Division of responsibilities for fastener torque

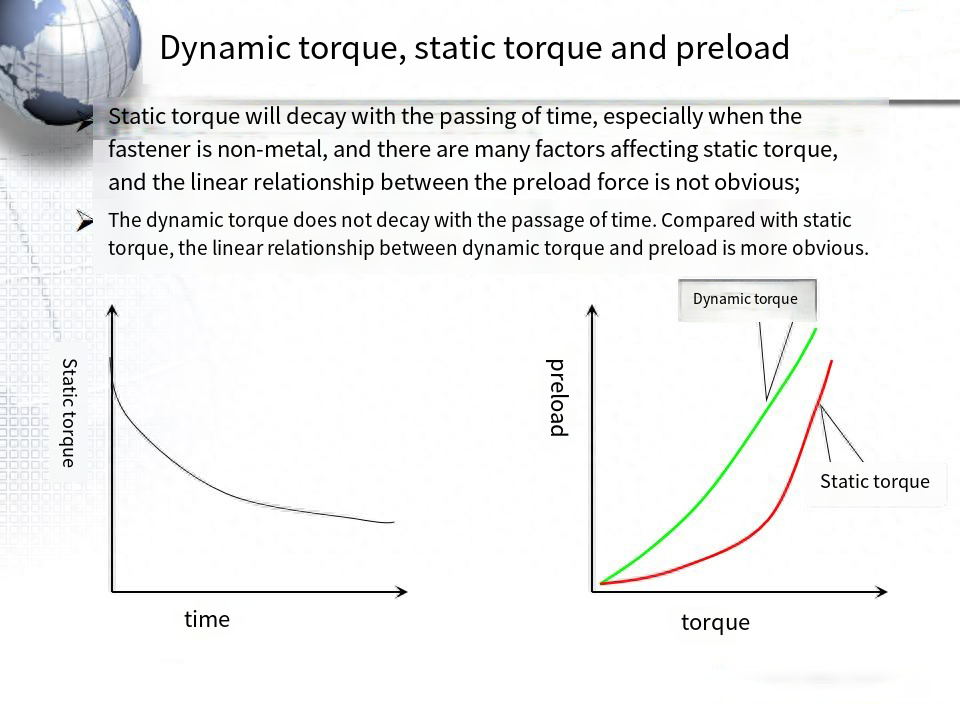

1. PATAC is responsible for releasing dynamic torque and initial static torque. PATAC releases dynamic torque standard according to design requirements, combined with experimental results and road test results.

2. ME is responsible for releasing static torqueAccording to the dynamic torque released by PATAC, the torque of the fastening tool is adjusted in Nominal value of the dynamic torque standard on the production line. Then the static torque is measured according to the normal production mode. Using the statistical method (30 sets of data), the Nominal and tolerance of the static torque standard are obtained, and the static torque standard is obtained.

Dynamic torque and static torque writing format

1. Dynamic torque

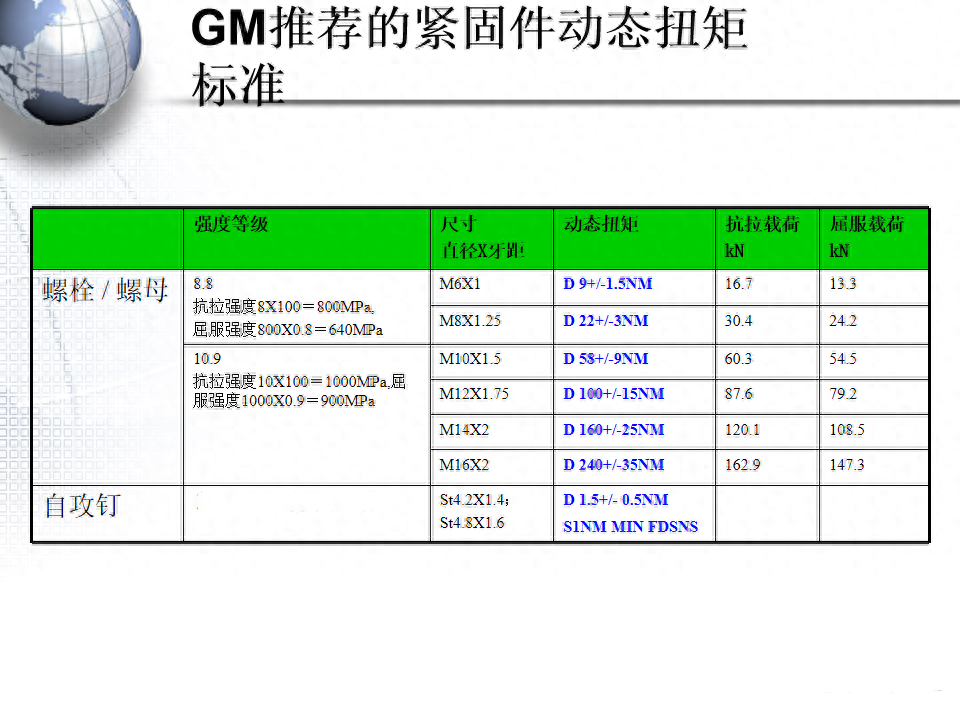

D nominal+/-tolerance NM ; Dynamic torque is written in the form of nominal +/tolerances such as D30+/-5nm; There is no space between D and 30+/-5NM;Where D stands for Dynamic; NM is the unit of torque: Newton. Meters; tolerance should be symmetrical tolerance and should not be set to the form of asymmetric tolerance up and down. For example, D30+3/-5NM is not correct.In the production, the dynamic torque value of the fastening tool should be nominal, and should not be deviated from the nominal value intentionally;

2. Static torque

SA-BNM; The static moment should be written as a range of forms such as: S25-35NM; No space between S and 25-30NM; Where S stands for Static; A represents the lower limit of static torque, B represents the upper limit of static torque; NM is the unit of torque: Newton. Meters;

Dynamic torque and static torque writing format

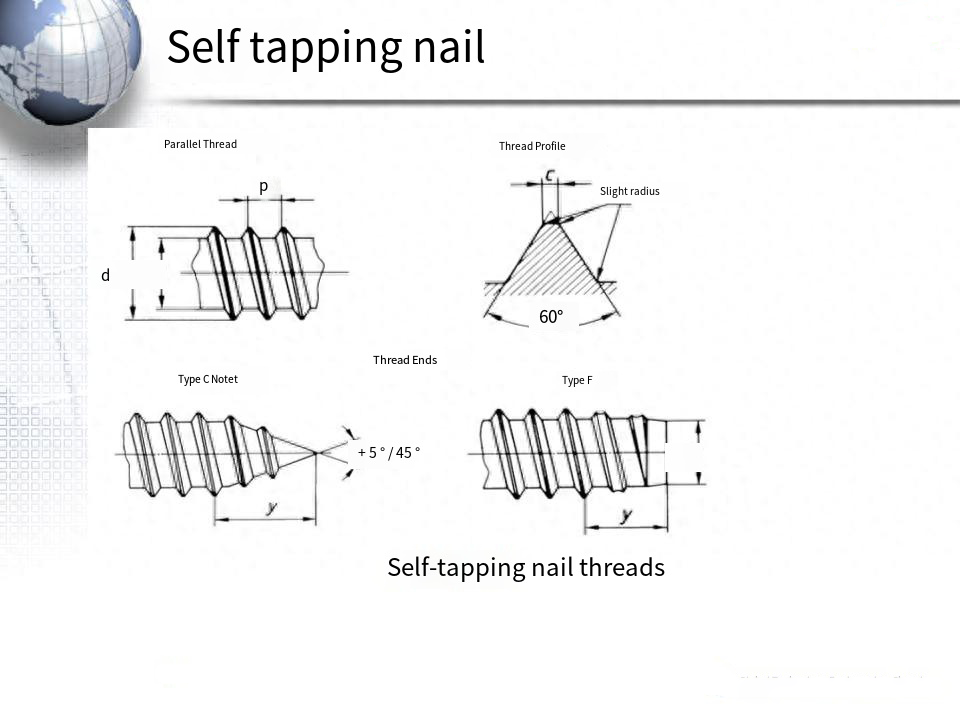

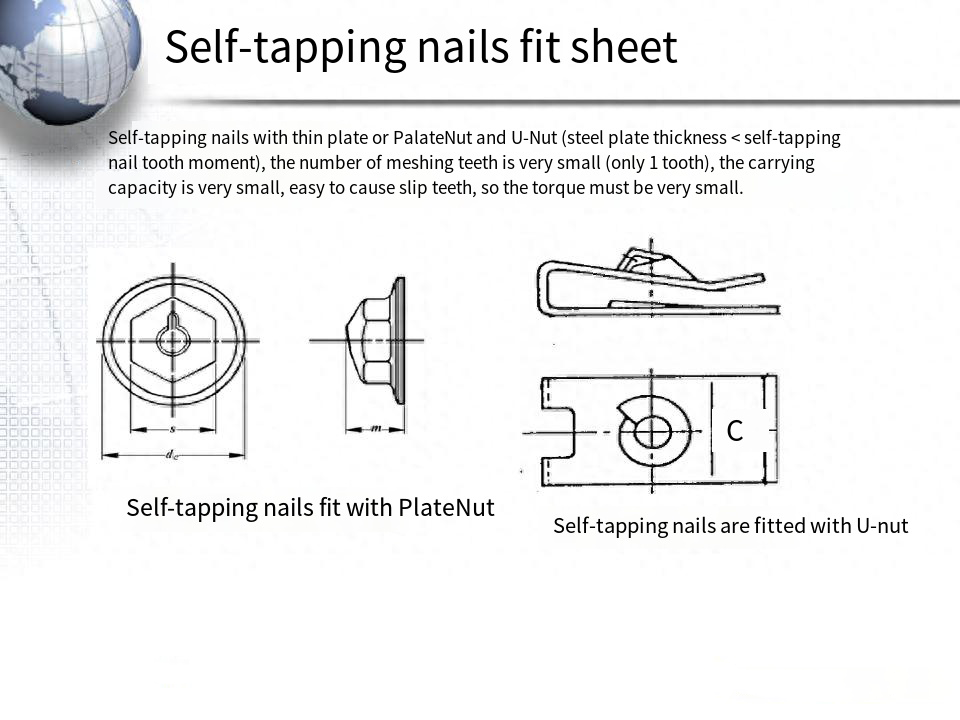

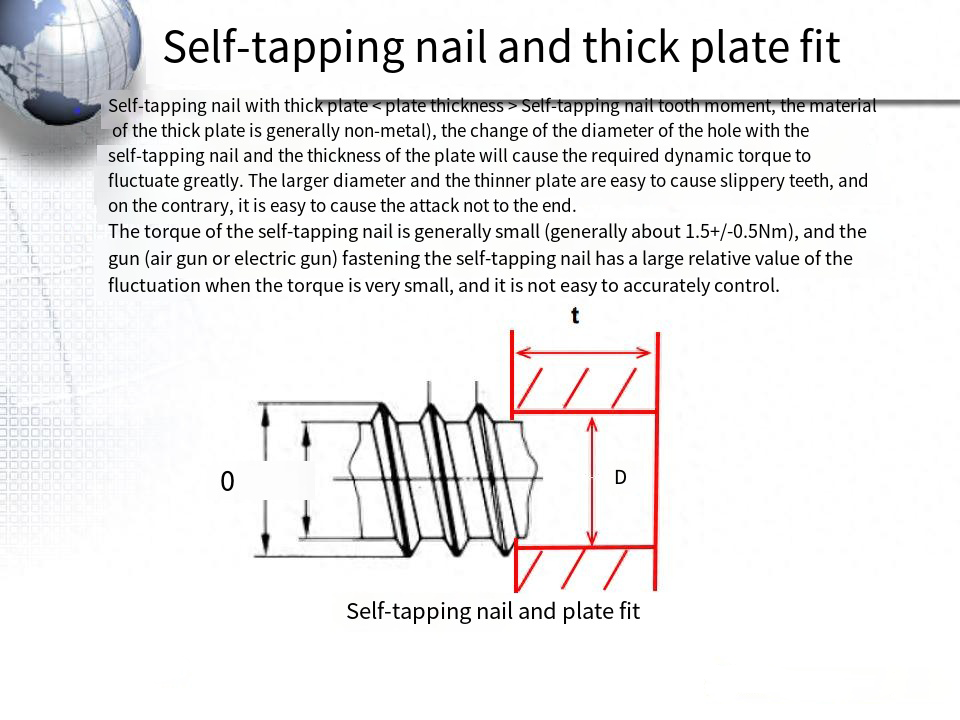

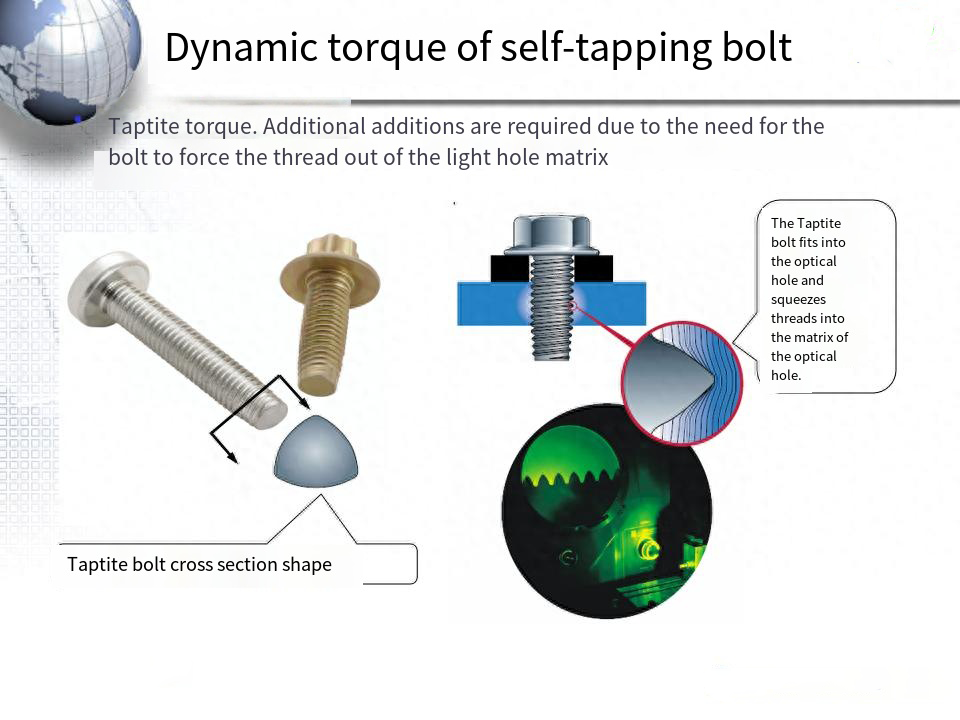

3. Dynamic torque of self-seated nails Self-seated nails are usually seated under the FDSNS standard (Fully DrivenSeated Not Stripped).For example: D1.5+/-0.5NM S1NM MIN FDSNSWhere D stands for Dynamic(dynamic); Followed by a space;1.5+/-0.5NM indicates the range of dynamic torque, 1.5NM is only for a reference of the actual set torque in production, and is not expressed as Nominal value. The actual dynamic torque used is adjusted by the production according to the actual situation of the gun dynamic torque, but it must be ensured that the FDSNS standard (Fully Driven SeatedNot Stripped, that is, the tooth is not slipped).Finally, note FDSNS (Fully Driven NotStripped).

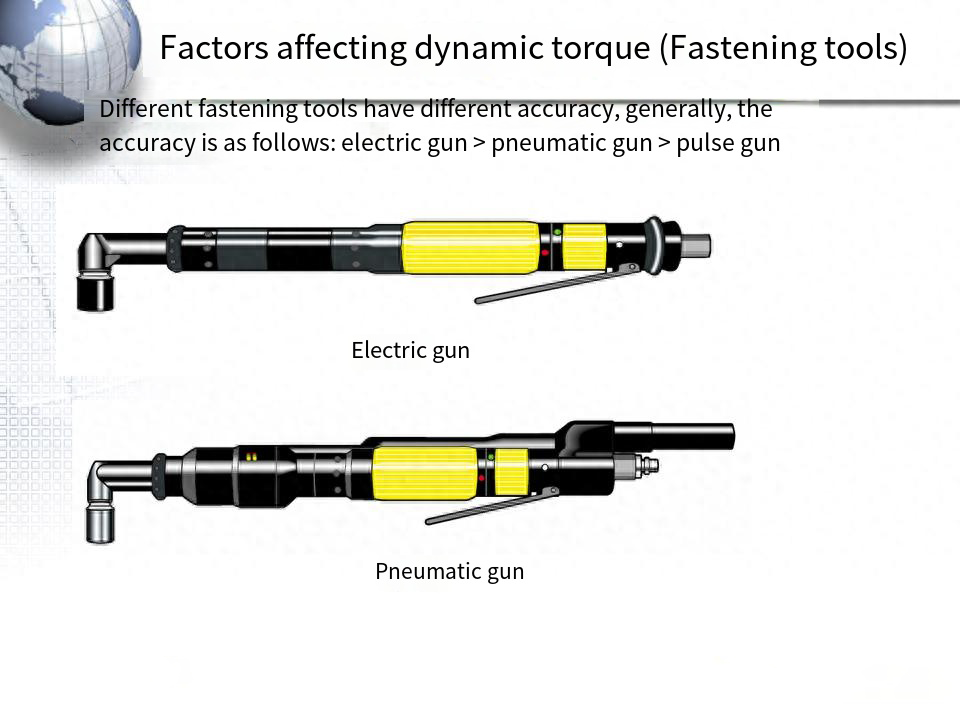

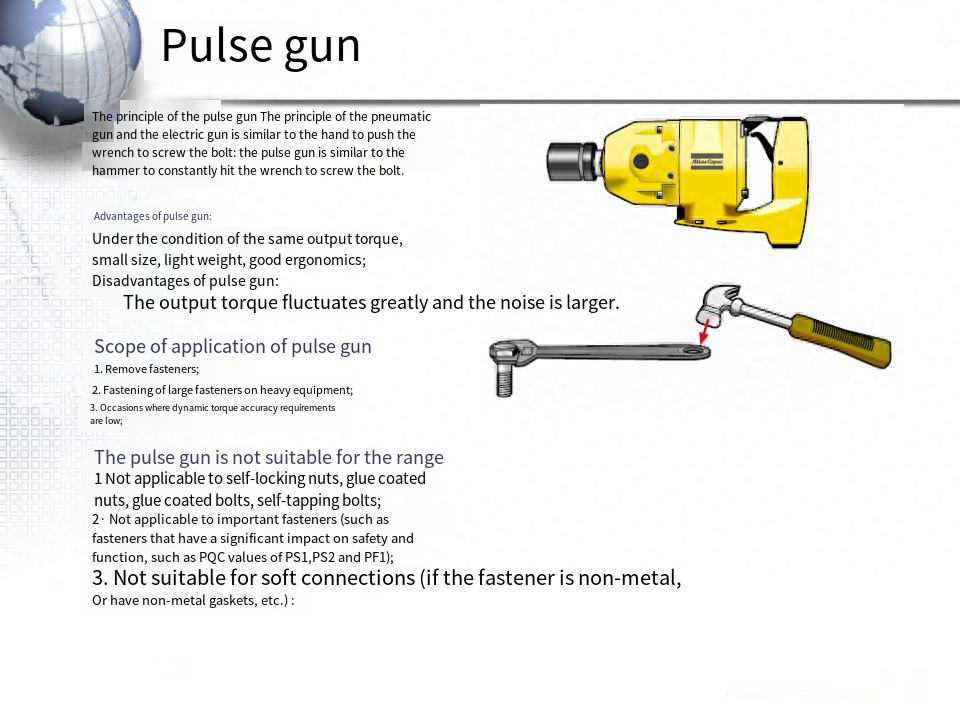

Factors affecting dynamic torque

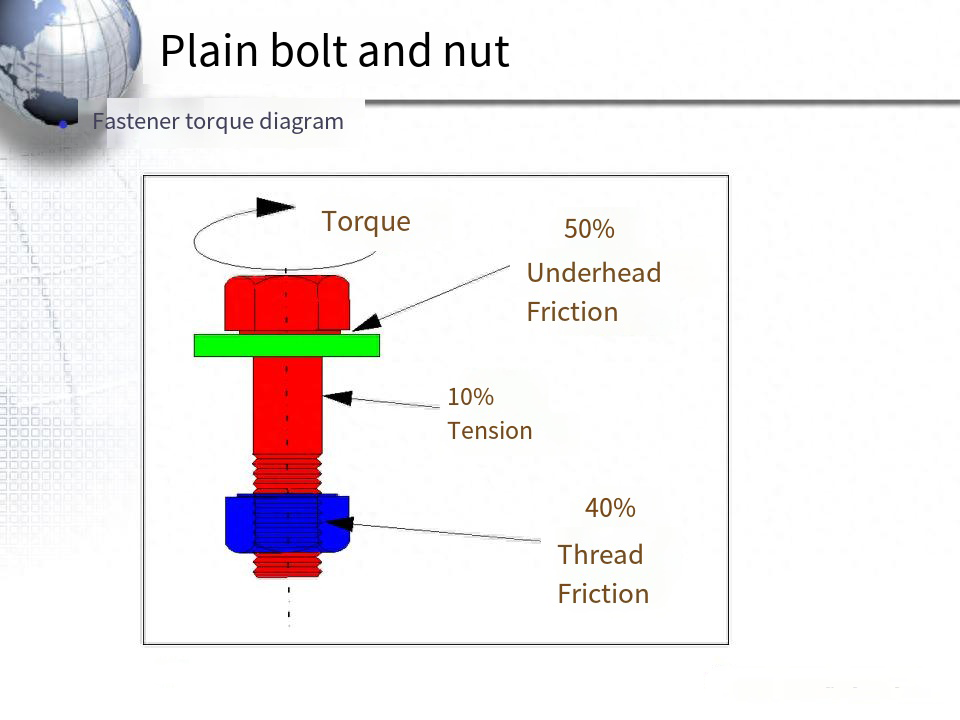

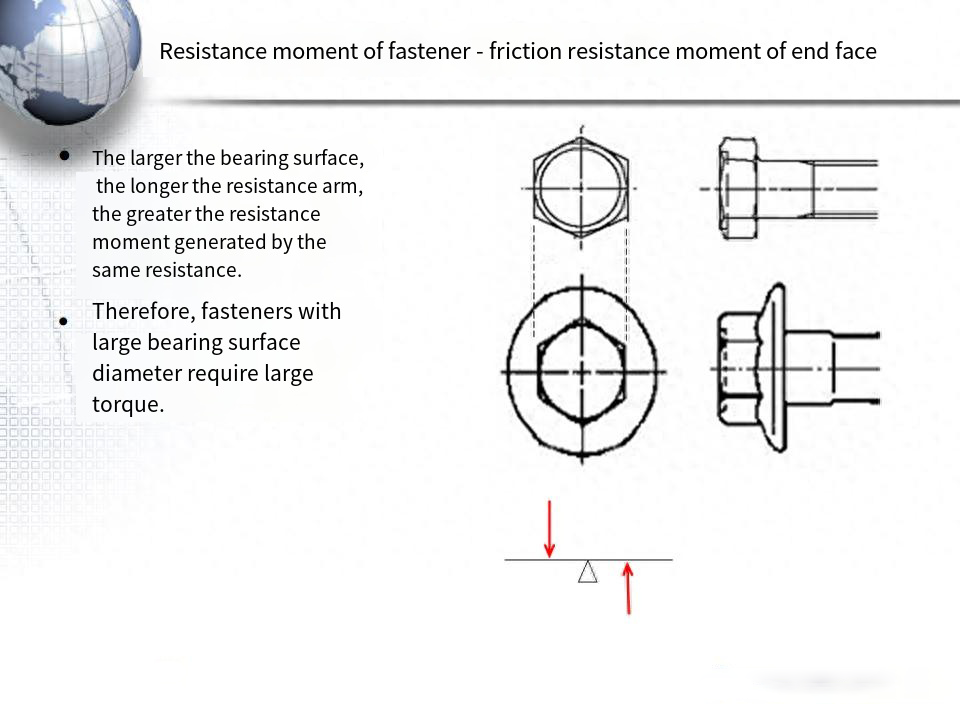

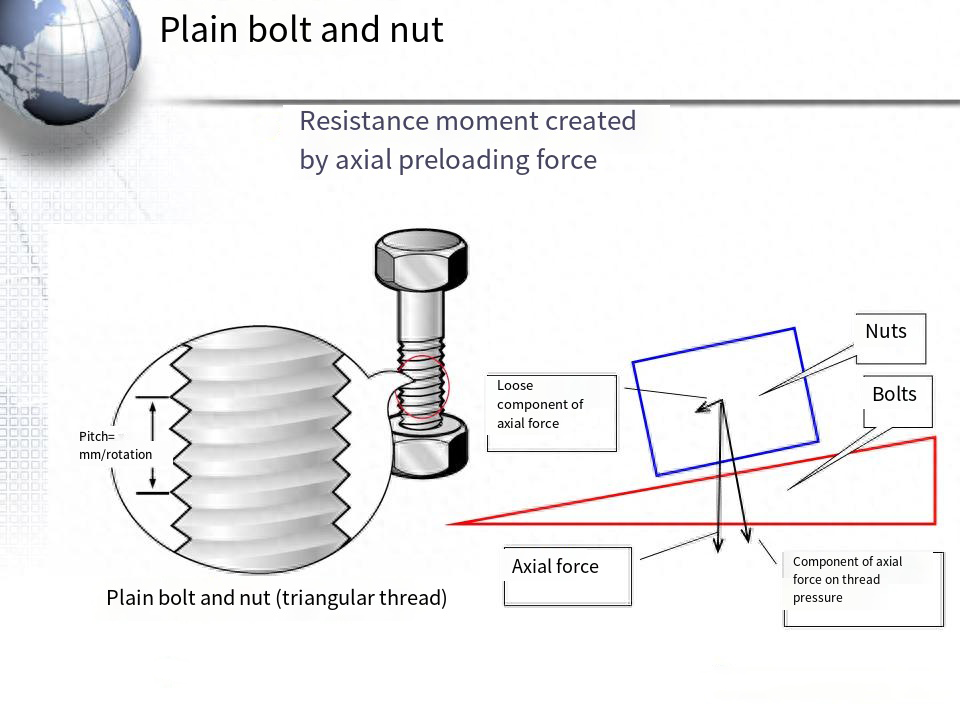

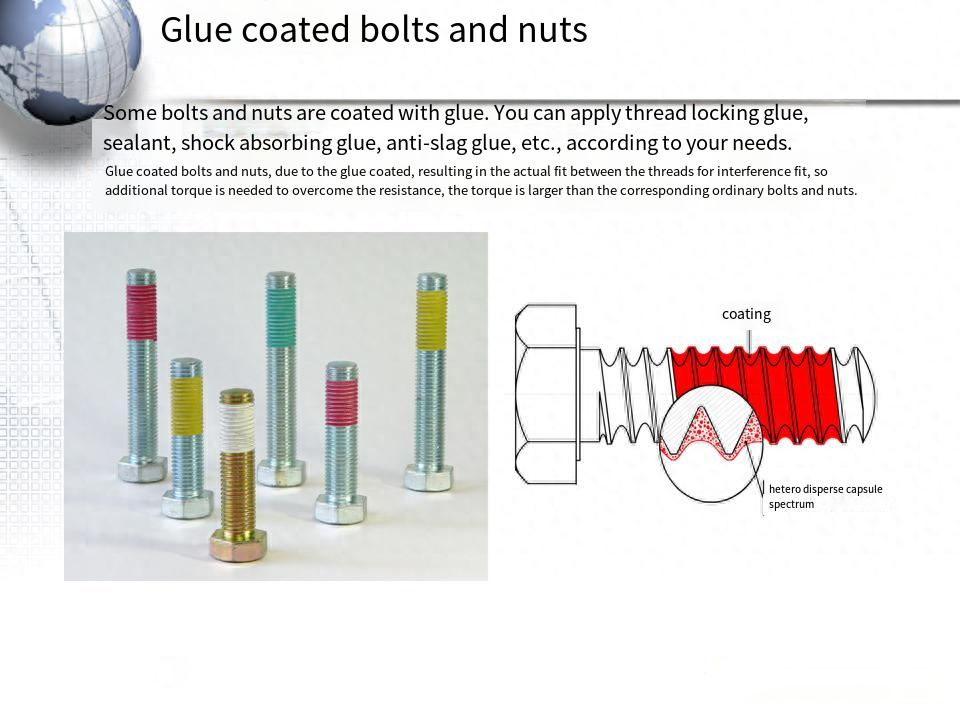

When setting dynamic torque, consider not only fasteners, but also fasteners and fastener tools.The dynamic torque is too small, which is easy to cause loosening and fatigue fracture, and is not conducive to developing the potential of fasteners; The dynamic torque is too large, which is easy to cause fasteners to yield, even break, slip teeth, and be crushed by fasteners.The material hardness, surface roughness, surface friction coefficient and the structure of the fastener will affect the dynamic torque required. At the same time, it is also necessary to consider the strength of the fastener to ensure that it will not be crushed, and then get the maximum torque that the fastener can withstand.Dynamic torque standards need to be determined by both the fastener and the fastener. The minimum dynamic torque should ensure that it is not loose in the process of customer use, and the maximum torque should ensure that the fastener and the fastener do not fail (such as yielding, breaking, slipping, crushing, deformation, etc.).In order to give full play to the performance of fasteners, the axial preload of fasteners should generally be 50 to 75% of the guaranteed load of fasteners.

Post time: Sep-21-2023