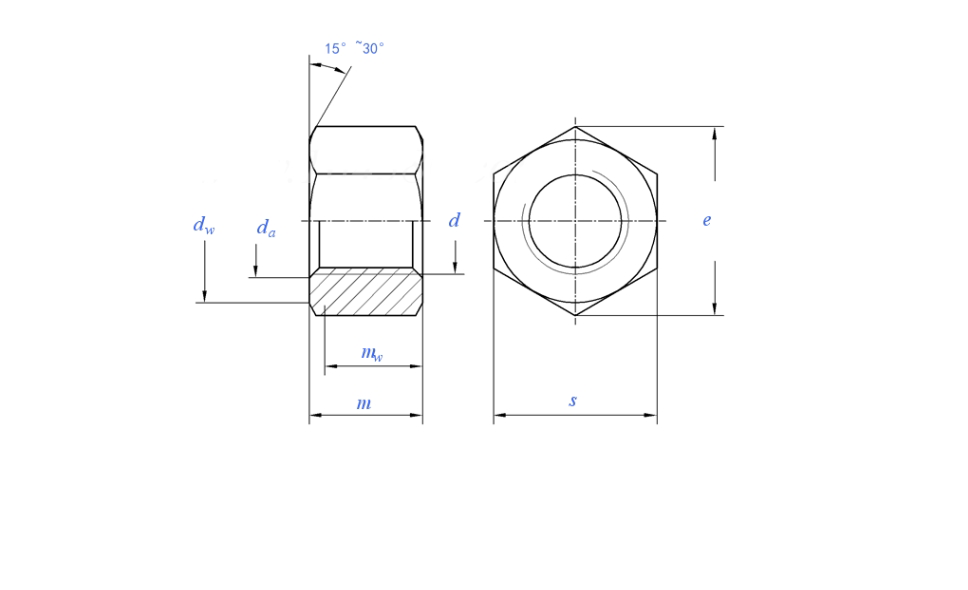

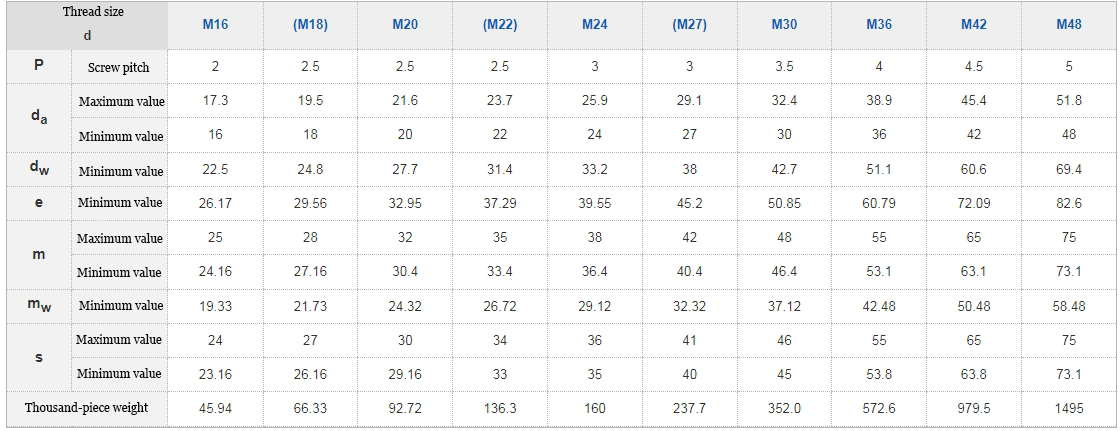

Hexagonal thickened nuts are mechanical parts that have internal threads and are used in conjunction with bolts to transmit motion or power

Hexagonal thickened nuts are components used to tighten nuts, bolts, or screws together. They are essential components for all production and manufacturing machinery. There are various types of nuts that are commonly used, including carbon steel, high-strength stainless steel, plastic steel, etc. According to product properties, they correspond to different national standard numbers

Why do thickened nuts need to be thickened so much? What is the use of thickened nuts? What are the functions of thickened nuts? When using thickened nuts, in order to prevent the bolts from falling off the fixing parts, the manufacturer will thicken the nuts according to technical requirements. Moreover, the contact area between the nuts, bolts, and threads is large, which ensures the stability of the bolt threads and prevents the bolts from slipping.

The classification of thickened nuts includes: GB55 and GB56 (extra thick nuts) according to standard numbers, high-strength thickened nuts and ordinary thickened nuts according to different materials, and electroplated thickened nuts, hot-dip galvanized thickened nuts, and Dacromet thickened nuts according to surface treatment. Thickened nuts (thickened nuts), like ordinary nuts, are used in conjunction with bolts. The difference is that the thread of thickened nuts is larger than that of ordinary nuts, and they have a larger contact area with the bolt, which can withstand greater tensile and lateral pressure than ordinary nuts. Therefore, it is commonly used in rail transit, large bridge construction, and large mechanical equipment.

How to use the special watch that wants to be securely fixed with thickened nuts? In fact, even the thickest nut has no locking effect, unless another nut is added or locked. If not, a spring washer can be added and then painted to achieve the locking effect of the thickened nut.