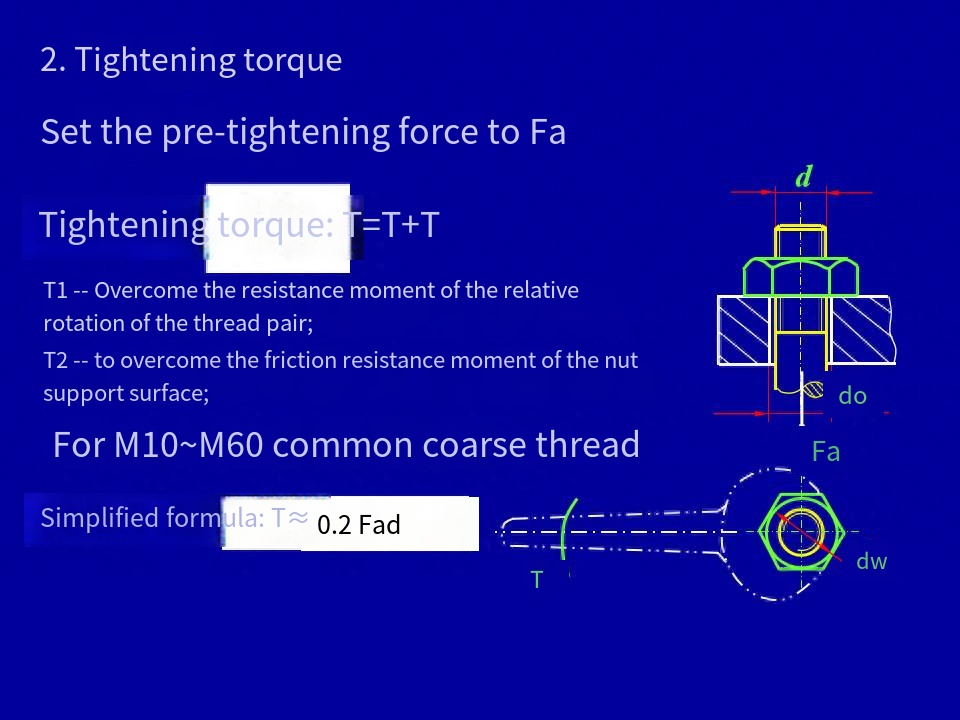

1. Pre-tightening of thread connectionBefore the action of the working load, the screw is subjected to the action of the pre-tightening force.

1. The purpose of pre-tightening

1) Increase the stiffness of the connection

2) Increase tightness

3) Improve the ability to keep loose

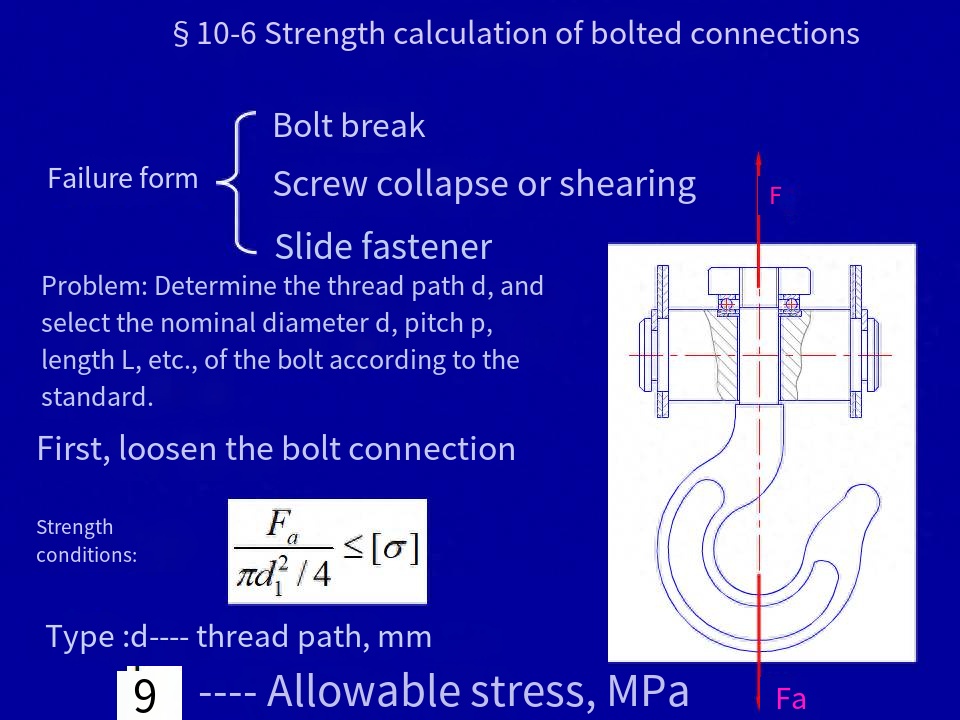

Determination of residual preload:1) No change in working load:FR FR= (0.2~0.6)2) The working load changes:FR= (0.6~1) F3) There are tightness requirements:Fp FR=(1.5~1.8)

$10-7 Materials and allowable stresses of bolts1. Bolt materialBolts are classified according to their mechanical properties, and the national standard stipulates:Bolts 3.6, 4.6, 4.8, 5.6, 5.8, 6.8, 8.8,9.8, 10.9, 12.9Nuts 4, 5, 6, 8, 9, 10, 12

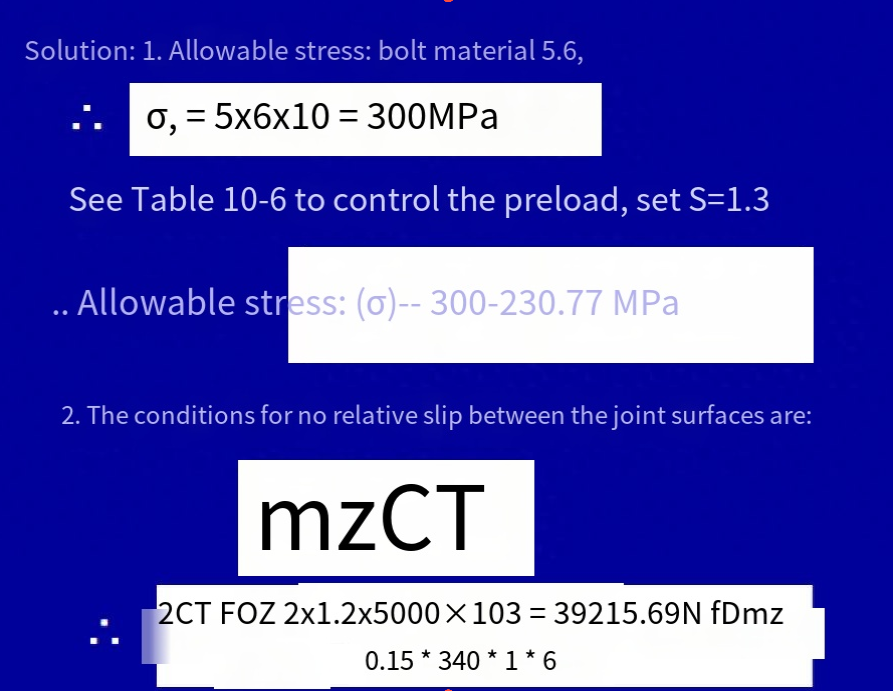

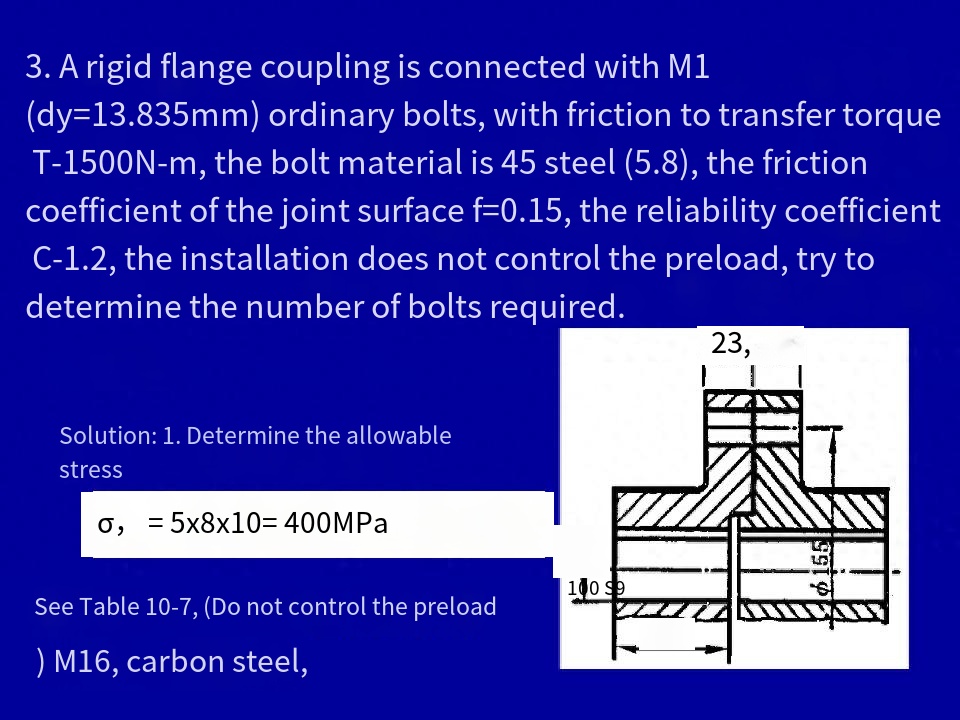

2. The meaning of bolt performance grade code:The e first number: indicates the tensile strength limit of the bolt material. 1/100 of that.σ= first digit x 100Second digit: indicates the yield limit of the bolt material. Ten times the strength limit σ.Sigma. = First digit x second digit x 10Example: Class 4.6 boltσρ=4×100-400MPa, σ, =4×6×10-240MPa3. Allowable stress of threaded connectionSee textbook Tables 10-6 and 10-7

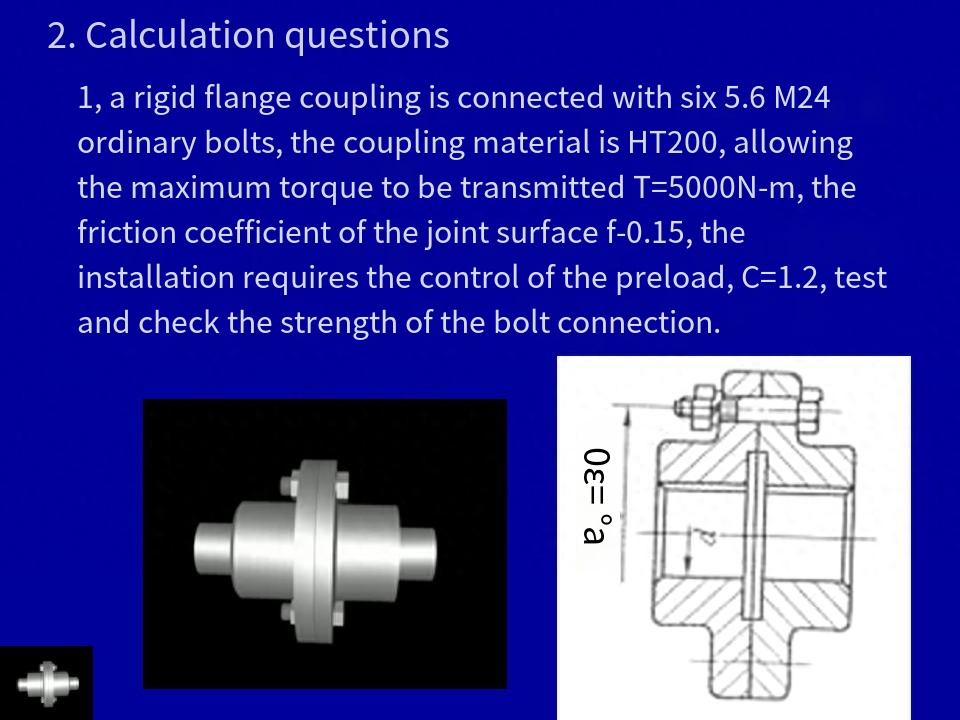

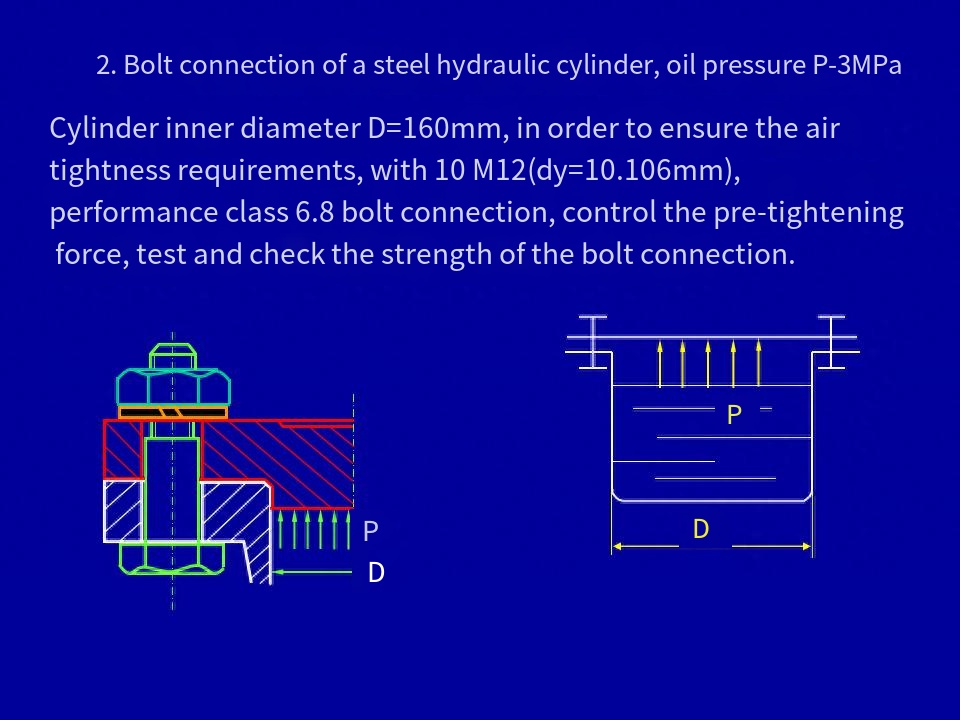

2. Calculation questions

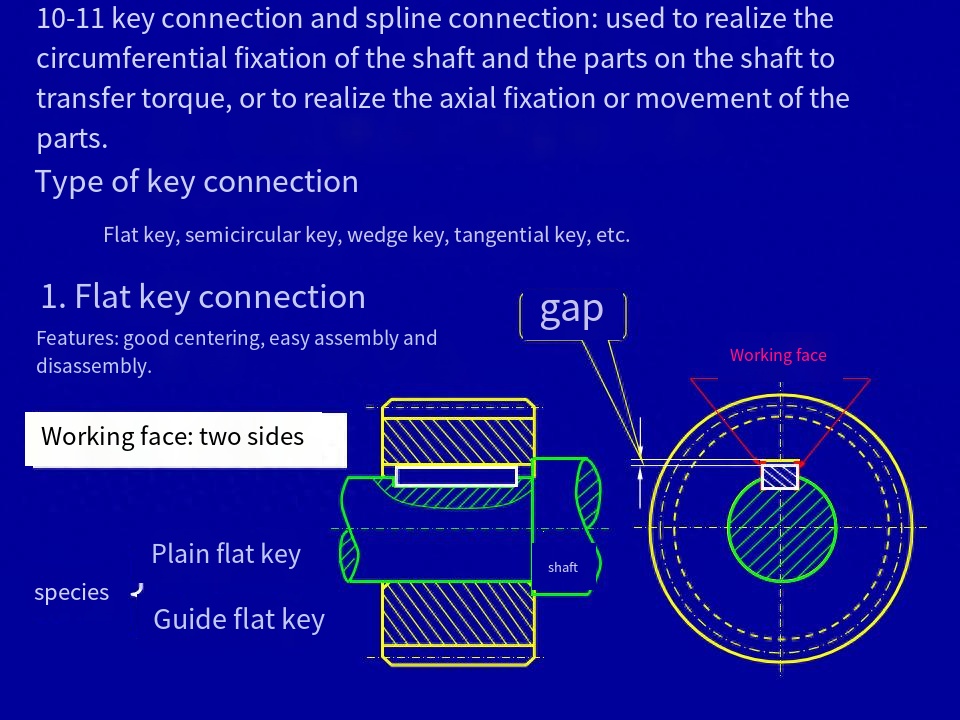

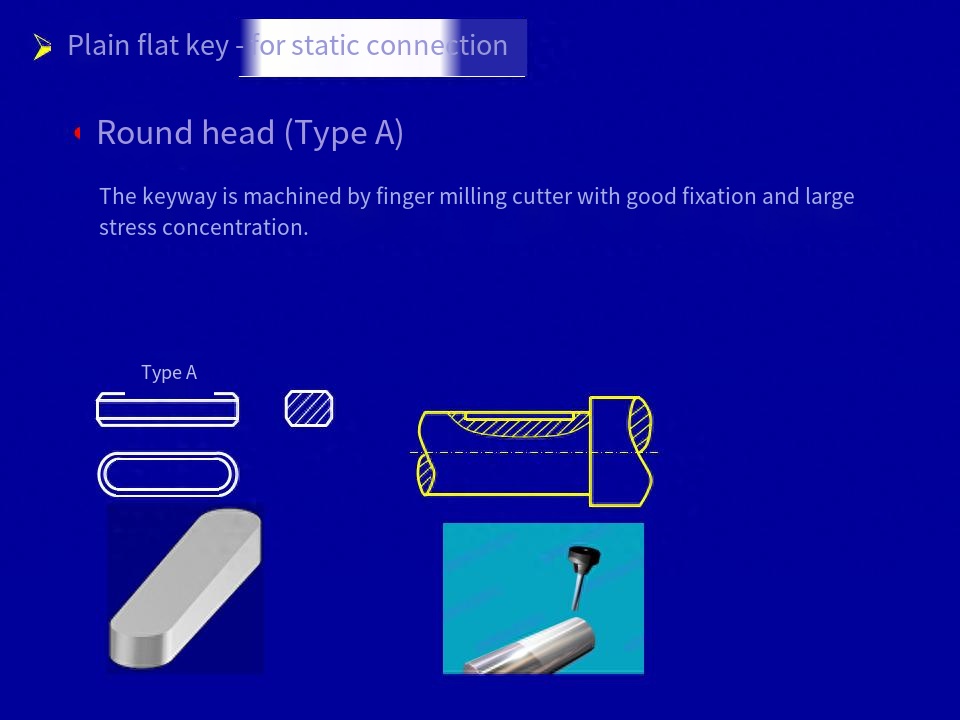

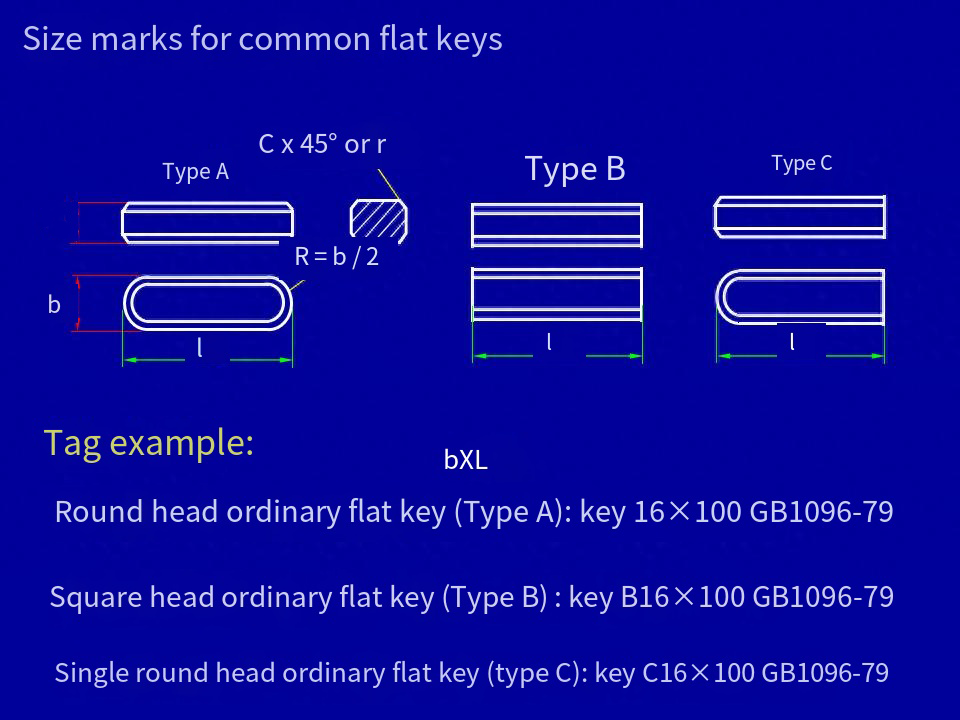

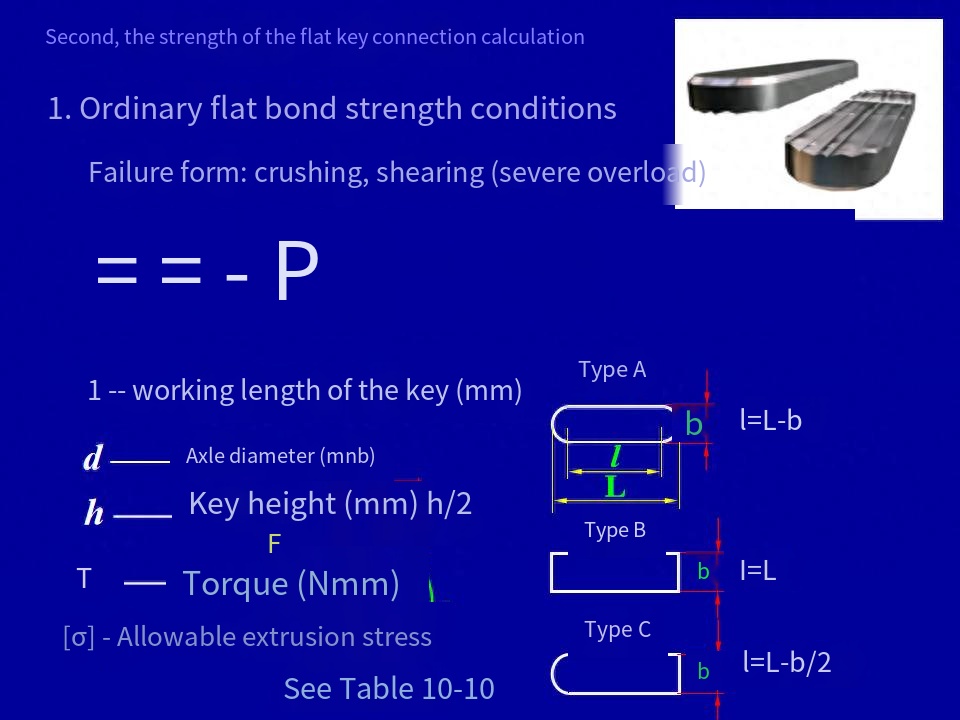

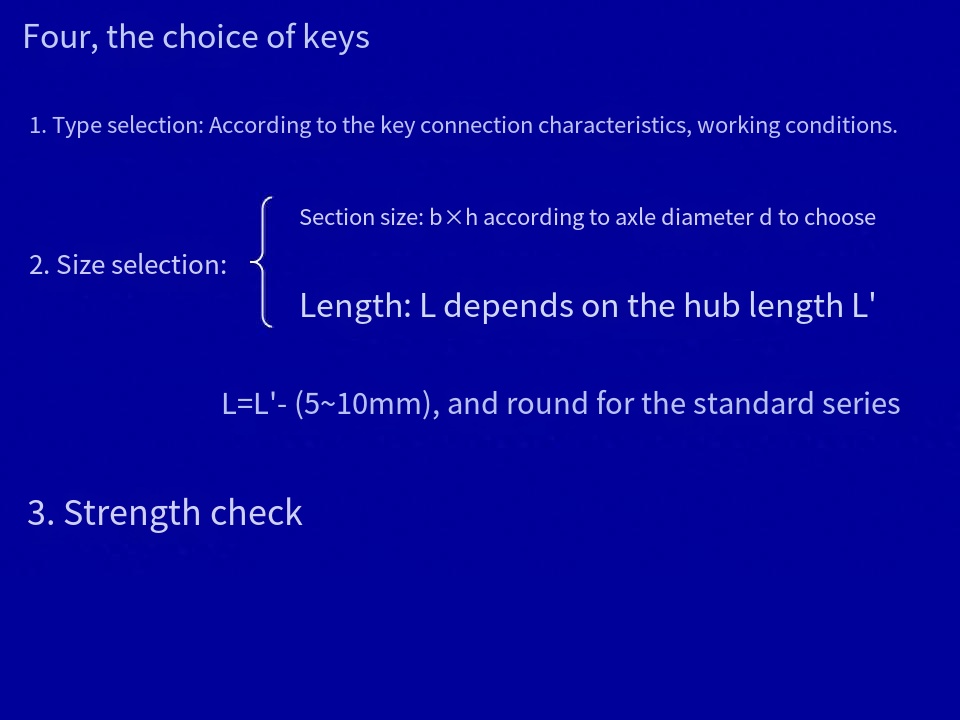

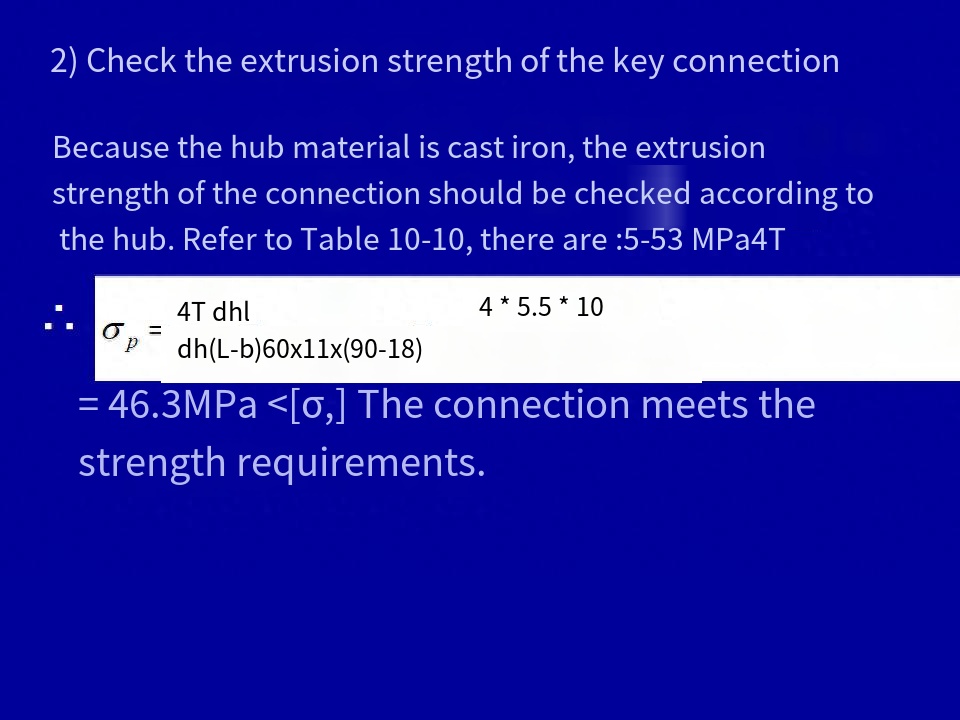

A cast iron straight tooth cylindrical gear through the key and a steel shaft connection, the shaft section diameter at the gear d=60mm, hub length L’=100mm, the transmitted torque T=5.5×105N.mm, a little impact in the work, try to design this key connection.Solution: 1) Determine the material, type and size of the key because the hub is made of cast iron, the material of the key can be selected 45 steel, and there is no axial movement between the gear and the shaft, so the A-type ordinary flat key is selected.According to the axle diameter d=60mm, hub length 100mm, see Table 10-9,Take :b=18mm, h=11mm, L=90mm.

Post time: Sep-13-2023