I. IntroductionIn fact,

in the design process, especially the designers with several years of work experience, under normal circumstances, basically will not consult the manual to determine, such as M10 screws, how big the bottom hole I want to play, how much is the depth, how much tolerance is marked, tapping depth, etc., completely according to the experience value. Of course, in today’s drawing software, the thread depth is generally given, the bottom hole is automatically given, and the standard drawing library has been integrated. However, as the basic knowledge in mechanical engineering, we need to understand its design basis, truly grasp the system in memory, and can flexibly use.

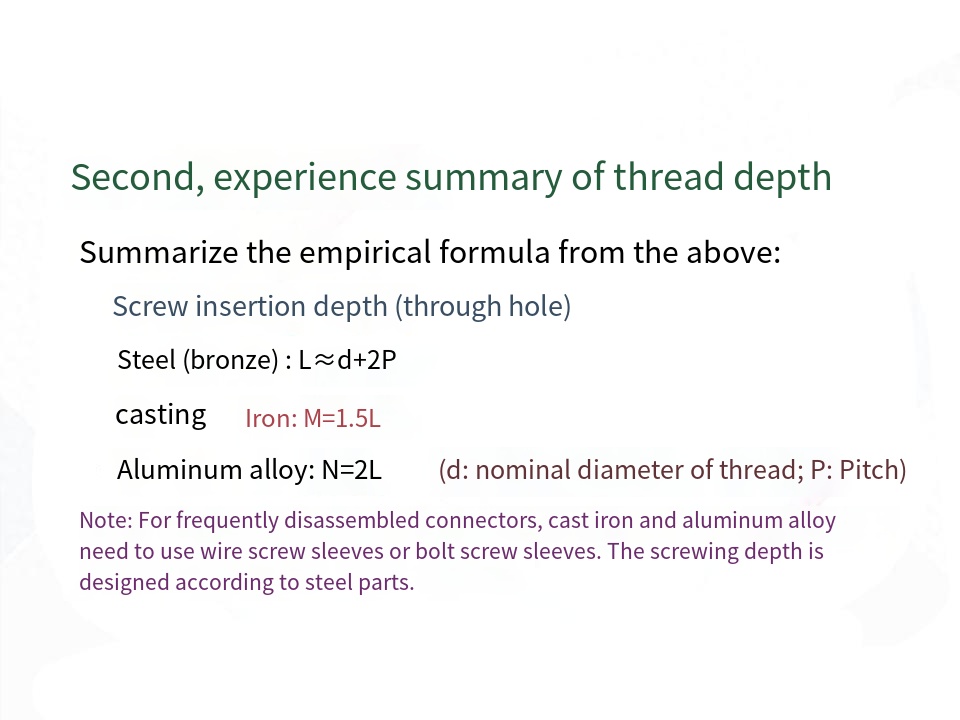

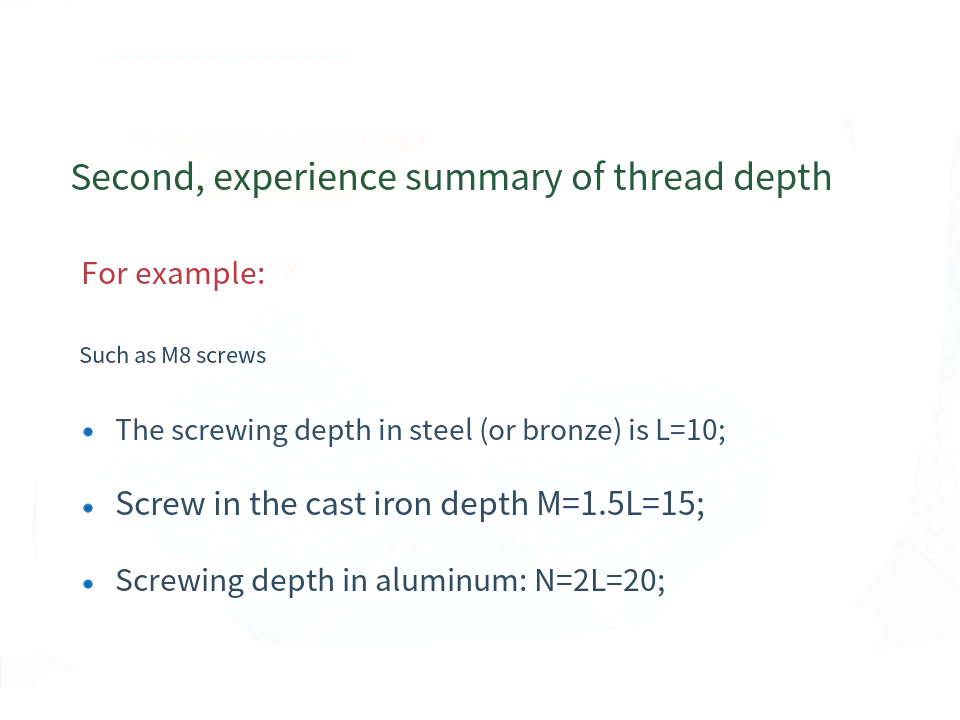

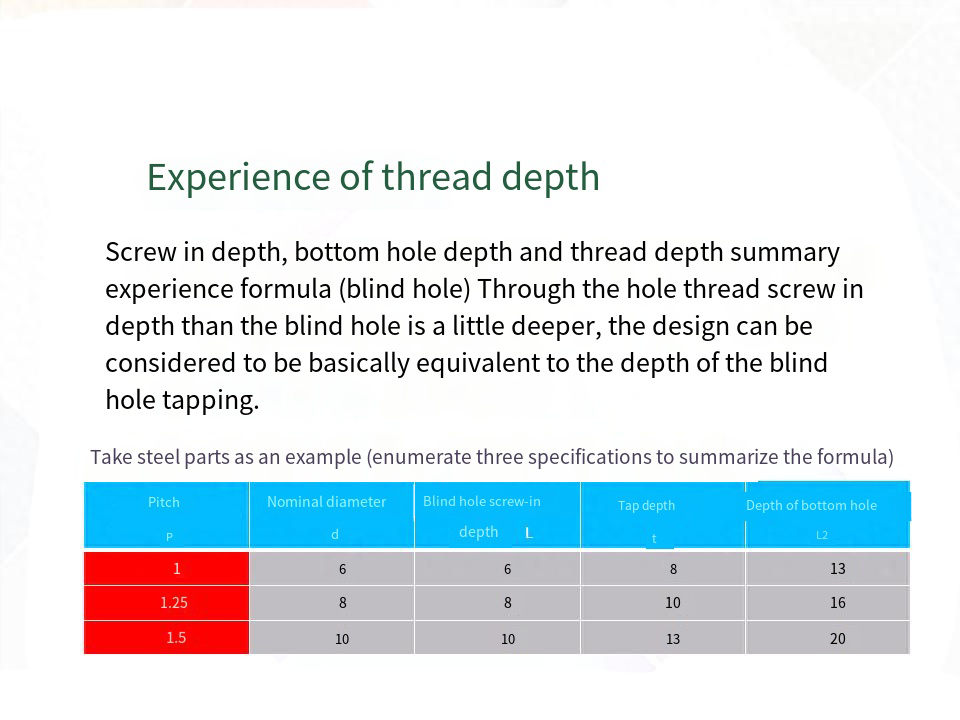

Second, experience summary of thread depth

The following experience is applicable to ordinary coarse tooth connection applications (excluding shear fasteners such as bolts for reaming holes)

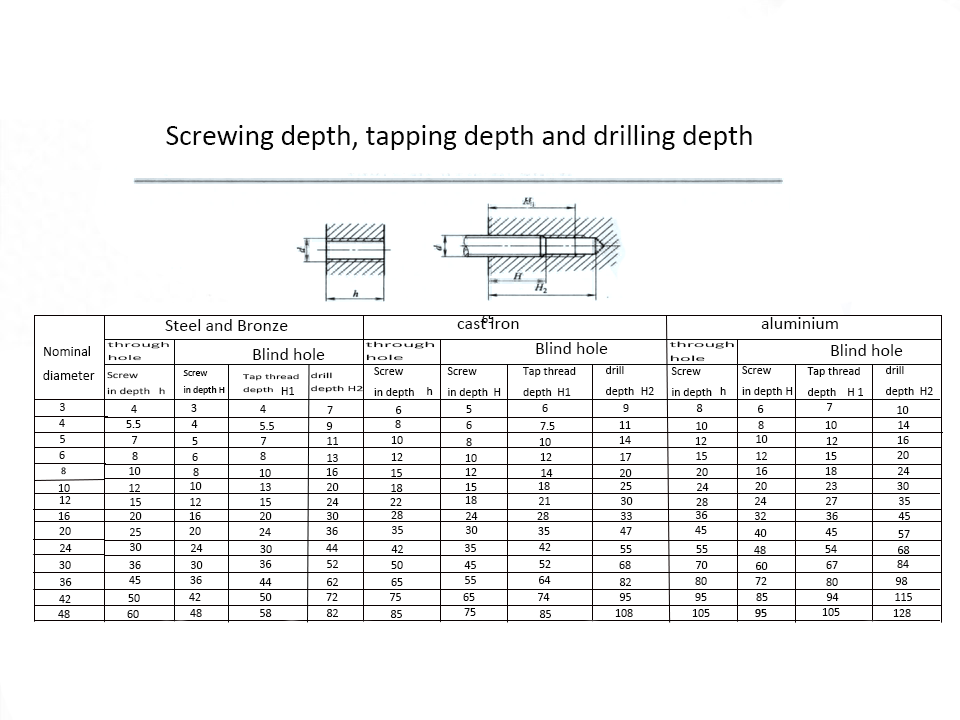

1, the depth of different materials (through holes)It can be seen from the table on the fourth page that the screw insertion depth in different materials is not the same, the same bottom hole depth (blind hole) and thread depth are naturally different, taking through hole M3 as an example, the insertion depth is based on steel (bronze) as the standard in which cast iron is 1.5 times of steel and aluminum is 2 times of steel.

Take the following materials for example:

The tensile strength value of ordinary carbon steel Q235 is 370-500Mpa, and the tensile strength value of gray cast iron HT300 is 300Mpa, and the tensile strength value of aluminum alloy ZL101 (T5 treatment) is 205Mpa. It can be seen that the relationship between the tensile strength value and the screwing depth multiple is similar to the above. (This part of the analysis also applies to blind holes)

The above can be used as the empirical formula of general structure, which can meet the requirements. It should be noted that the table is only a general collection of material types, each can be divided into many kinds of specifications of materials, such as steel is divided into ordinary carbon structural steel, carbon tool steel, rolling bearing steel, etc., cast iron is divided into gray cast iron, ductile cast iron and many other categories, aluminum is divided into pure aluminum, cast aluminum alloy, deformed aluminum alloy, etc., after different heat treatment, each has different tensile strength values. In special cases, they must be treated differently according to the actual requirements of the structure or device.

Post time: Oct-14-2023