The surface roughness requirements of the thread are 3.2 for qualified products and 1.6 for first-class and excellent products. Mark on the thread such as M8X1-6h accuracy, to achieve a relatively high surface roughness, connection and fastening with the thread, the requirements are relatively low, generally non-standard tolerance and roughness, with die tap. Most of the threads are non-standard roughness, such as marked thread marked roughness is generally 3.2. The marks are in the upper right corner of the drawing.

The concept of surface roughnessSurface roughness refers to the small spacing of the machined surface and the unevenness of the small peaks and valleys. The distance (wave distance) between the two peaks or two valleys is very small (below 1mm), and it belongs to the microscopic geometry error.Specifically refers to the micro peak and valley Z height degree and spacing S condition. Generally according to S points:S<1mm for surface roughness;1≤S≤10mm is waviness;S>10mm for f shape.

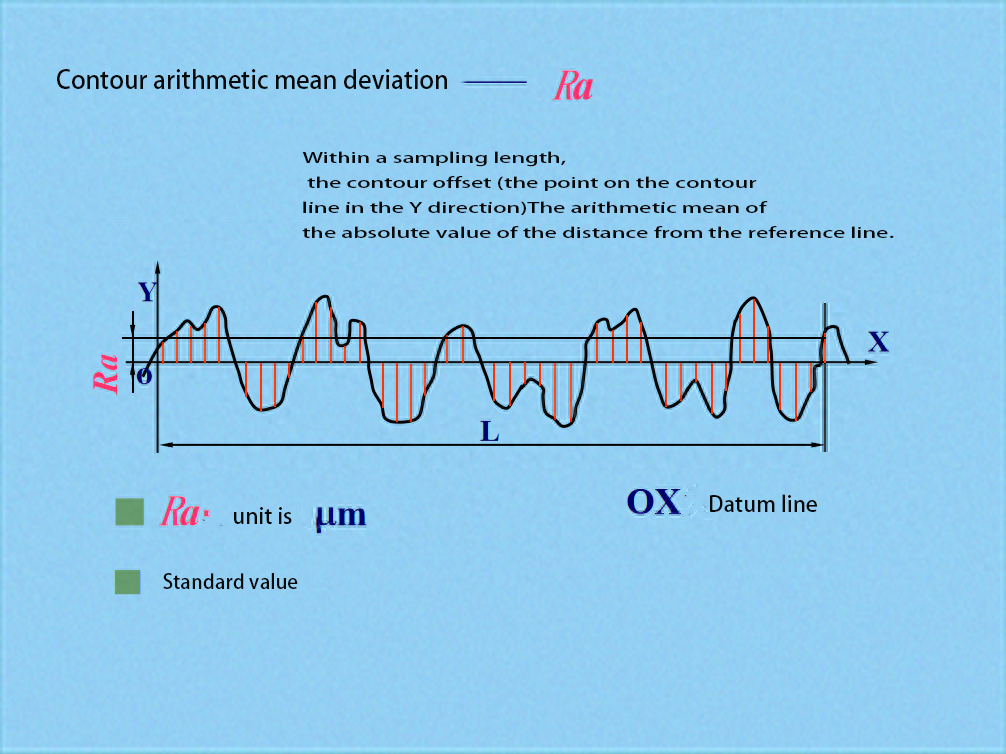

The national standard stipulates that three indicators are commonly used to evaluate the surface roughness (unit is um) : the average arithmetic deviation Ra of the profile, the average height Rz of the unevenness and the maximum height Ry, and the Ra index is used in actual production. The maximum microscopic height deviation of the profile Ry is commonly used in Japan and other countries to represent Rmax symbols, and VDI indicators are commonly used in Europe and the United States.

(1) Threads and fasteners

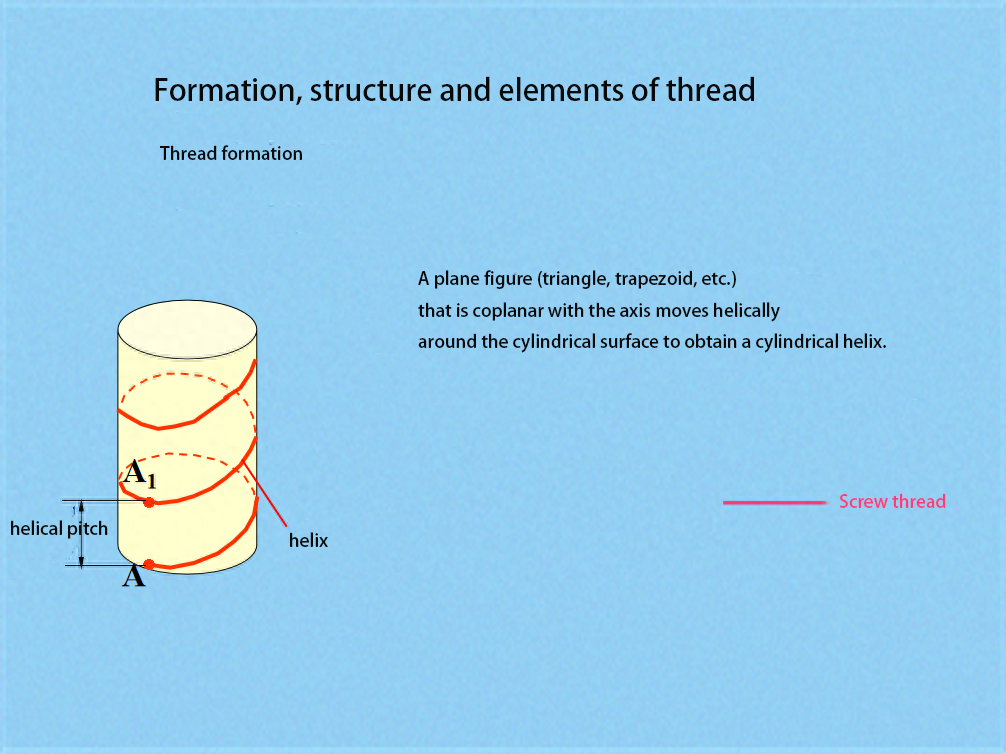

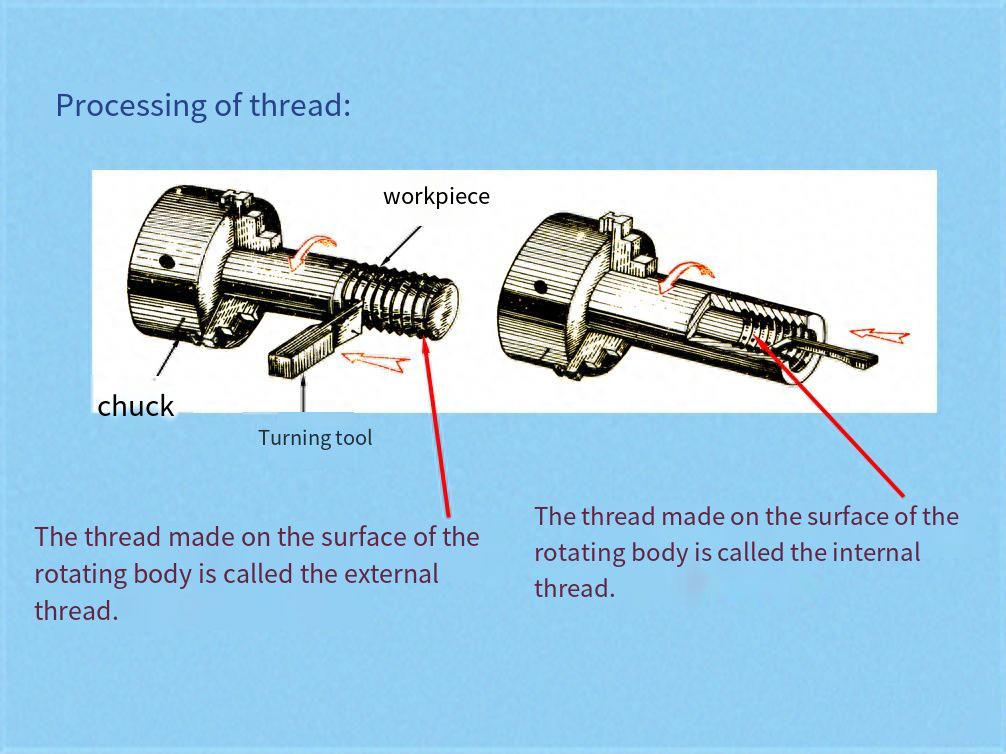

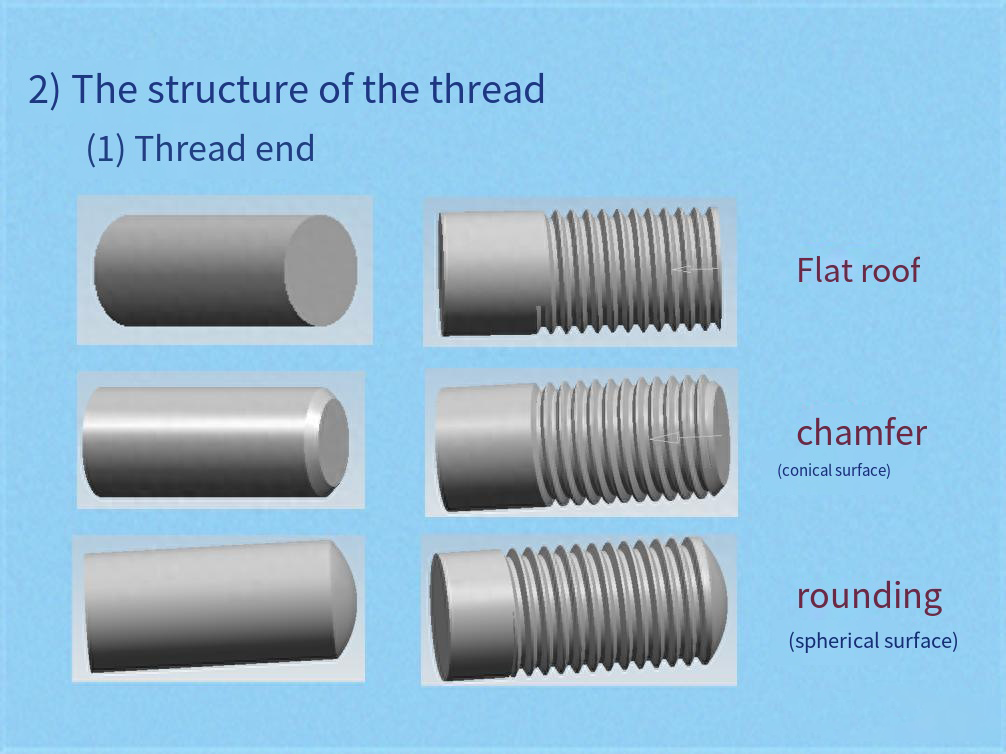

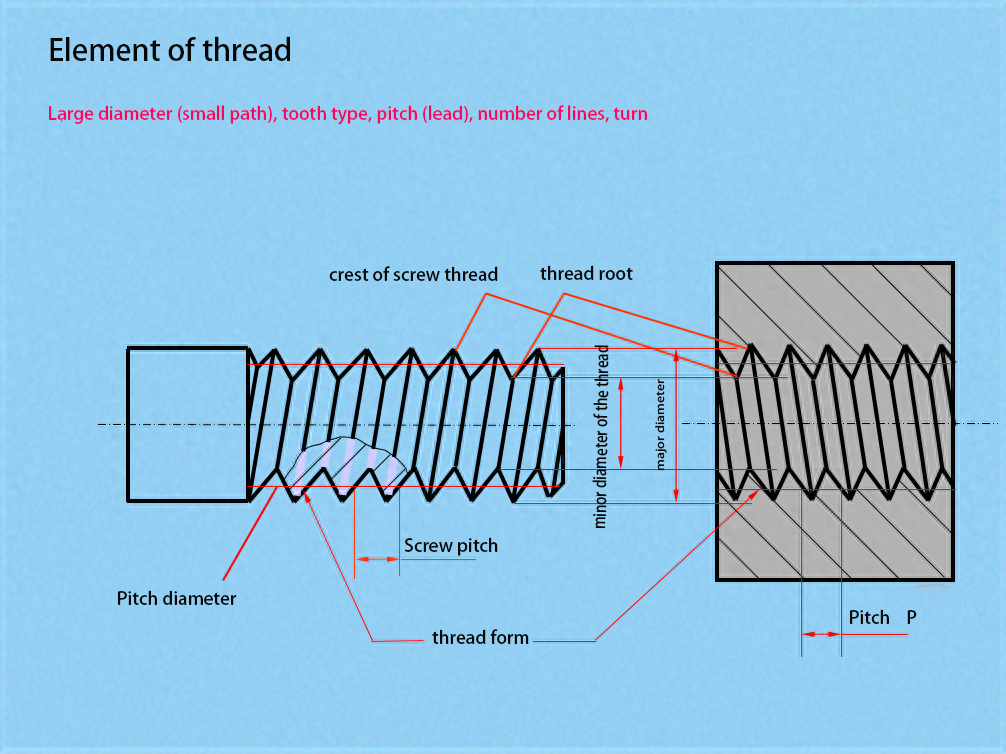

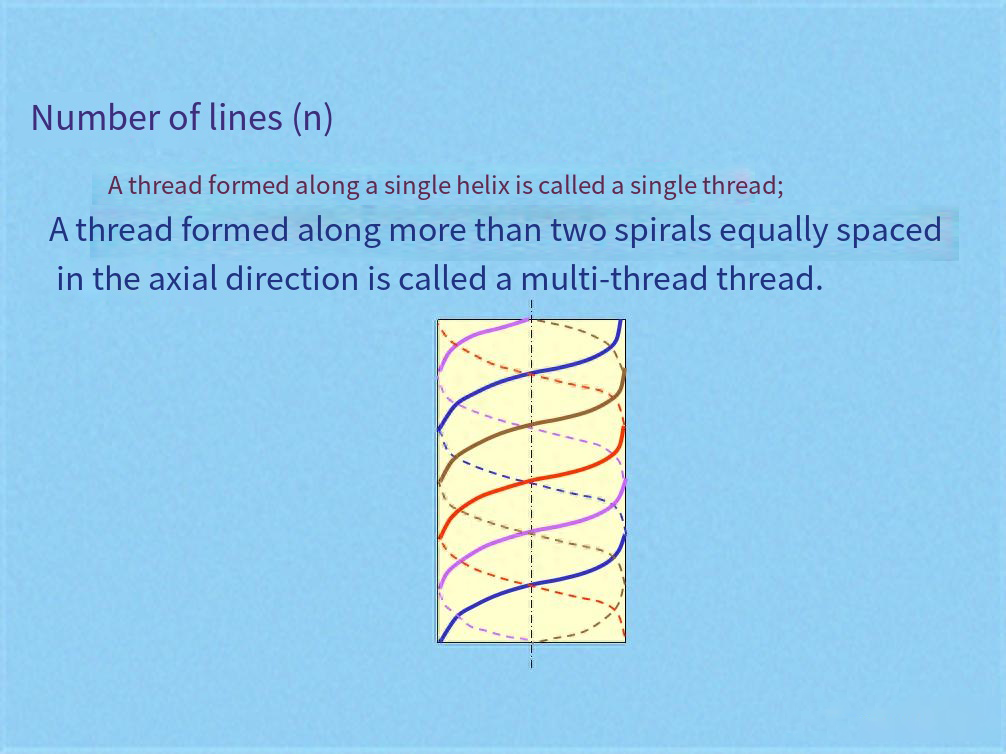

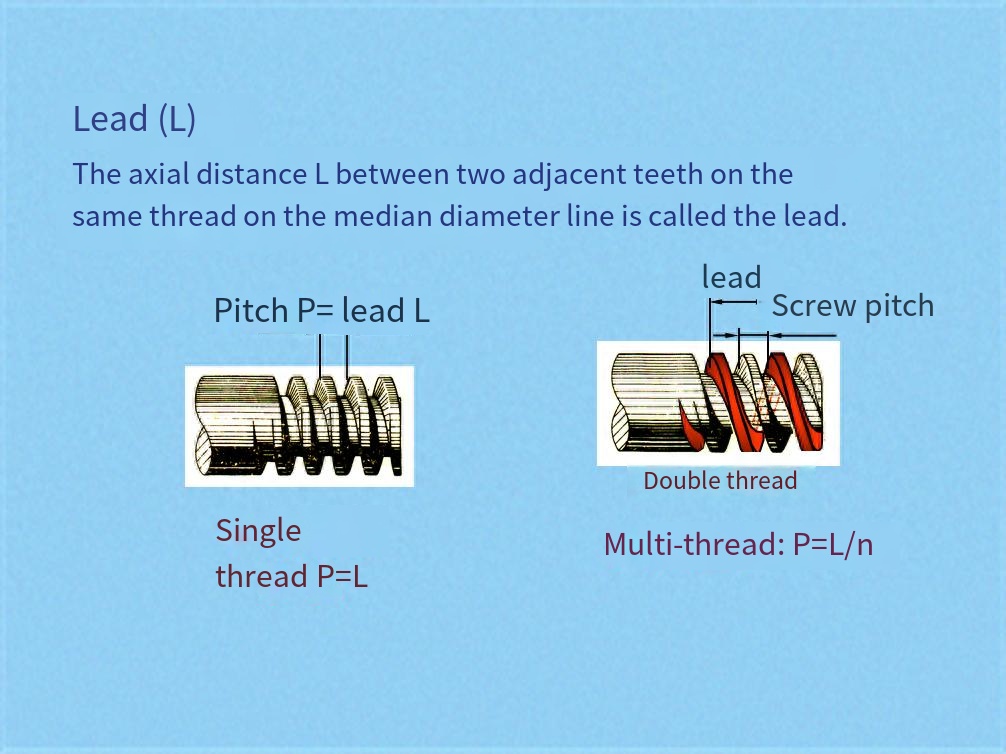

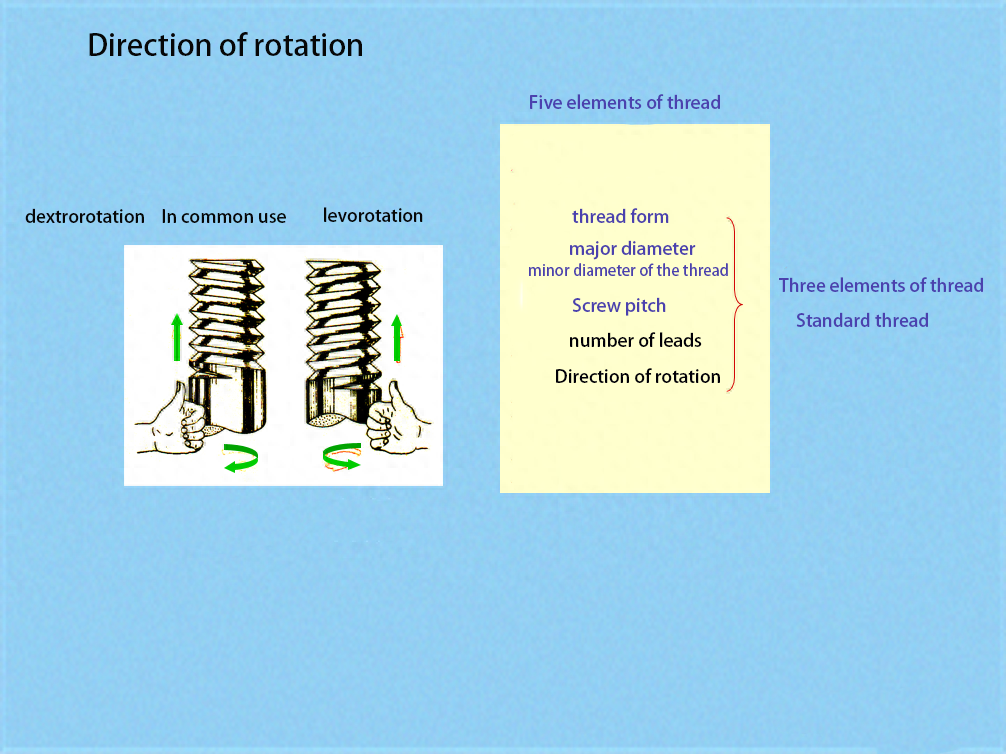

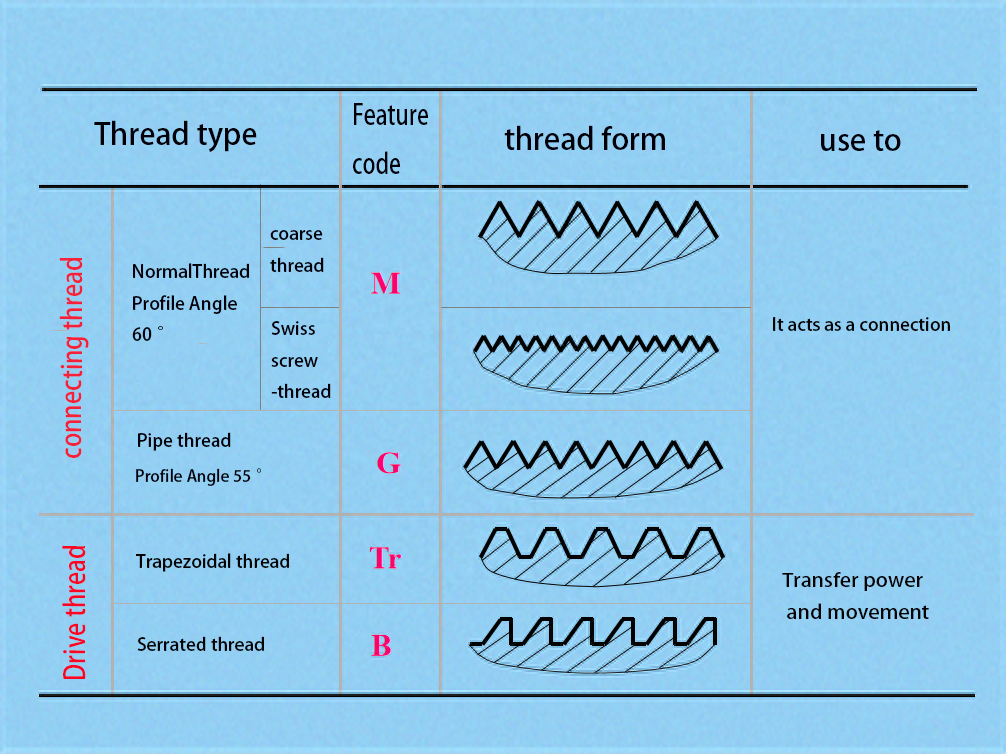

1. Formation, structure and elements of threadSecond, the type of threadThird, the specified drawing method of thread4. Marking of threadFive, threaded fasteners

Second, the type of thread

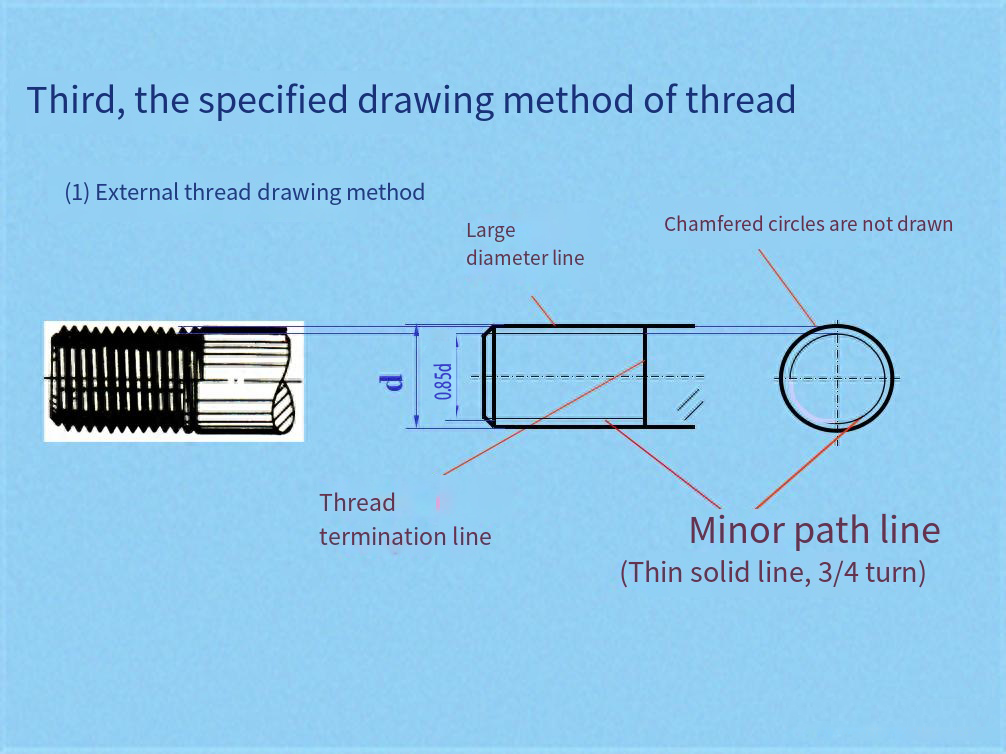

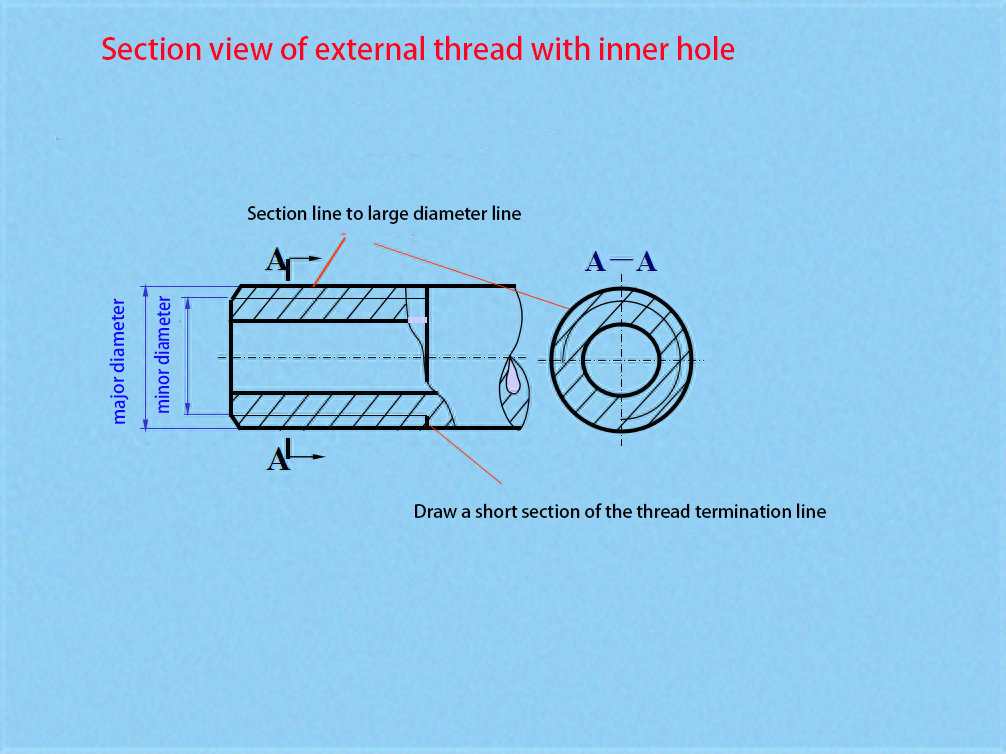

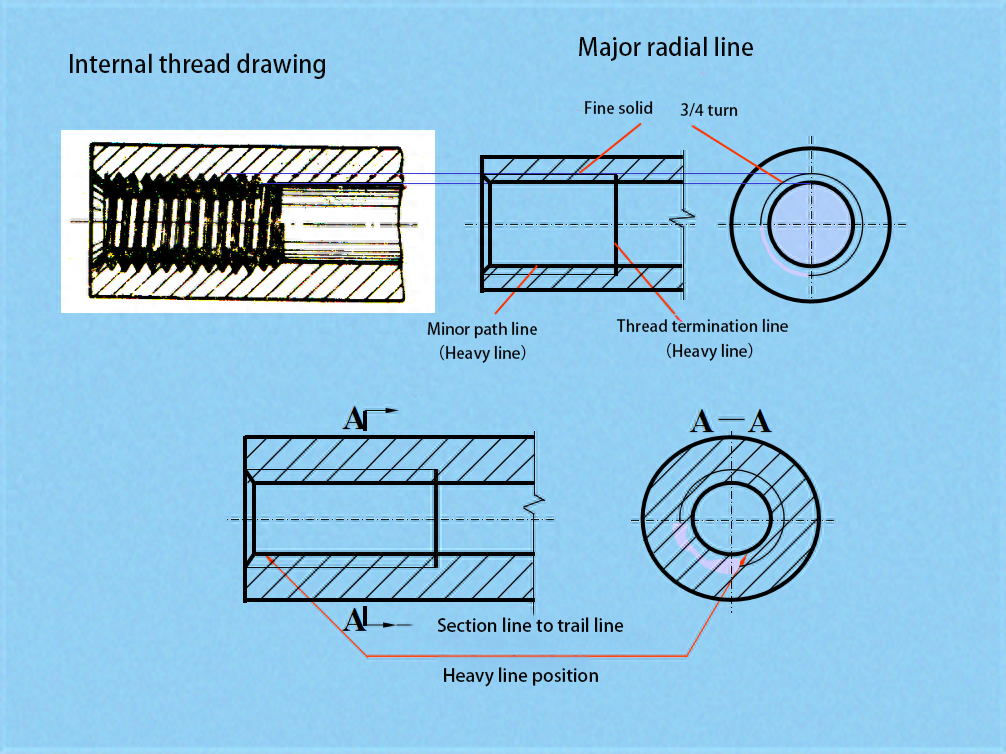

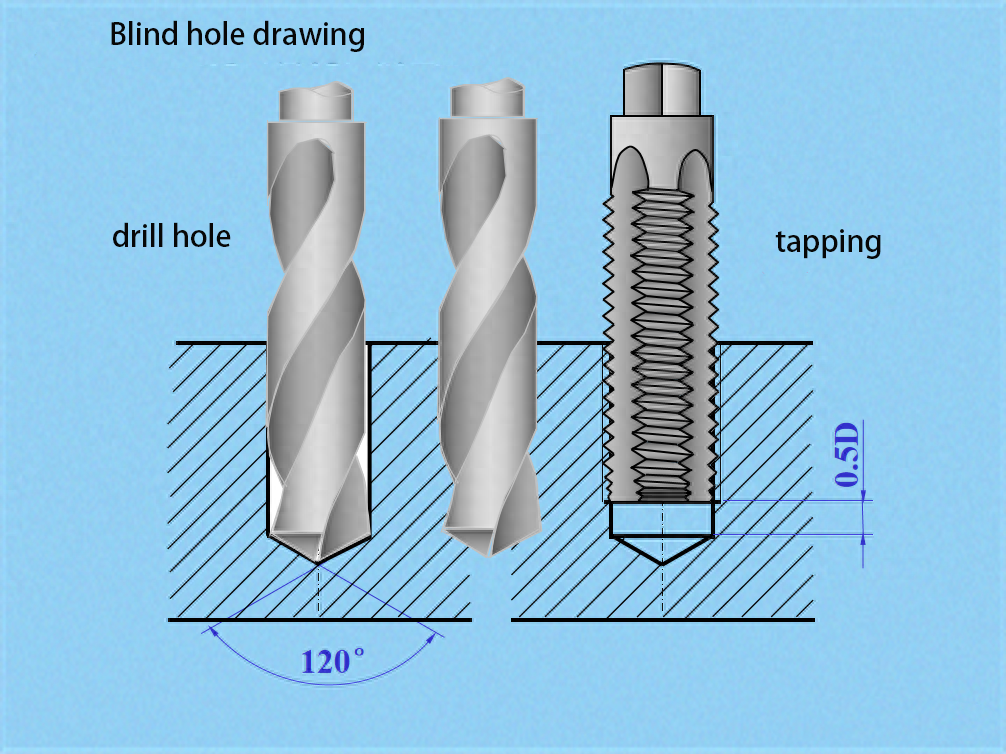

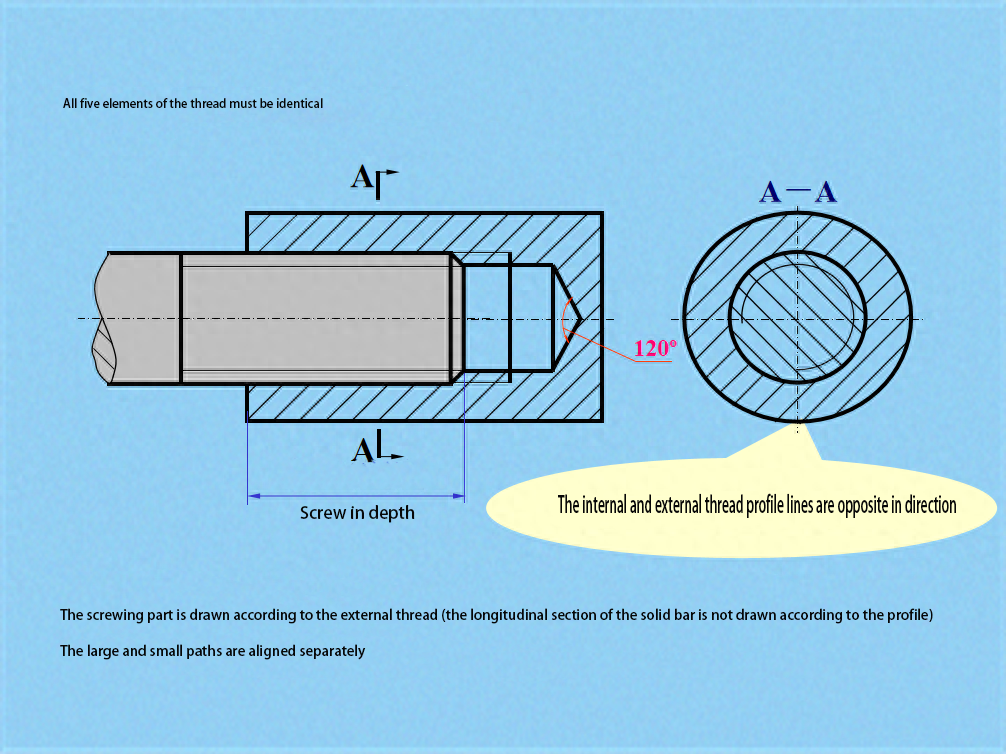

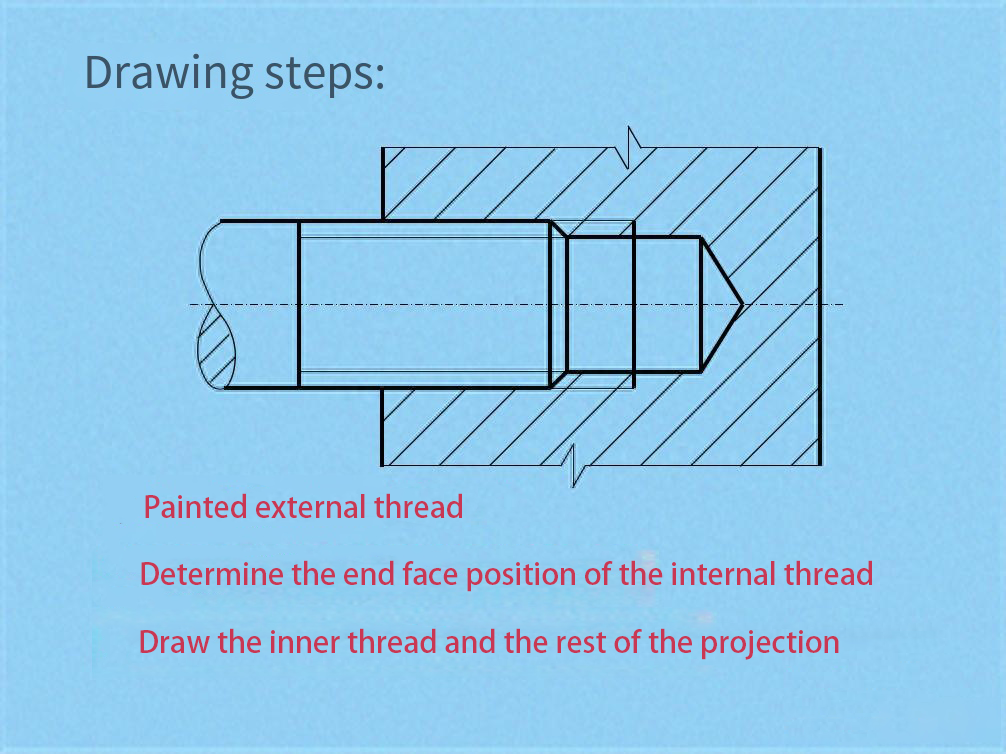

Third, the specified drawing method of thread

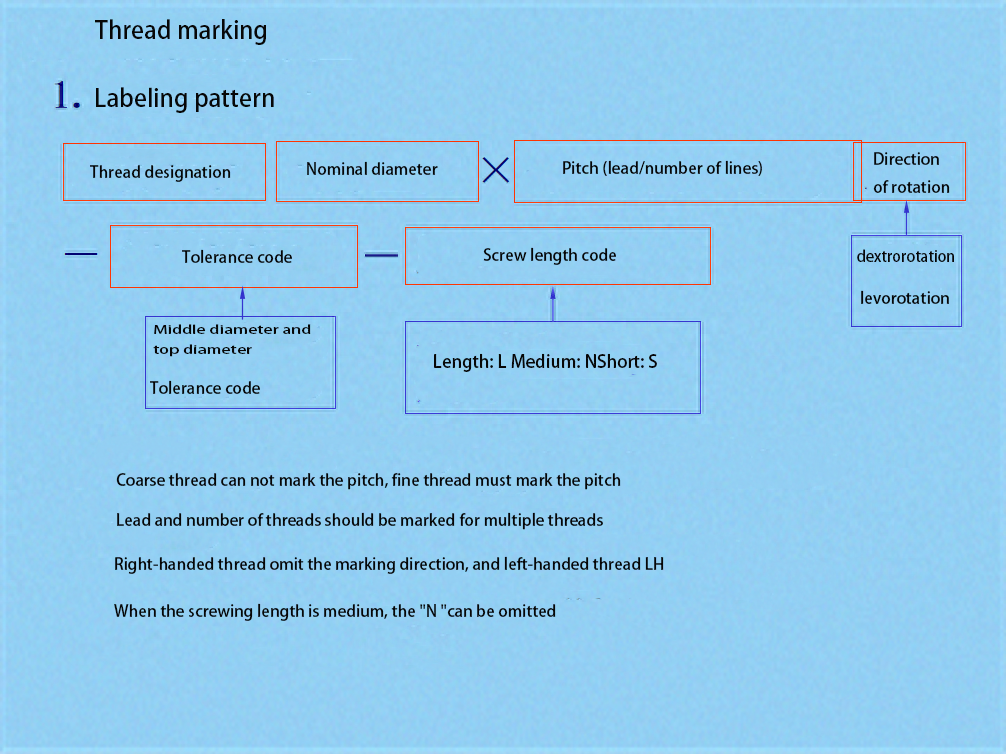

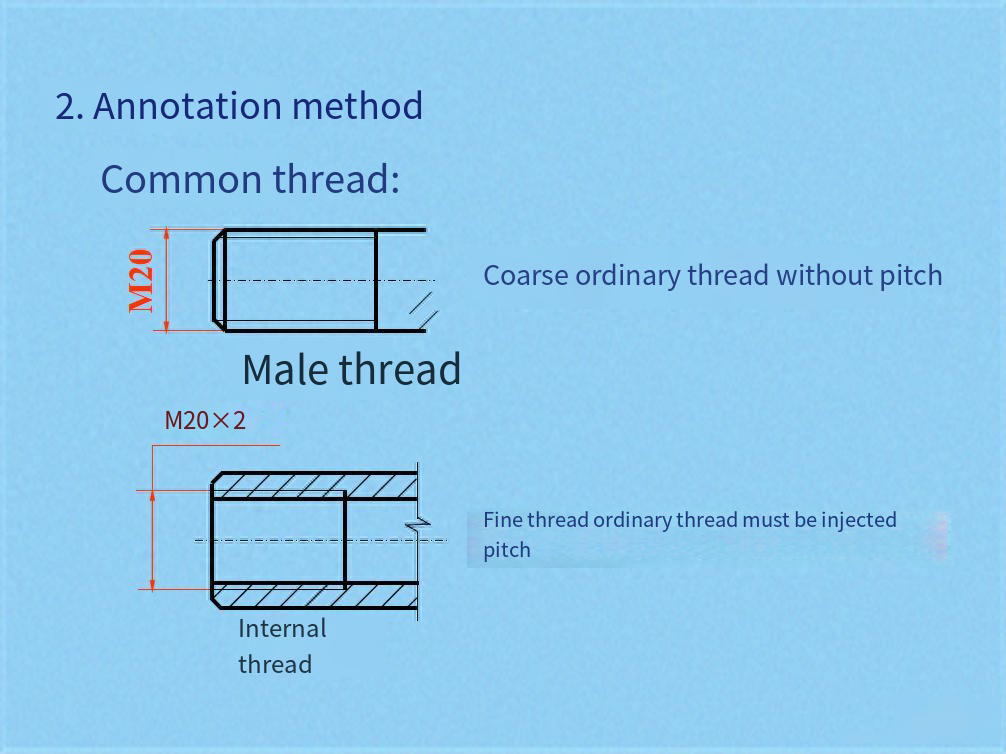

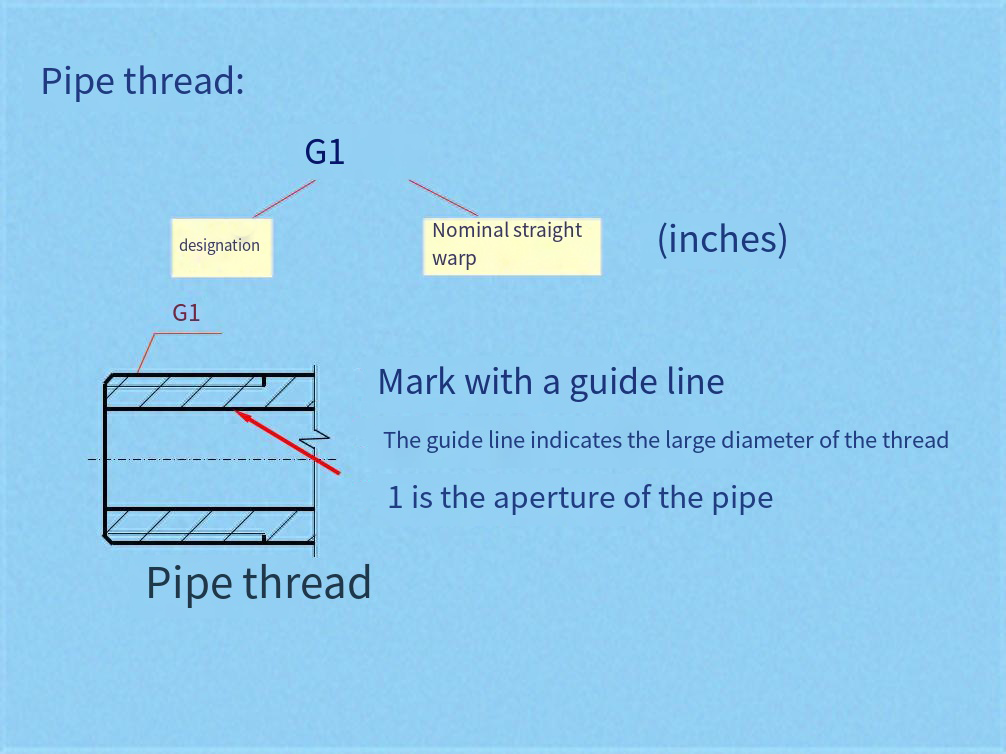

4. Marking of thread

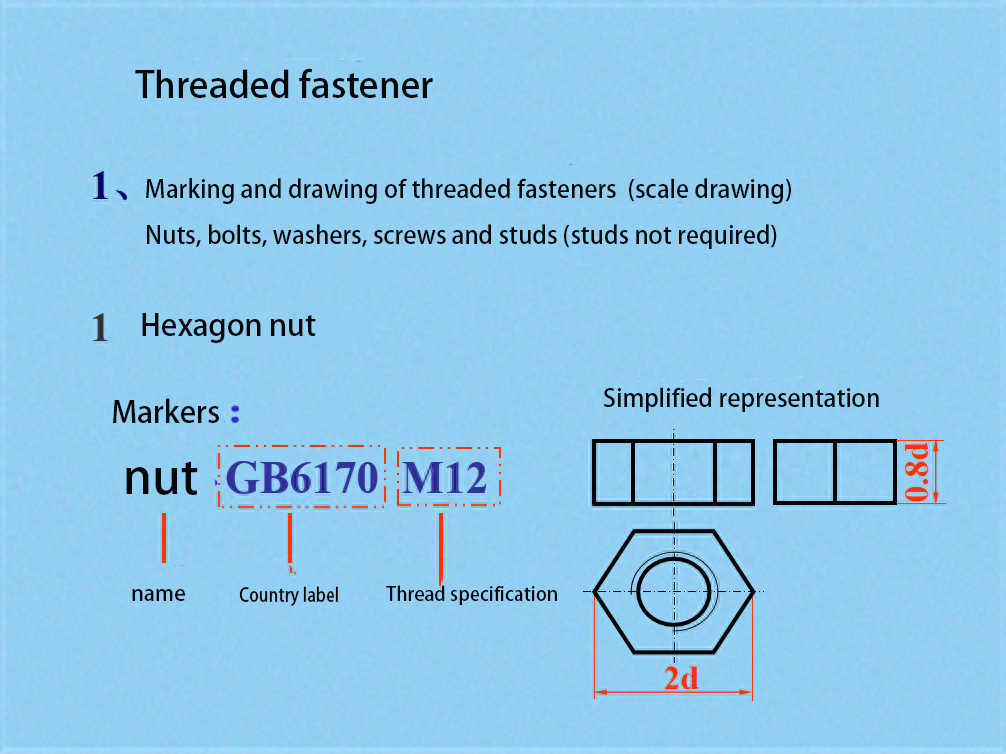

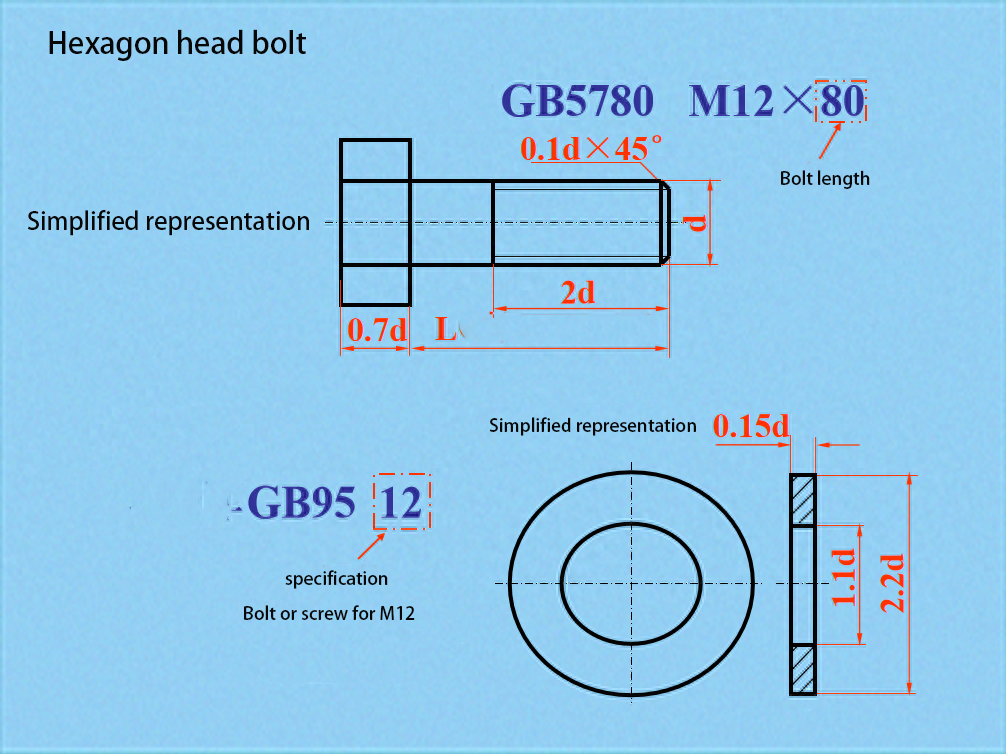

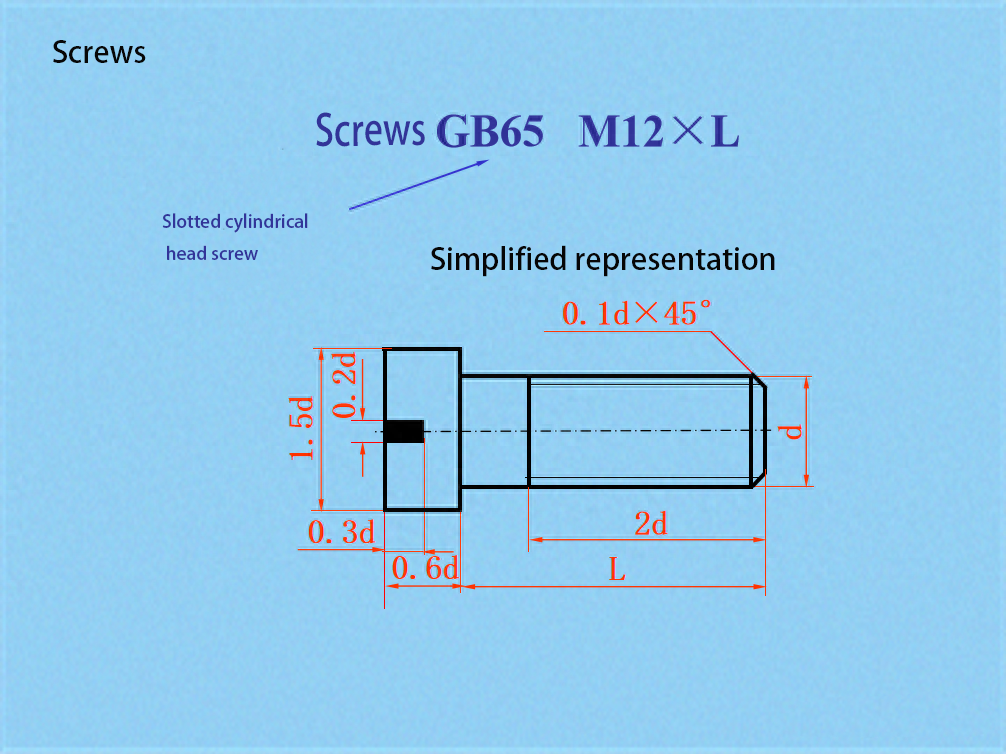

5. threaded fasteners

brief summary

Master thread drawing and marking

Master the drawing of external, internal and threaded connections

Master the marking method of common thread and pipe thread

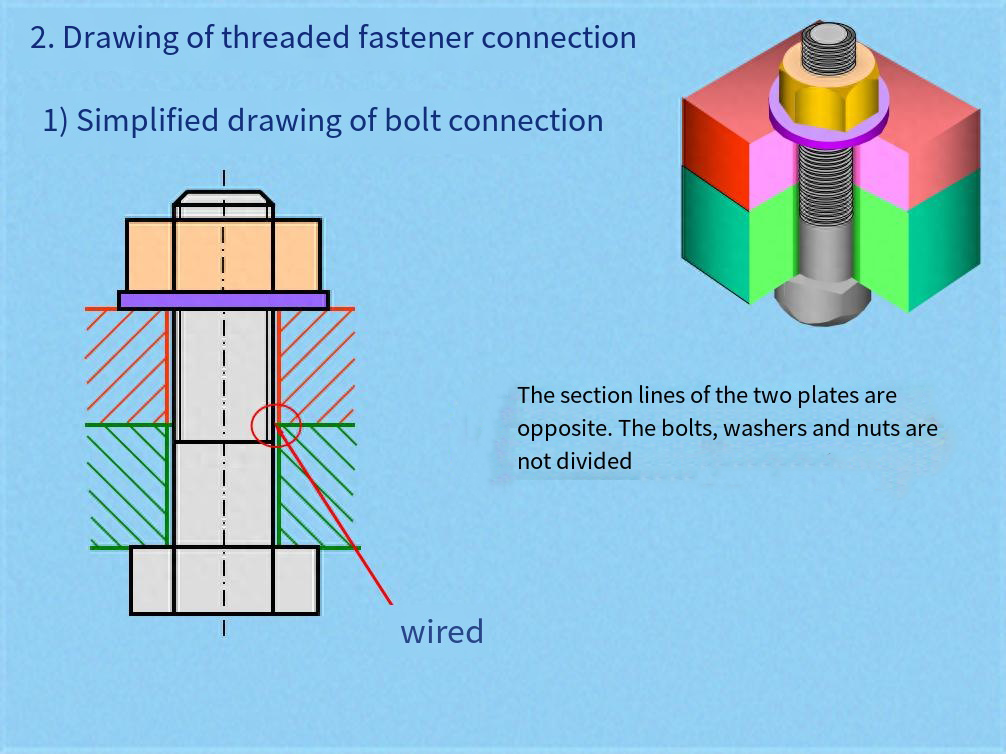

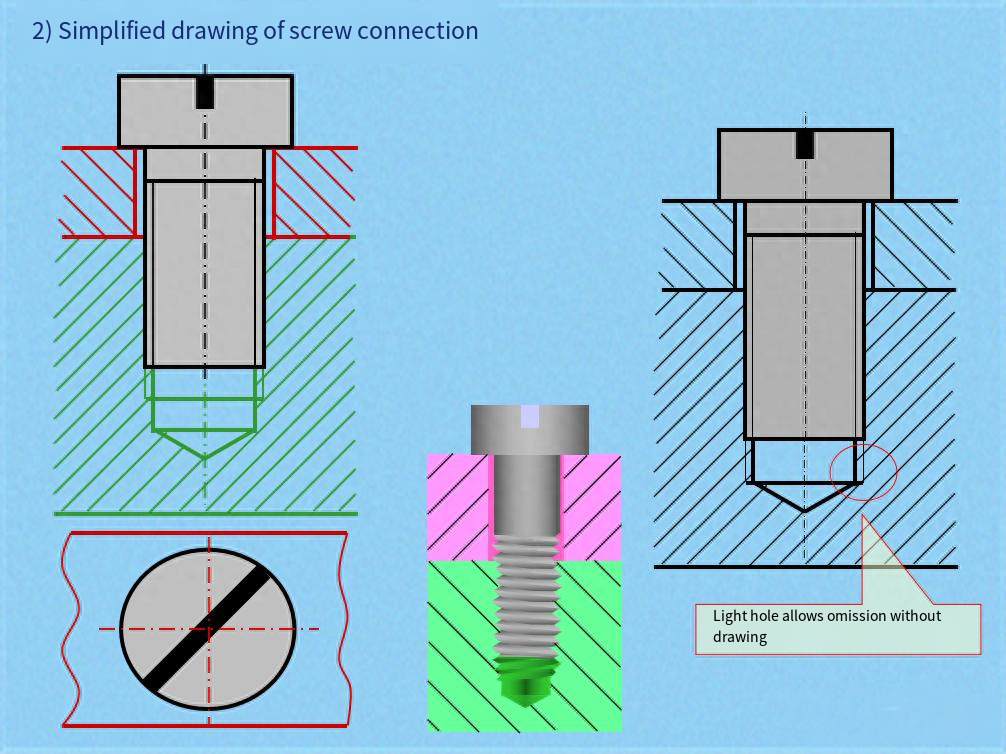

Master the drawing of bolt connection and screw connection

(1) Threads and fasteners

(2) Surface roughness

1. The concept of surface roughness2. Evaluate the parameters of surface roughness3. Surface roughness code and annotation method

Surface roughness refers to the microscopic unevenness on the surface of a part.

2. Evaluate the parameters of surface roughness

Contour arithmetic mean deviation –Ra

Maximum height of profile — Rz

The contour arithmetic mean deviation Ra is preferred

Brief summary

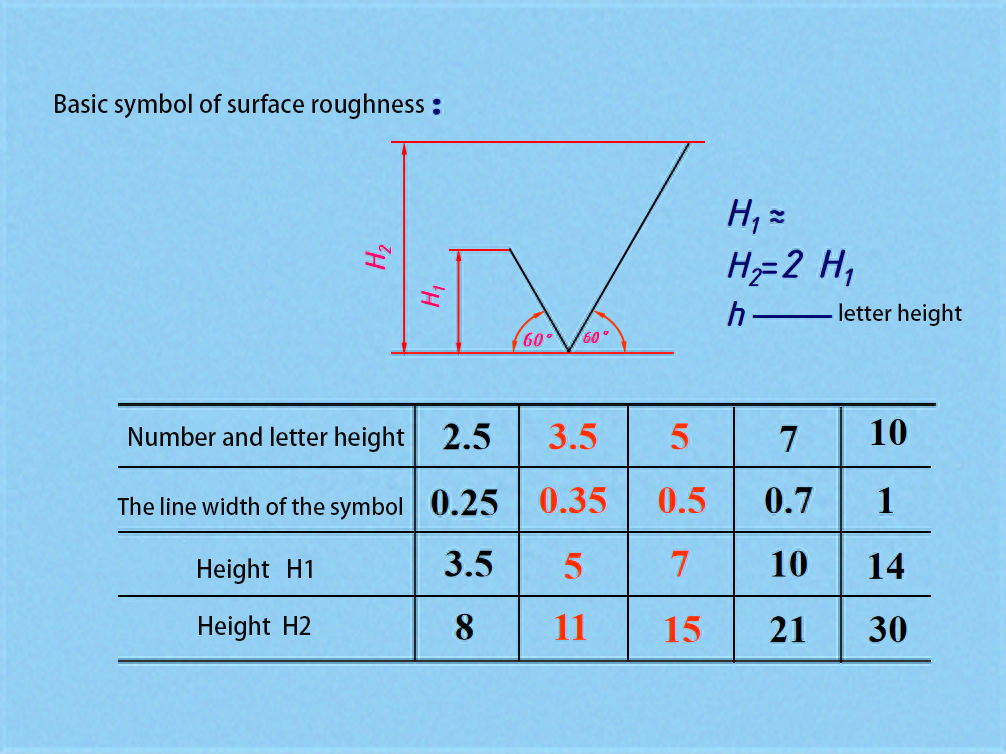

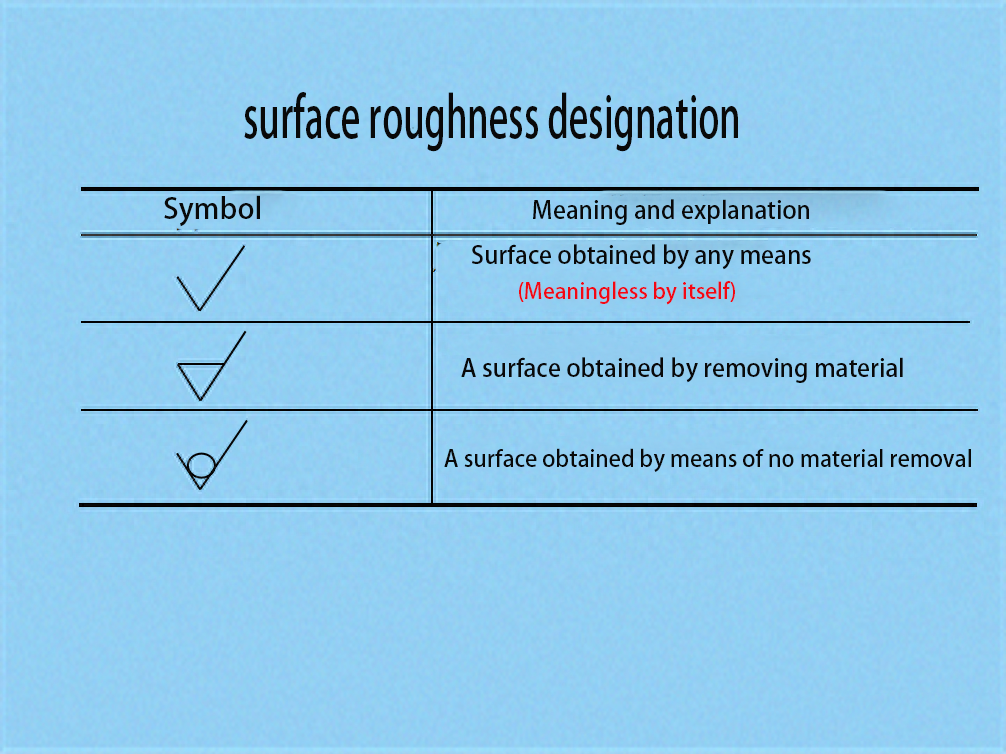

Recognize surface roughness symbols

A representation of the surface roughness of a material that is removed and of a material that is not removed

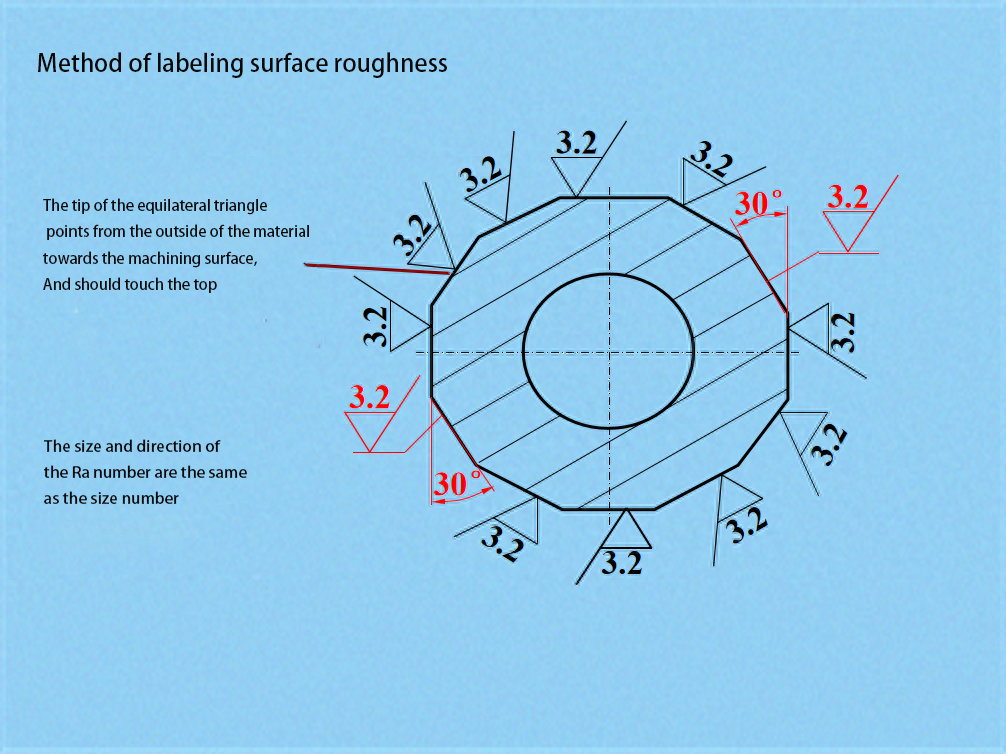

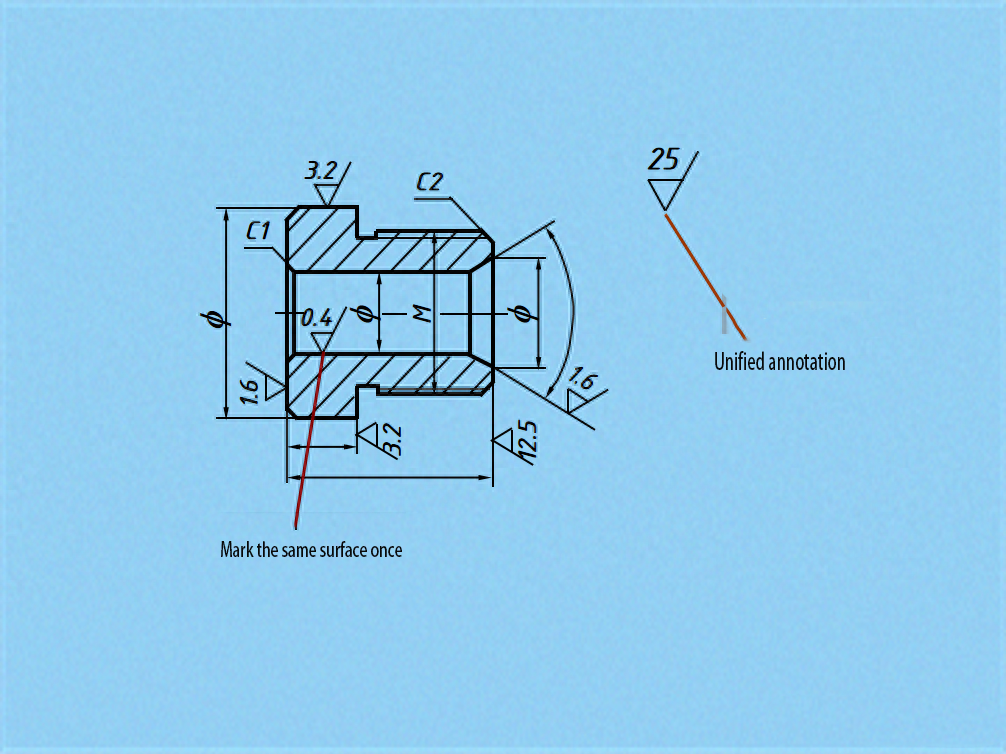

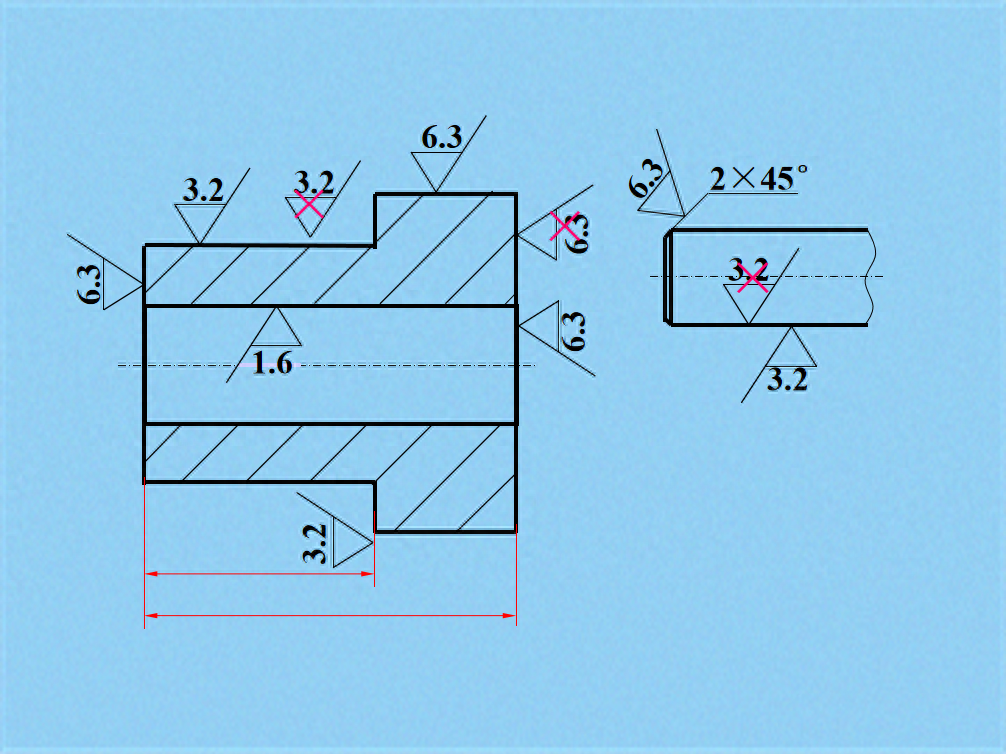

Method of labeling surface roughness

Note the marking requirementsof Ra numbers (prefix direction) and the correct surface roughness symbol

Post time: Sep-27-2023