Anchor bolts, seemingly inconspicuous but playing a crucial role in construction projects and equipment installation, are like “unknown heroes” silently guarding their posts, providing solid support for the stability of various structures and equipment.

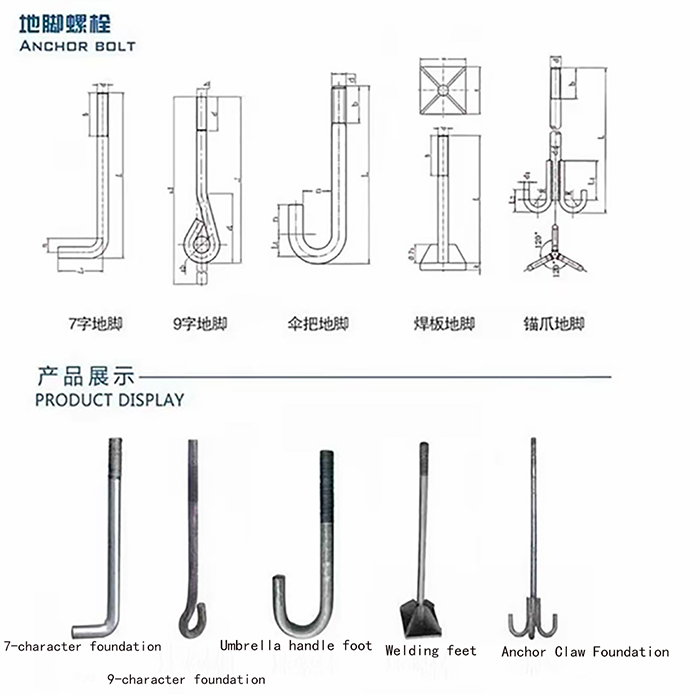

There are various types of anchor bolts to meet the needs of different application scenarios. Common ones include fixed anchor bolts, which are poured together with the foundation like a “sea fixing needle” rooted in the earth. They have excellent stability and are suitable for installation on mechanical equipment with weak vibration and impact during operation, such as some small machining machines. The activity anchor bolt is a “flexible dancer”, also known as a long anchor bolt, made of Q235 steel casting. Its significant feature is that it is easy to disassemble, making it an ideal choice for installation in heavy machinery with strong vibration and impact, such as large vibrating screens, crushers, and other equipment. Expansion anchor anchor bolts are often used to fix simple or auxiliary equipment that is stationary. When installing, it is important to note that the distance from the center of the bolt to the edge of the foundation should not be less than 7 times the diameter of the expansion anchor bolt, and the foundation strength for installing the expansion anchor bolt should not be less than 10mpa. At the same time, it is necessary to avoid cracks at the drilling site and collisions between the drill bit and the steel bars or buried pipes in the foundation. The drilling diameter and depth should also match the expansion anchor bolt. Adhesive anchor bolts are a commonly used type of anchor bolt in recent years, and their methods and requirements are similar to those of expansion anchor anchor bolts. However, when bonding, it is necessary to blow away any debris in the hole and ensure that it is not damp.

In practical applications, the construction and installation process of anchor bolts needs to be particularly rigorous. Firstly, it is necessary to ensure the verticality of the anchor bolts, which is the foundation for ensuring their load-bearing capacity and stability. During installation, there should be no tilting. Laying foundation bolts is also a key step. For the secondary grouting of dead foundation bolts, it is necessary to leave reserved holes on the foundation in advance when irrigating the foundation. When installing the equipment, the foundation bolts should be inserted, and then the foundation bolts should be irrigated with concrete or cement mortar. The tightening force of the anchor bolts should be moderate and even. If they are too loose, it may cause the connection to be unstable and the equipment to shake during operation; Tightness may cause damage or even breakage of bolts. At the same time, it is crucial to keep corresponding construction records that accurately reflect the type and specifications of the anchor bolts, providing effective technical information for future maintenance and replacement.

The quality and performance of anchor bolts are directly related to the safety and stability of the entire project or equipment. High quality anchor bolts should have sufficient strength and rigidity to withstand various forces generated during equipment operation, including tension, pressure, shear force, etc. The choice of material is also crucial, common ones such as 45 steel or 35crmo have high strength and good toughness. In addition, surface treatment of anchor bolts cannot be ignored, such as galvanizing, chrome plating, etc., which can effectively improve their corrosion resistance, extend their service life, and ensure reliable connection in various harsh environments.

The requirements for anchor bolts vary among different industries. In the field of architecture, the bearing capacity and seismic performance of anchor bolts are the primary considerations for large buildings such as skyscrapers and bridges. The installation accuracy requirements are extremely high, and even a slight deviation may affect the structural safety of the entire building. In the installation of industrial equipment, such as in the chemical and power industries, the vibration and impact of the equipment are significant. It is necessary to select appropriate types of anchor bolts and strictly follow the construction specifications for installation to ensure the normal operation and safe production of the equipment.

With the continuous advancement of technology, the design and manufacturing technology of foundation bolts are also constantly innovating. The new type of anchor bolt is more optimized in structure, such as using a special hook design to make it less prone to deformation, higher in strength, and longer in service life; In terms of materials, we have developed higher performance alloy materials to meet increasingly complex and demanding usage environments. At the same time, intelligent technology is gradually being applied to the monitoring and maintenance of foundation bolts. By using sensors to monitor the stress and status of foundation bolts in real time, potential problems can be detected in a timely manner and early warning and handling can be carried out, providing stronger guarantees for the safe operation of engineering

and equipment.

In short, although anchor bolts are just small connectors, they play an irreplaceable and important role in building and equipment installation. Only by fully understanding its types, performance, installation requirements, and application characteristics in different industries, attaching importance to its quality and technological innovation, can we better play its role and safeguard the stable and safe operation of various projects and equipment. Whether it is grand buildings or precision industrial equipment, anchor bolts silently contribute their strength and become a solid cornerstone supporting the development of modern society.

Post time: Aug-28-2024