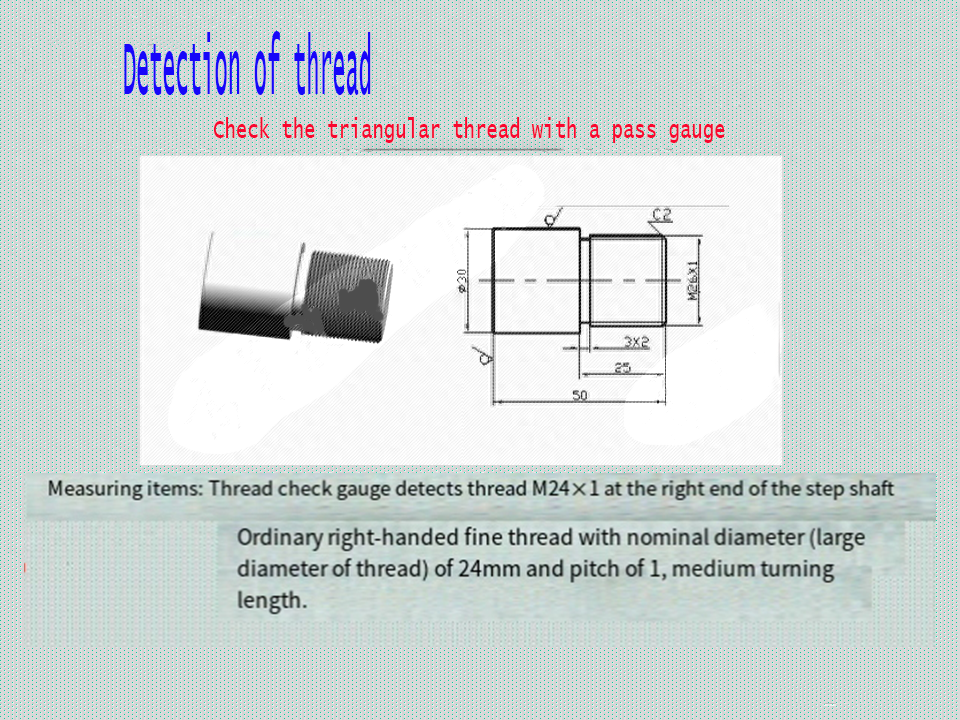

Measurement steps:

1. Clean the measuring tool and measured parts to ensure that there is no iron filings on the surface of the measuring tool and measured parts.

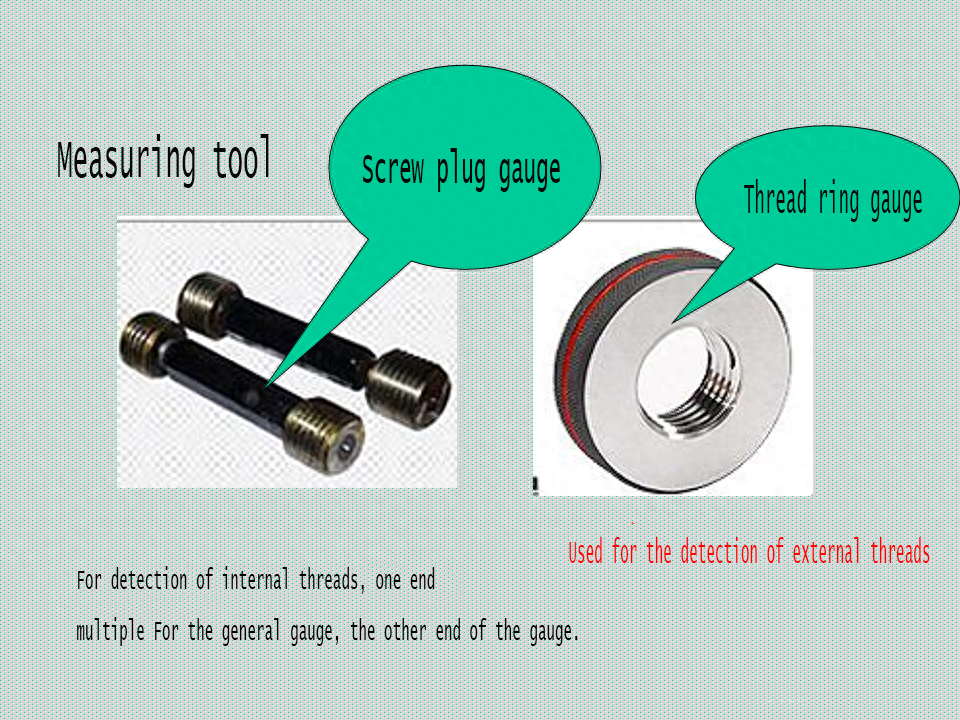

2, then according to the nominal diameter of the measured thread, select M24×1 thread ring gauge.

3, when measuring, if the thread ring gauge can be successfully screwed into the workpiece, and the stop gauge can not be completely screwed, it indicates that the thread meets the accuracy requirements, and the reverse is not qualified.

Test results determine:

Thread ring gauge is usually divided into through end thread ring gauge and stop end thread ring gauge, its meaning is that in the detection of threaded workpiece, through end thread ring gauge should be smoothly threaded into the threaded workpiece, and stop end thread ring gauge should be threaded into the threaded workpiece no more than two pitches, for three or less than three pitches of the workpiece, should not be completely through, only through the amount of screw and stop gauge are in line with the above requirements, it is judged For the thread of the workpiece qualified, if there is a condition is not met, it means that the thread is unqualified.

Use and maintenance of thread gauge

1, thread gauge is one of the precision measuring tools, the use of light, not bump its working face, can not be placed everywhere;

2, the mark of the thread gauge should be correct and clear, and wear gloves when using;

3, when measuring, the thread gauge should be transferred along the axis of the hole, can not tilt;

4, after each use, put into the designated place for storage (dry place);

5, the thread of the thread gauge can not bump against each other;

6, fingers can not extend into the screw gauge inside;

7, can not use the thread gauge as a tool;

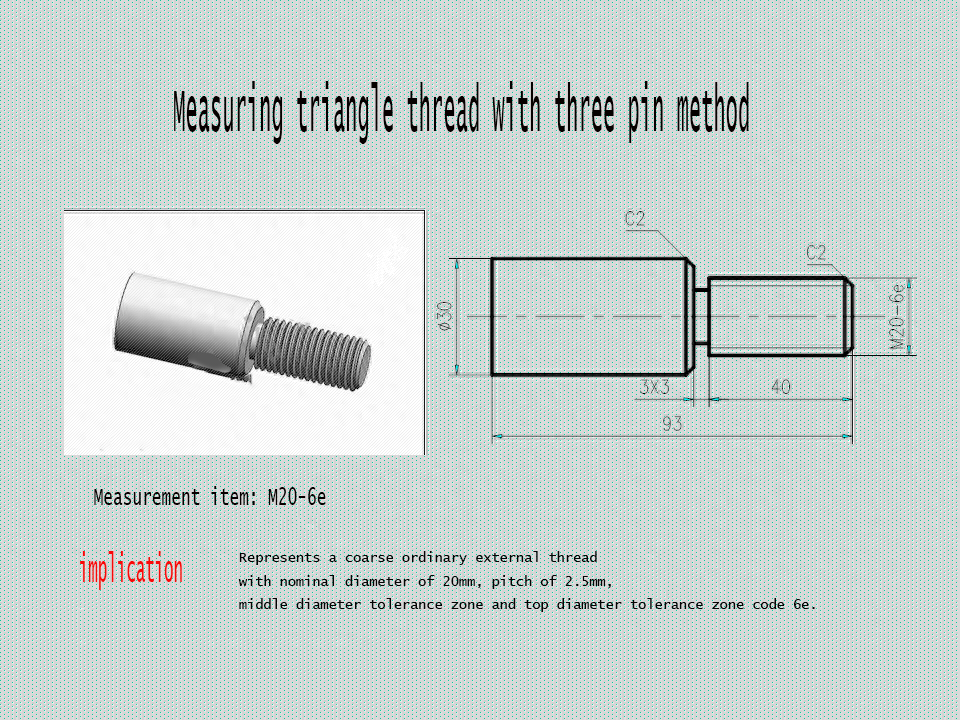

For threads with tolerance requirements for the middle diameter and top diameter of the thread, the focus is on measuring the middle diameter of the thread, usually using the three-pin method to obtain accurate measurement results.

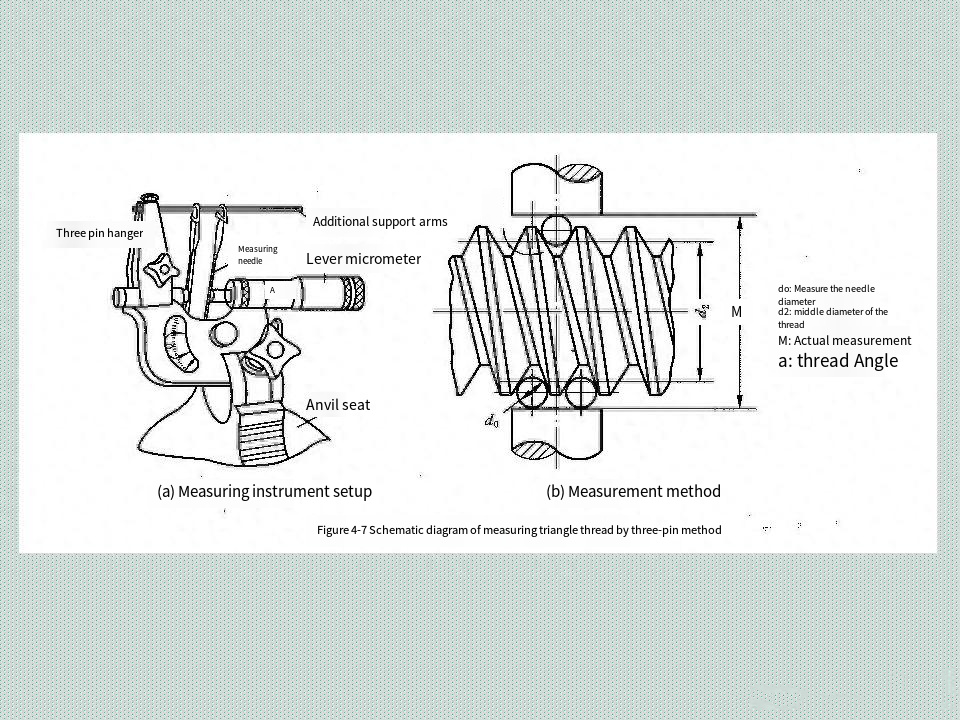

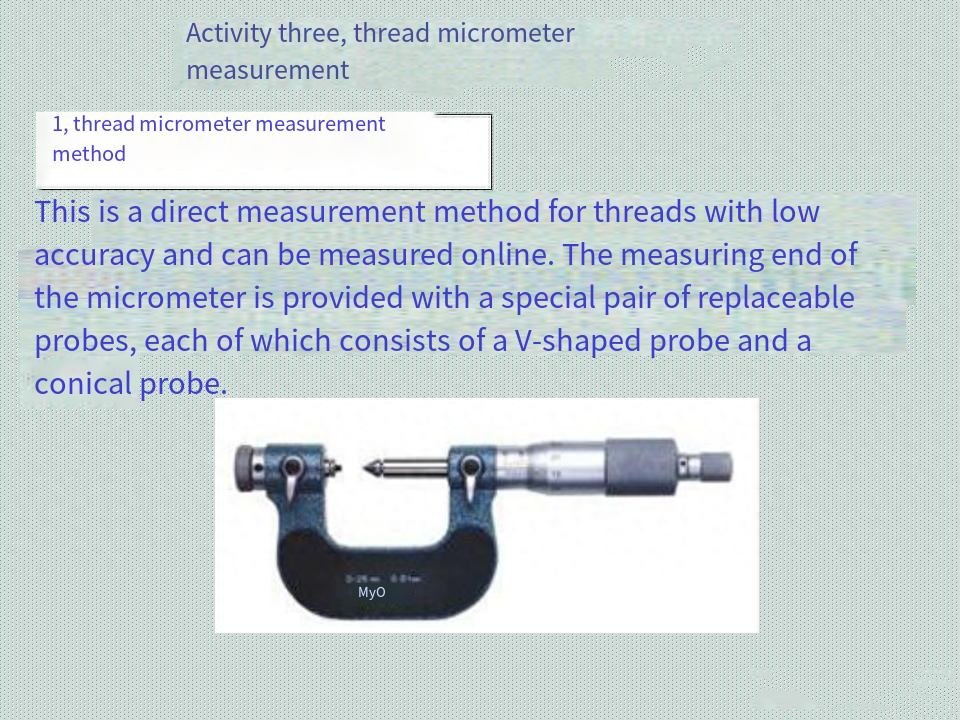

What is the chain baht method, also known as the three-pin measurement method (also known as the three-wire measurement method), can only measure the external thread, is a relatively precise indirect measurement method for measuring the diameter. When used, according to the accuracy of the measured thread, select the corresponding measuring needle accuracy, and its measuring principle is shown in the figure below. It is the use of three precision cylindrical measuring needles with the same diameter into the groove on both sides of the diameter direction of the measured thread, one on one side, two on the other side, the measuring needle and the groove two sides contact, and then use the measuring instrument to measure the distance between the three measuring needles outside the bus bar (span needle distance), and then obtain the single diameter of the measured thread through geometric calculation.

(3) Clean up the measuring needle and the measured thread, and correct the zero position of the micrometer.

(4) Put the three measuring needles in the groove of the human thread, rotate the differential slip on the micrometer, make the probe at both ends contact with the three pins, and tighten the spiral sleeve slip on the micrometer until the three “clucking” sounds are issued, and read the size M, as shown in Figure 4-7B.

(5) Take any point in the same section of the thread perpendicular to each other in two directions, measure the size M, and respectively take 5 measuring points in 5 different places, record the value, take its average value to determine whether the thread is qualified.

(6) At the end of the measurement, wipe the measuring tool clean and put it in the box for safekeeping.

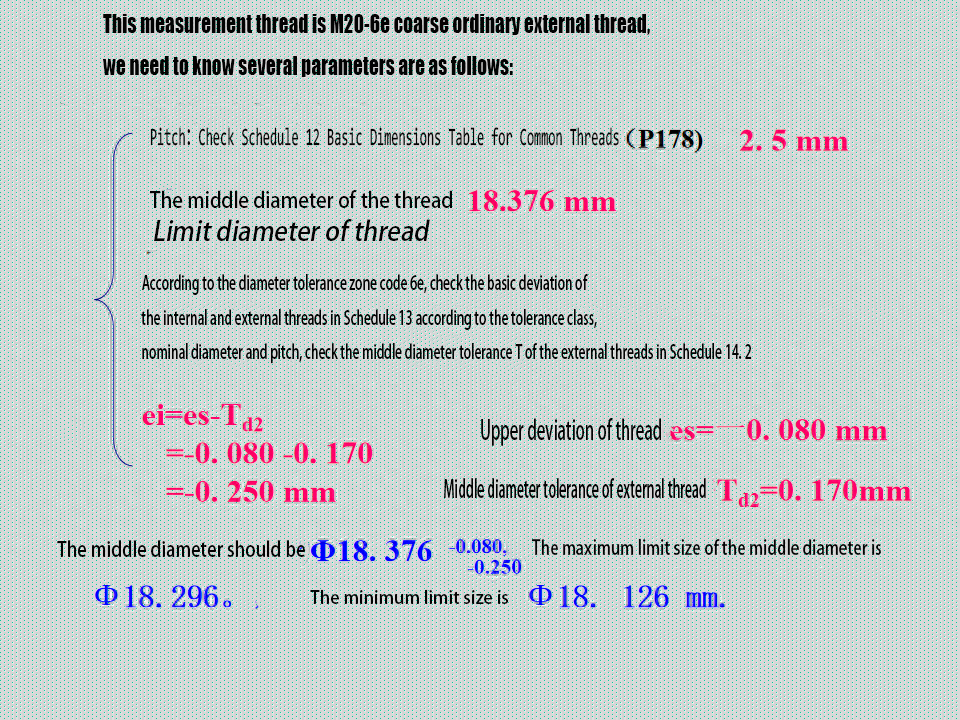

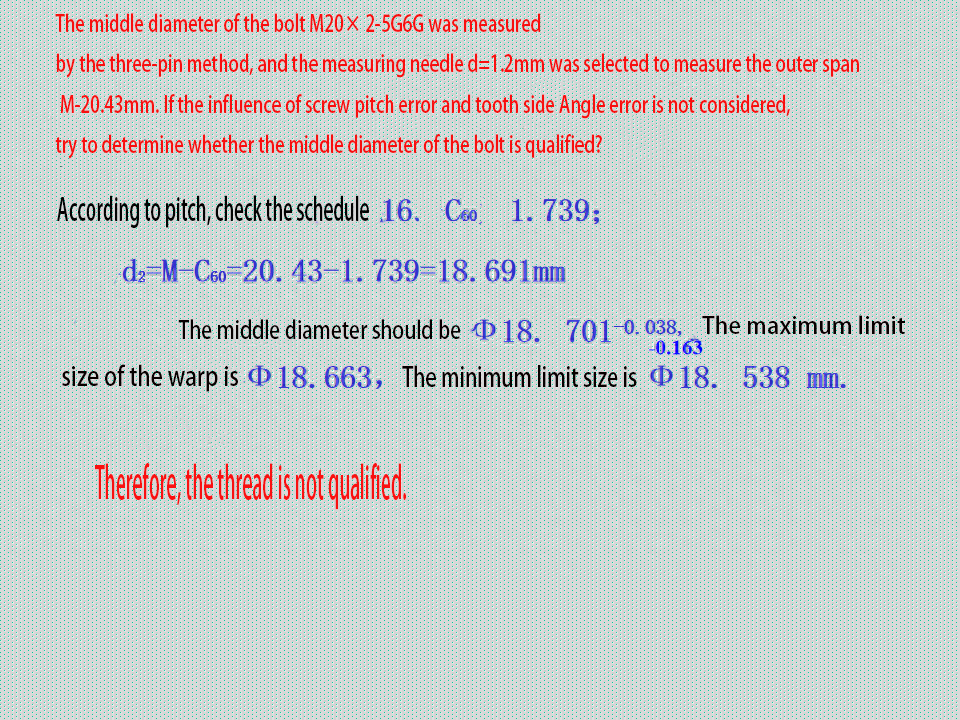

2. Data processingThe mean value of the actual measured 5 data M generation formula d2=M-C60, find the measured thread diameter value d2, where, parameter Co. It can be obtained by referring to the Schedule 16, and judge whether the value of d, is within the limit size range of the middle diameter of the thread, if it is beyond this range, it means that the thread is unqualified.

3. Test reportFollow the steps to complete the measurement and the relevant information of the measured part and the measurement junctionFill in the test report form (Table 4-2)

Post time: Sep-25-2023