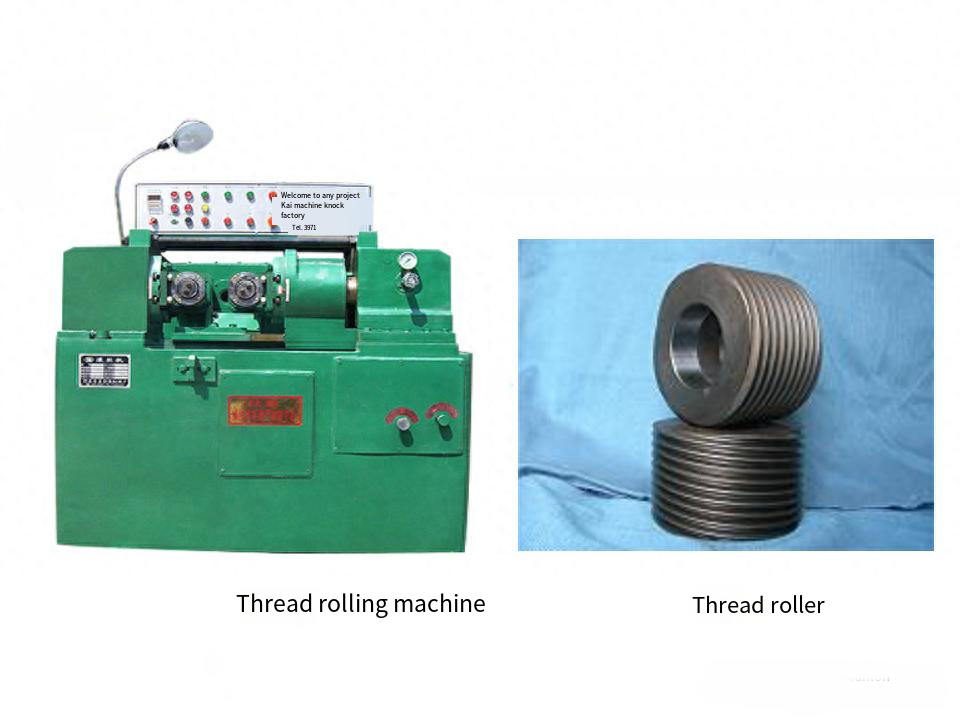

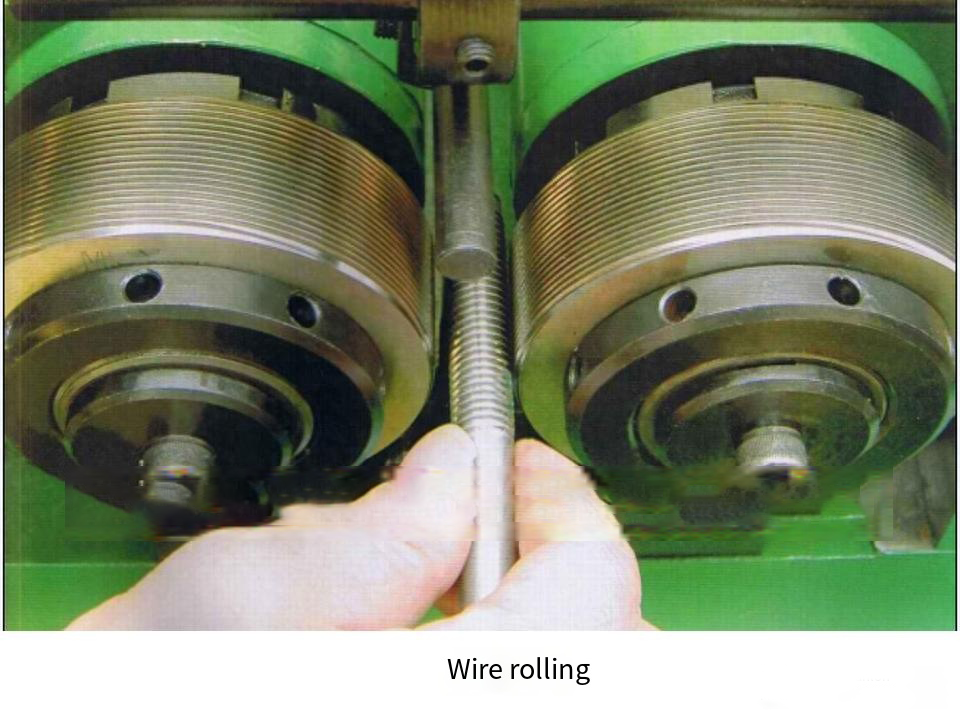

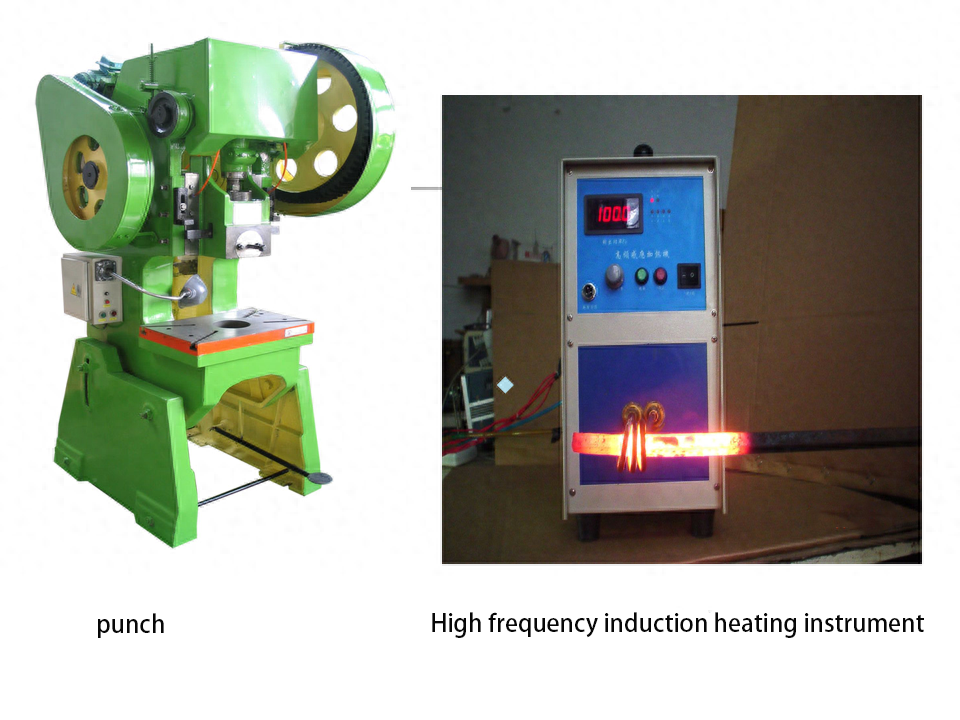

Other processBlanking, straightening (straightening), milling machine processing, drilling, milling, and so on.bolt:Small specification bolts (M16 and below) with a diameter of 1- and 8.8, such as hexagonal head boltsand hexagonal flange boltsRaw material selection: low-carbon steel (Q235, 08, 10, 18, etc.)Blank forming method: cold headingThread forming: Rolling or rolling (selection method for rolling or rolling)Process route:raw materials (selection of materials)-material modification-cold heading,one lathe processing (chamfering, flat end), one rolling or rolling wire- surface treatment(as required) – final inspection – packaging2-, 8.8 small size bolts (M16 and below)

Other processBlanking, straightening (straightening), milling machine processing, drilling, milling, and so on.bolt:Small specification bolts (M16 and below) with a diameter of 1- and 8.8, such as hexagonal head boltsand hexagonal flange boltsRaw material selection: low-carbon steel (Q235, 08, 10, 18, etc.)Blank forming method: cold headingThread forming: Rolling or rolling (selection method for rolling or rolling)Process route:raw materials (selection of materials)-material modification-cold heading,one lathe processing (chamfering, flat end), one rolling or rolling wire- surface treatment(as required) – final inspection – packaging2-, 8.8 small size bolts (M16 and below)

Raw material selection: Medium carbon steel (35,45, ML35, ML45,SWRCH35K, etc.)Blank forming method: cold headingThread forming: rolling or rolling (method of choice for rolling or rolling) Process route:Raw material (selected material) – Material modification – Cold headingturning (chamfering, flat end) a wire rolling or rolling- Heat treatment surface treatment (as required) – Final inspection – packagingSmall specification bolts of 10.9 (M16 and below)

Process route:1. Raw materials (selection of materials) -Material modification-Cold heading- Turning (chamfering, flat end) – Rolling or rolling wire- Heat treatment-Surface treatment (according to requirements, if galvanized, hydrogen removal is required) – Final inspection – Packaging

2. Raw materials (selection of materials)-Material modification-Cold heading-Turning (chamfering, flat end) – Heat treatment – Rolling or rolling wire- Surface treatment (as required, if galvanized, one final inspection and one packaging must be carried out2-, 12.9 small size bolts (M16 and below)

Raw material selection: Medium carbon alloy carbon steel (35CrMo, 42CrMo.SCM435, etc.)Blank forming method: cold headingThread forming: rolling or rolling (method of choice for rolling or rolling) Process route:1, raw materials (select materials) a material reform-cold heading a car processing (chamfering, flat end) a rolling wire or rolling wire a dephosphorization a heat treatment a detection a surface treatment (according to requirements, if galvanized to remove hydrogen) a final inspection a packaging2, raw materials (select materials) a material transformation a cold heading a car processing (chamfering flat end) a dephosphorization a heat treatment a detection- rolling wire a surface treatment (according to the requirements, if galvanized to remove hydrogen) a final inspection a packagingHex head bolt:Large specification bolts below 1-, 8.8 (M16 and above)

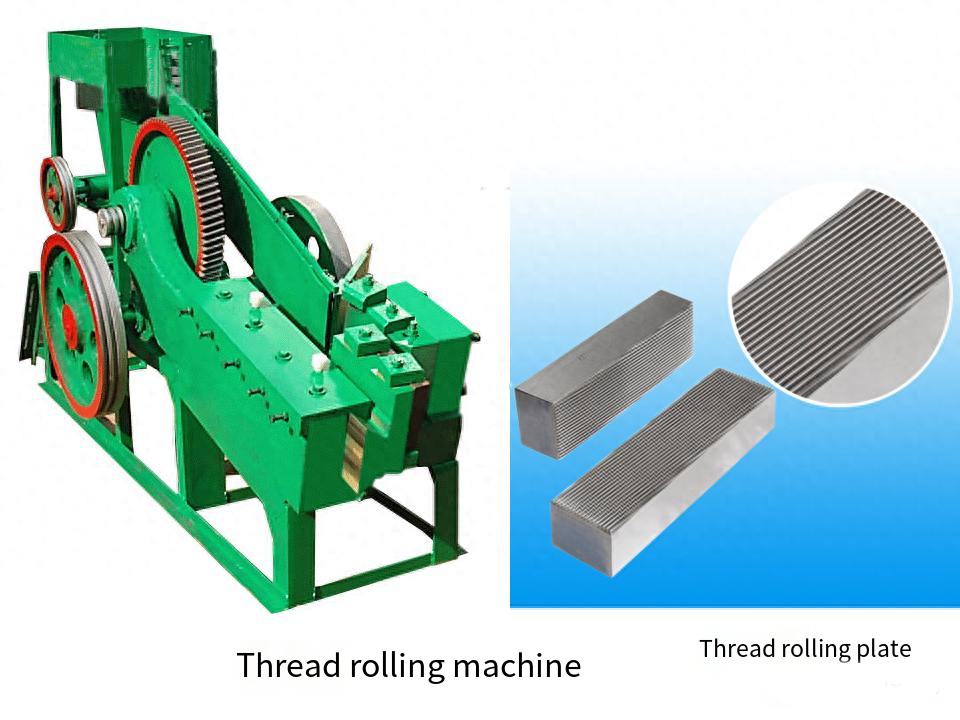

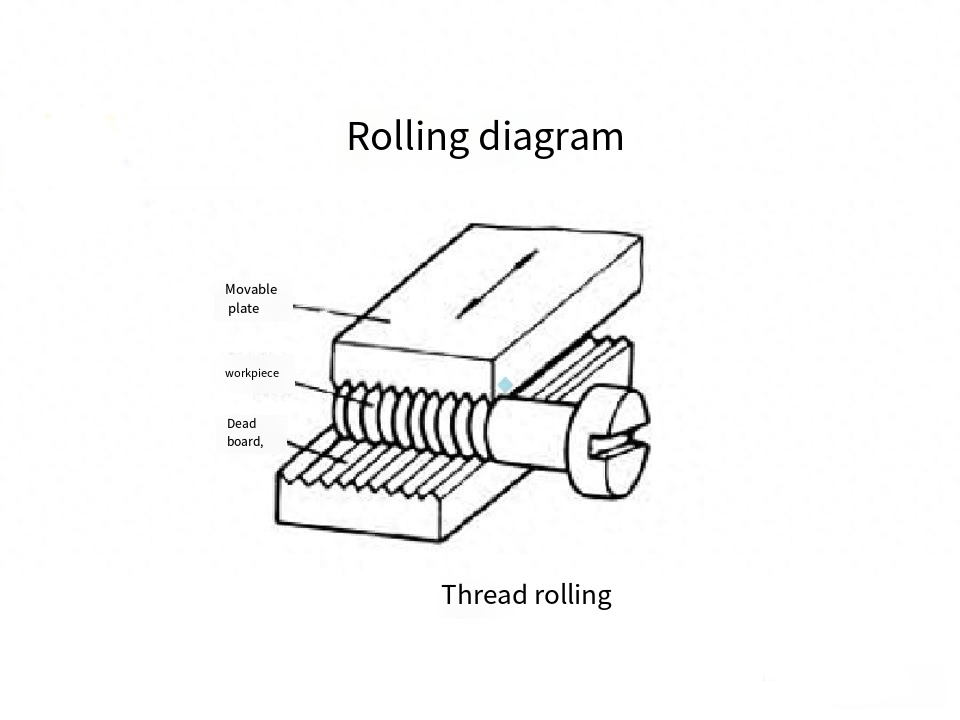

Raw material selection: Low carbon steel (Q235, thread forming: rolling process route:08, 10, 18, etc.) Blank forming method: red headingRaw materials (select materials) – Material transformation – one car processing (car screw blank) Red heading one car processing (car head, chamfer, flat end length, etc.) One (marking) one grinding (grinding screw blank) – rolling wire surface treatment (as required) One final inspection – packaging2-, 8.8 large size bolts (M16 and above)

Raw material selection: medium carbon steel (35, 45, ML35, ML45, SWRCH35K, etc.) Blank forming method: red heading thread forming: rolling wire

Process route:

1, raw materials (select materials) a material transformation- a car processing (car screw blank) a red heading a car processing (car head, chamfer, flat end flat length, etc.) a (marking) a heat treatment (shot blasting) a grinding (grinding screw blank) a rolling wire – surface treatment (as required) – final inspection – packaging

2, raw materials (select materials) a material transformation a car processing (car screw billet) a red heading a car processing (car head, chamfer, flat end flat length, etc.) a (marking) a (shot blasting) a grinding (grinding screw billet) a rolling wire a heat treatment and treatment (as required) a final inspection a packagingLarge size bolts of 2-, 10.9 (M16 and below)

Raw material selection: Medium carbon alloy carbon steel (40Cr, Scr440, 35CrMo, etc.) Blank forming method: red heading thread forming: rolling process route:

1, raw materials (select materials) a material transformation a car processing (car screw billet) a red heading a car processing (car head, chamfering, flat end flat length, etc.) a (marking) a heat treatment a (shot blasting) a grinding (grinding screw billet) a rolling wire a surface treatment (according to requirements, if galvanized to remove hydrogen) a final inspection – packaging

2, raw materials (select materials) a material transformation a car processing (car screw billet) a red heading a car processing (car head, chamfering, flat end flat length, etc.) a (marking) a (shot blasting) a grinding (grinding screw billet) a rolling wire – heat treatment – surface treatment (according to requirements, if galvanized to remove hydrogen) a final inspection – packagingLarge size bolts of 2-, 12.9 (M16 and above)

Raw material selection: Medium carbon alloy carbon steel (35CrMo, 42CrMo, SCM435, etc.)Blank forming method: red upsettingThread forming:Rolling process:

1, raw materials (select materials) a material transformation a car processing (car screw billet) a red heading a car processing (car head, chamfering, flat end flat length, etc.) a (marking) a dephosphorization a heat treatment a detection (shot blasting) a grinding (grinding screw billet) a rolling wire a surface treatment (according to requirements, if galvanized to remove hydrogen) a final inspection – packaging

2, raw materials (select materials) a material transformation a car processing (car screw billet) a red heading a car processing (car head, chamfering, flat end flat length, etc.) a (marking) a (shot blasting) a grinding (grinding screw billet) a rolling wire a dephosphorization a heat treatment a surface treatment (according to requirements, if galvanized to remove hydrogen) a final inspection of a packaging

Post time: Oct-06-2023