 12.9. Also known as hexagonal socket screws, also known as hexagonal socket bolts. Its head is hexagonal and also cylindrical. There are stainless steel and iron according to material. Stainless steel has stainless steel SUS202 socket head cap screws, which are made of ordinary stainless steel material. There are stainless steel SUS304 socket head cap screws and stainless steel SUS316 socket head cap screws. Iron is classified according to the strength grade of hexagon socket head screws, including 4.8 grade hexagon socket head screws, 8.8 grade hexagon socket head screws, 10.9 grade hexagon socket head screws, and 12.9 grade hexagon socket head screws. Grade 8.8-12.9 hexagonal socket head cap screws are called high-strength and high-grade hexagonal socket bolts.

hardness

Hexagon bolts are classified according to the hardness, tensile strength, yield strength, etc. of the screw wire, which is the grade of the hexagon bolt and what grade the hexagon bolt is. Different grades of hexagonal bolts are required for different product materials, and all hexagonal bolts have the following grades:

Hexagon bolts are divided into ordinary and high-strength bolts according to their strength levels. Ordinary hexagonal bolts refer to grade 4.8, while high-strength hexagonal bolts refer to grades 8.8 and above, including grades 10.9 and 12.9. Grade 12.9 hex socket bolts generally refer to black hex socket cup head screws with knurled and naturally colored oil.

The performance grades of internal hexagonal bolts used for steel structure connection are divided into more than 10 grades, including 3.6, 4.6, 4.8, 5.6, 6.8, 8.8, 9.8, 10.9, 12.9, etc. Among them, bolts of grade 8.8 and above are made of low-carbon alloy steel or medium carbon steel and heat treated (quenched and tempered), commonly referred to as high-strength bolts, and the rest are referred to as ordinary bolts. The bolt performance grade label consists of two parts of numbers, representing the nominal tensile strength value and yield strength ratio of the bolt material.

performance requirement

1. The nominal tensile strength of bolt material reaches 400MPa level;

2. The yield strength ratio of bolt material is 0.6; The nominal yield strength of bolt material reaches 400 × 0.6=240MPa level.

Performance grade 10.9 high-strength bolts, after heat treatment, can achieve:

1. The nominal tensile strength of bolt material reaches 1000MPa level;

2. The yield strength ratio of bolt material is 0.9; The nominal yield strength of bolt material reaches 1000 × 0.9=900MPa level.

The meaning of the performance grade of hexagonal socket bolts is an internationally recognized standard. Bolts with the same performance grade, regardless of their material and origin, have the same performance, and only the performance grade can be selected for design.

The grading of hexagonal bolts is basically like this, and the prices in the market will definitely vary depending on the grade. The price of high-strength hexagonal bolts is definitely much higher than that of ordinary hexagonal bolts. The four types commonly used in the market are 4.8, 8.8, 10.9, and 12.9.

The head of the hexagonal socket bolt is eccentric or skewed, which may cause serious problems. For example, from the appearance of the product, it is not aesthetically pleasing overall. Another issue is the eccentricity, which can easily cause the production tool to break easily. The most serious problem can also lead to a series of problems such as broken heads of hexagonal bolts.