-

Thread surface roughness

The surface roughness requirements for threads are 3.2 for qualified products and 1.6 for first class and excellent products. The accuracy of labeling on threads, such as M8X1-6h, requires a relatively high surface roughness. The requirements for con...Read More -

How to determine if the bolts are tightened Torque measurement technology

1.Why do we need to perform static torque testing? In many cases, the torque value during the production process and the torque value detected during offline testing are different. For example, the torque displayed on the controller is 100Nm, and the torque value dete...Read More -

Thread-turning process

Thread turning is a very common and complicated problem in machining. The requirements of thread turning are higher than other ordinary turning operations, and the cutting force generated during turning is generally large.When turning thread, due to the influence of thread ri...Read More -

Fastener processing technology

Other processBlanking, straightening (straightening), milling machine processing, drilling, milling, and so on.bolt:Small specification bolts (M16 and below) with a diameter of 1- and 8.8, such as hexagonal head boltsand hexagonal flange boltsRaw...Read More -

Tolerance detection

9.4 ThreadMeasurement 9.4.2 Single Measurement There are many methods for single measurement of thread, the most typical one is to use the universal tool microscope to measure the diameter, pitch and half Angle of thread. The tool microscope is used to ...Read More -

Extrusion tap

Coolant lubricant In the process of internal thread cold extrusion, the selection of suitable cooling lubricant can greatly reduce the direct wear of the working surface of the extrusion tap and extend its life. Extrusion tap will be subjected to a lot of friction resista...Read More -

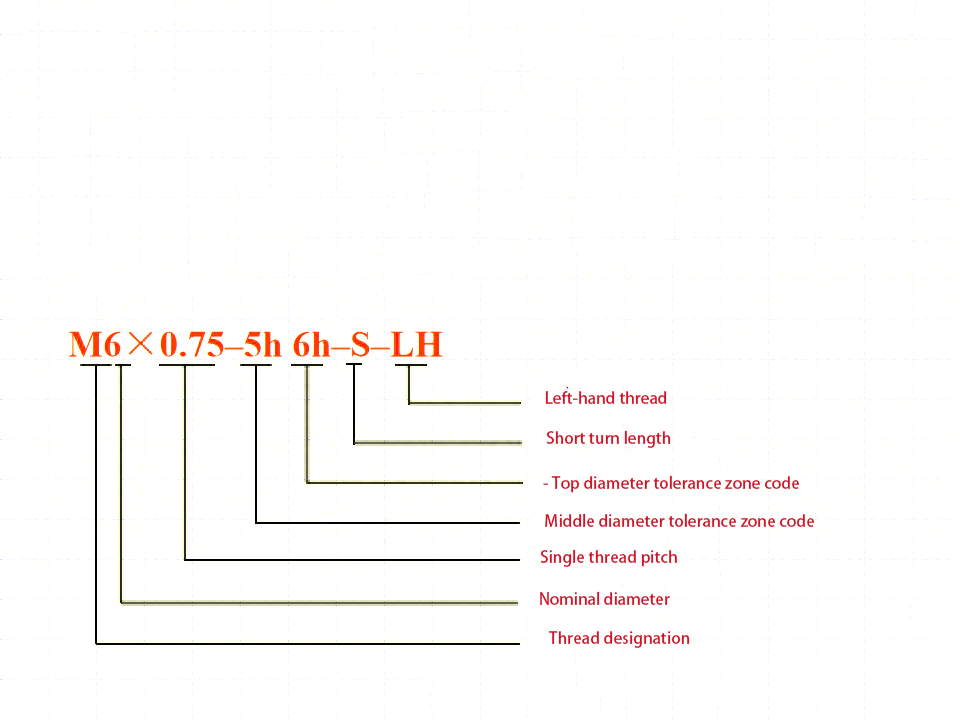

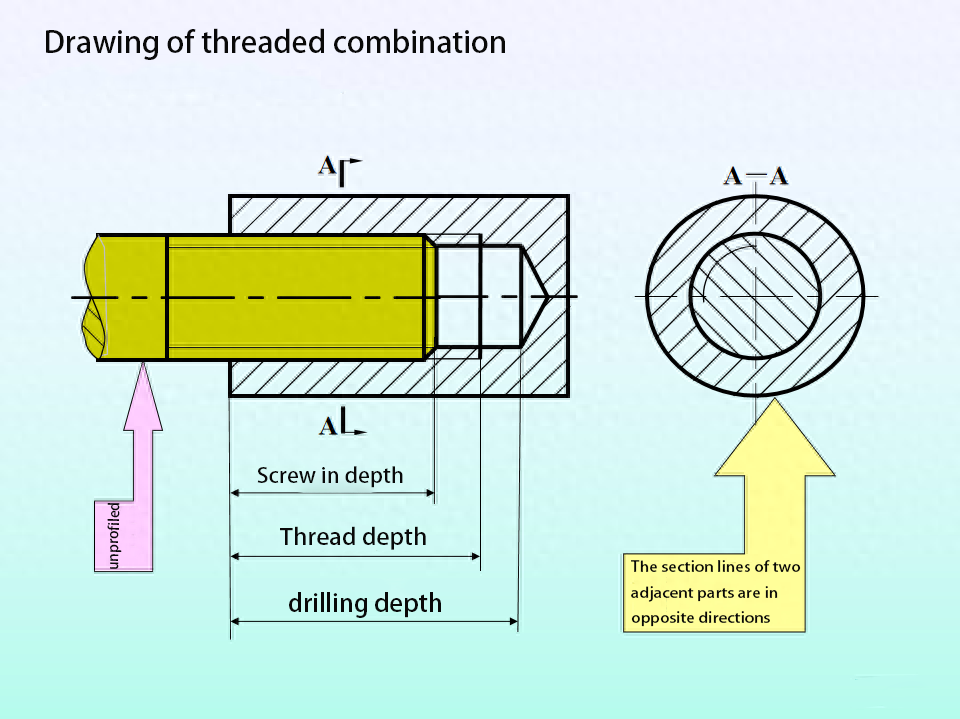

Representation of thread

Description Summary The internal thread is generally open to indicate, In the non-circular view, the thread base (large diameter) is represented by a thin solid line (not drawn into the chamfer area);The tip of the thread (small path) and the thread ter...Read More -

Thread drawing and marking

Chapter VII. Special representations in mechanical drawings 07.1 Thread 7.2 Thing method of the thread is stipulated 7.3 Method for marking thread At present, various design fields are CAD download on the Internet, looking for a humanized, intelligent professional software, a variety of plug-in...Read More -

Surface roughness of thread

The surface roughness requirements of the thread are 3.2 for qualified products and 1.6 for first-class and excellent products. Mark on the thread such as M8X1-6h accuracy, to achieve a relatively high surface roughness, connection and fastening with the thread, the requirements are relatively l...Read More

- Email Support hbjtzz@126.com

- Call Support 0086 13313100548