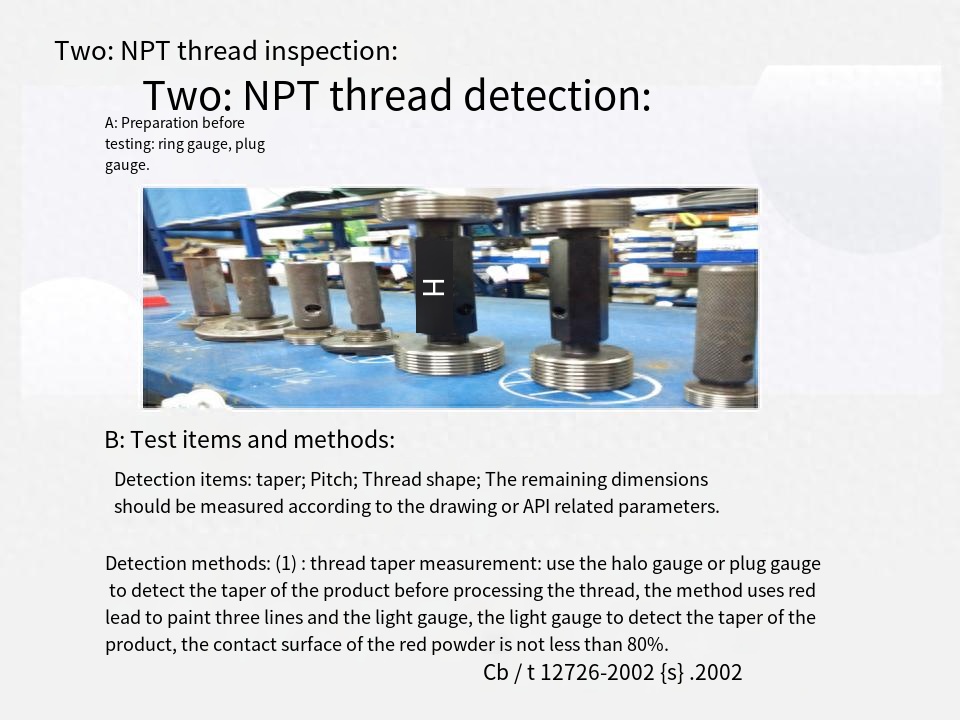

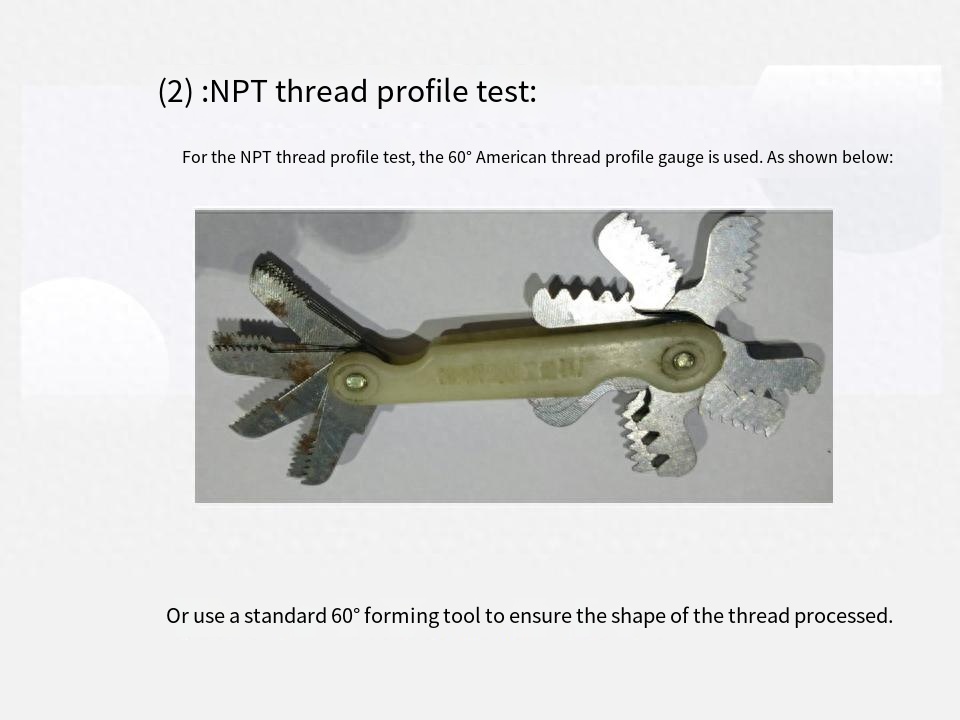

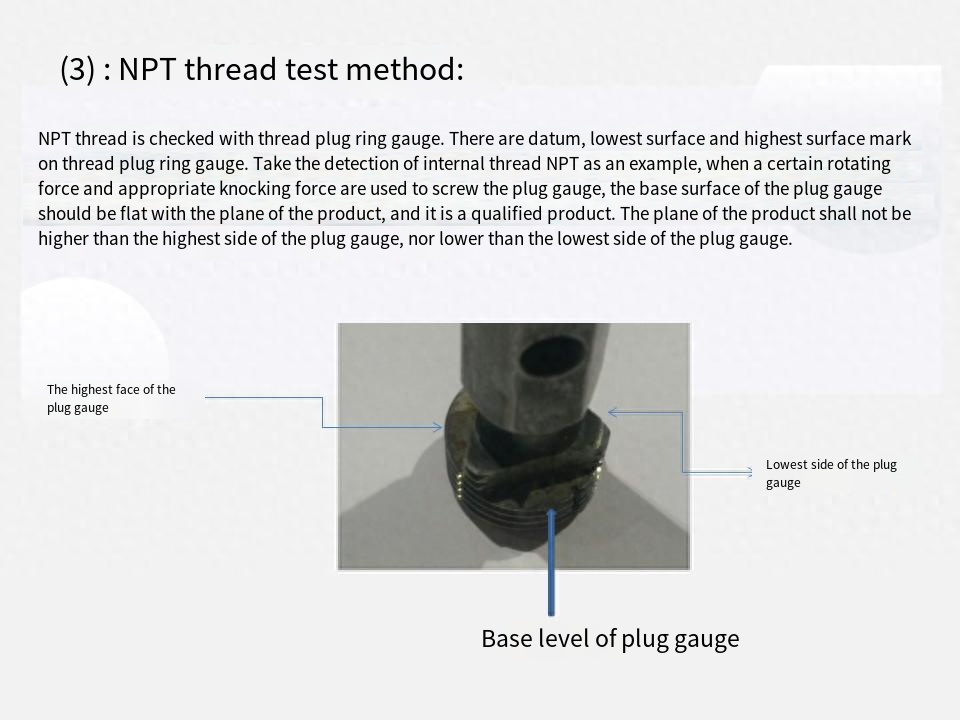

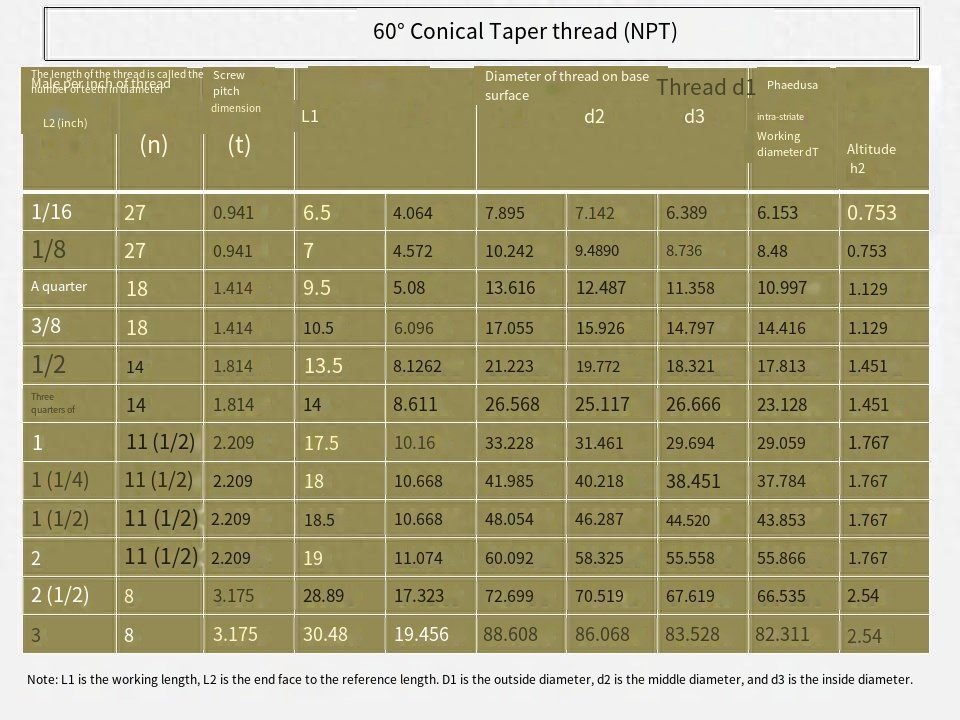

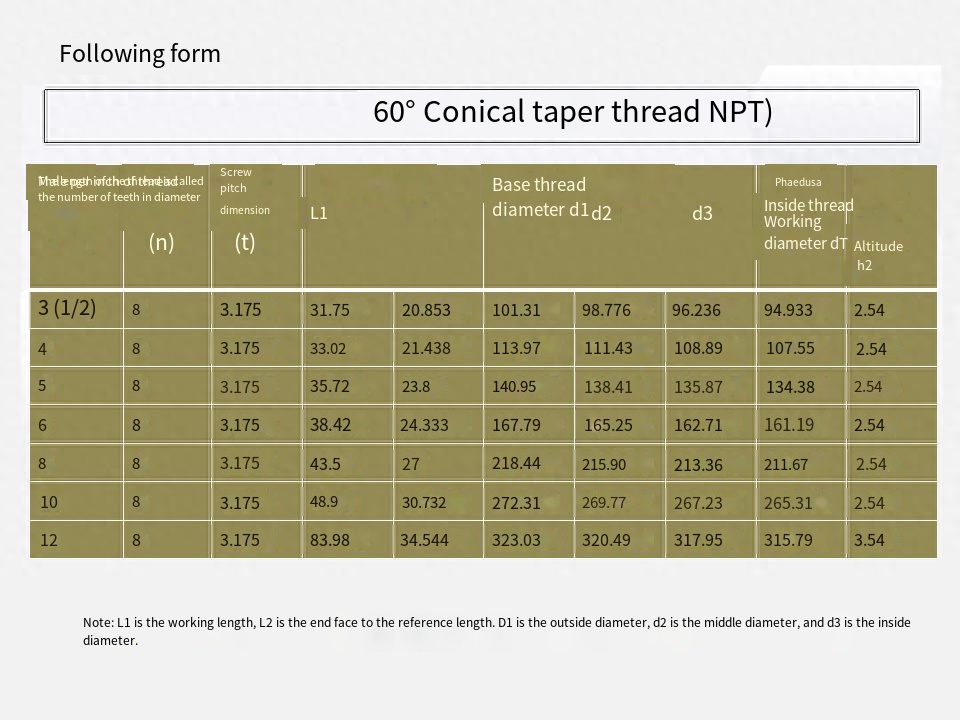

NPT thread is the American standard 60° taper pipe thread. The formula for calculating the warp of the thread is:The formula for the middle diameter of the thread is: D2=d2=D-0.8XPThe formula for thread path is: D1=d1=D-1.6XPThe fit mode of the thread is divided into cone-post fit or cone-cone fit. The length of the thread L is the sum of the actual length of the minimum effective length not less than its reference distance + assembly allowance.After the thread processing, when the finished product is finished, the specification mark of the thread should be marked on the end face of the thread or other eye-catching places, such as: 4-8NPT-LHThe sealing of this thread is completed by the sealing medium between the threads.When there is a dispute over the inspection of the thread plug ring gauge, the professional testing institution shall prevail.

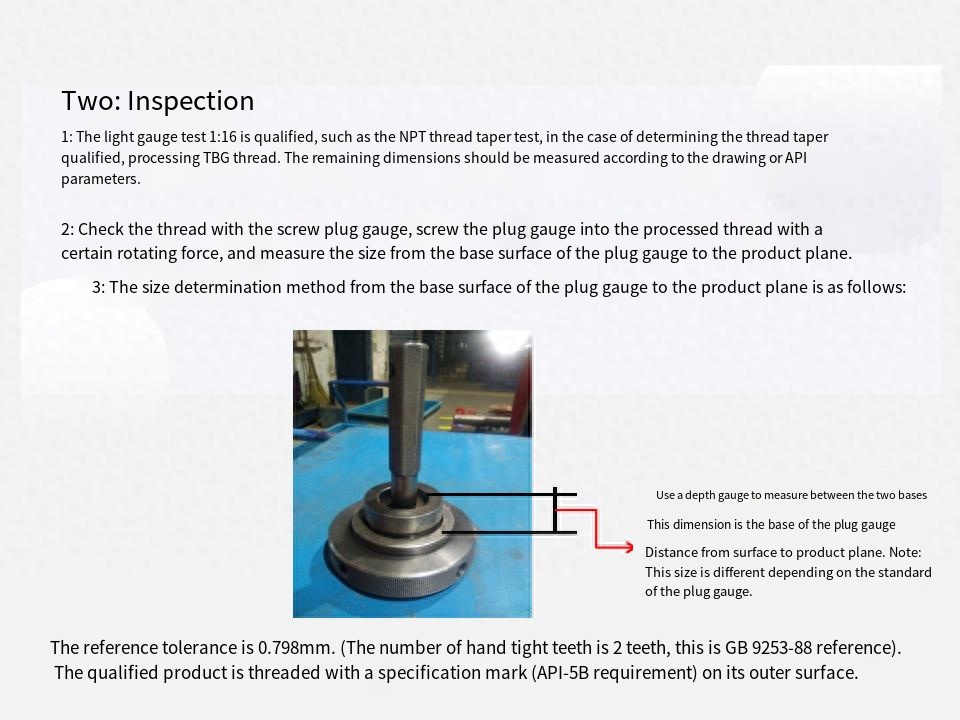

Inspection of TBG thread

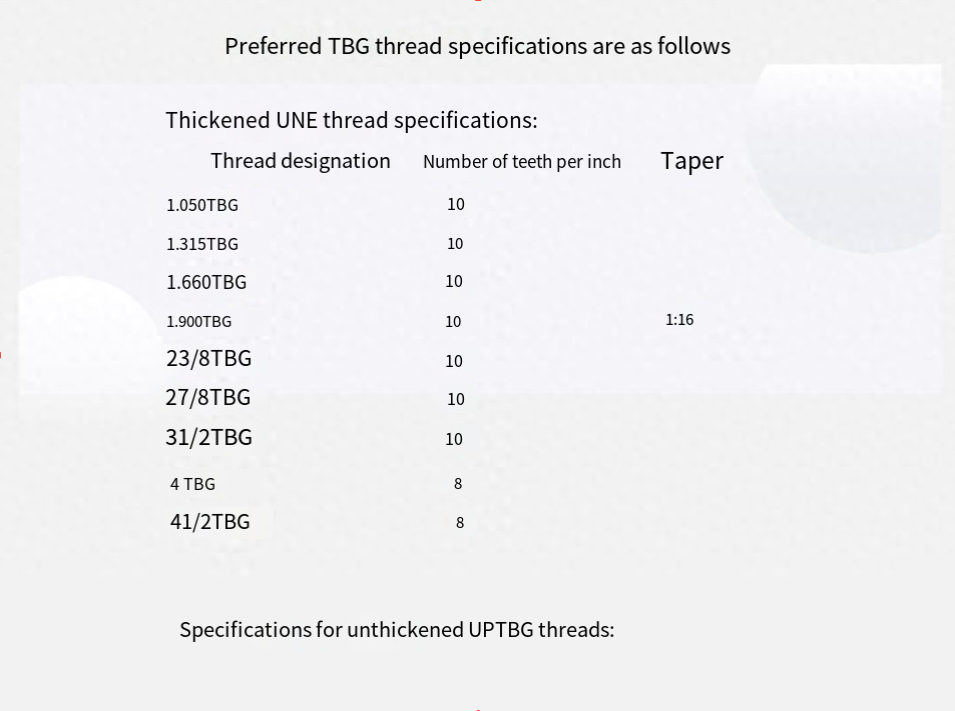

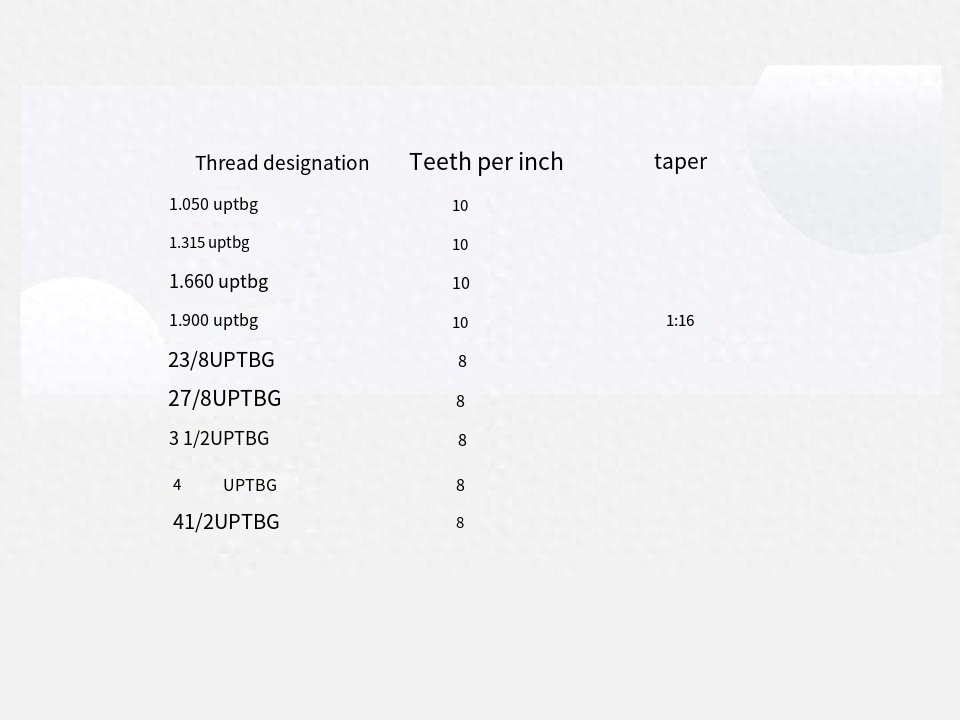

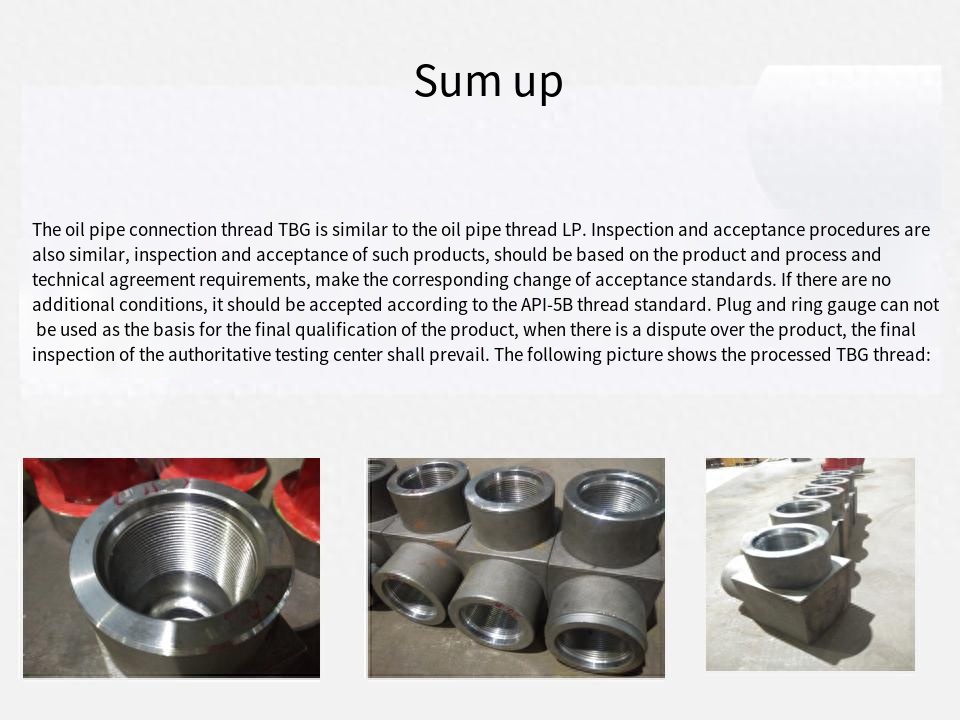

TBG thread is a petroleum pipe connection thread, similar to LP oil pipeline thread, its standard is :API-5B, TBG thread is divided into thick (EUE EU) and not thick (NUE NU) two kinds, the thread Angle is 60° taper is 1:16. The specifications of the unthickened thread are as follows: 1.05TBG; 1.315 TBG; 1.660 TBG; 1.900 TBG; 22/8TBG; 27/8TBG; 31/2TBG; 41/2TBG. UPTBG thickened (EUE)TBG thread, 8 teeth each time, specifications are: 1.05UPTBG 1.05UPTBG; 1.315 UPTBG; 1.660UP TBG;1.900UPTBG;2 2/8UPTBG;27/8UPTBG; 31/2UPTBG; 4UPTBG. 41/2UPTBG

.A: Preparation before inspection: 1:16 light gauge, plug ring gauge. 60° teether gauge.CB/T 12726-2002 (S) .2002

Inspection of American thread:

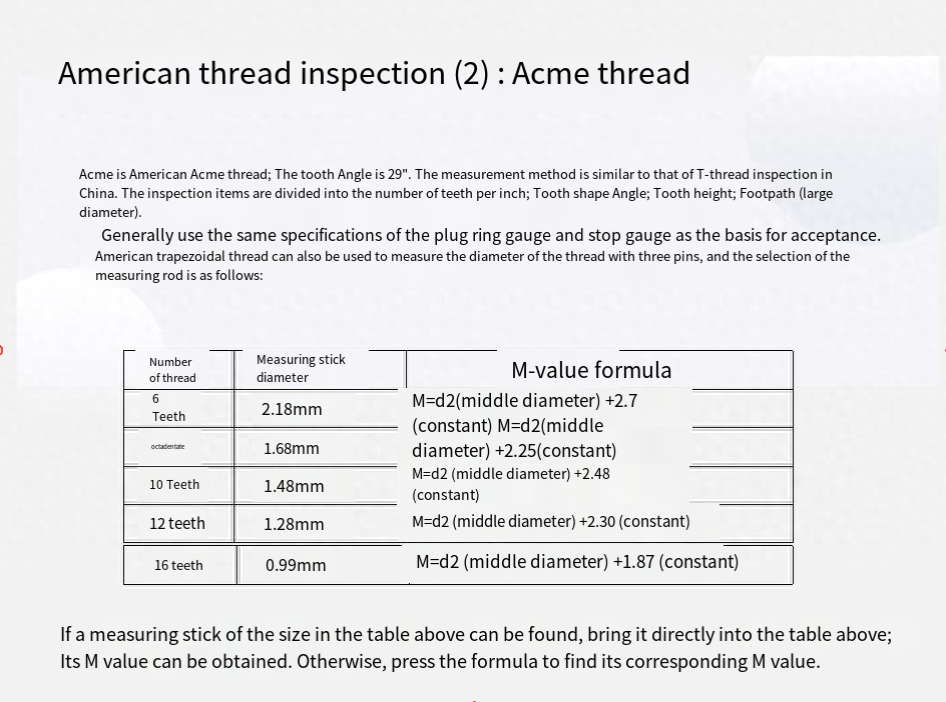

(1)The tooth shape Angle of the American thread is 60°, which is divided into: coarse UNS, fine UNF, ultra-fine UNEF, universal UNC coarse thread. Pitch is expressed in the number of teeth on 25.4mm per inch. Marking methods such as:7/8-9UNC. 2B.The grade of American thread is divided into A and B two kinds, A thread is only applicable to external thread, is divided into 1A; 2A; 3A, the grade of the internal thread is represented by B, also divided into 1B; 2B; 3B. 1A1B has the highest thread grade and is used for U.S. ordnance or other special purposes. 2A2B is suitable for general connection threads and can be coated on the surface of the thread.Inspection method: the large diameter of the United States thread; Small diameter; Medium warp can be converted to metric M values. Then according to the metric M thread inspection method to test the large diameter of the American thread; Small diameter; Middle diameter or with the same specifications of the plug ring comprehensive gauge and stop gauge to check; The rest shall be inspected according to other form and position tolerances and dimensions specified in the drawing process.The method of converting American thread into metric M thread is as follows:Such as: 7/8-9UNC.2B Its nominal diameter is: 22.225mm. Its pitch is: 2.822mm, and its diameter is 22.225(0.6495 x 2.822) = 20.391 mm.Finished American thread product: The product thread identifier must be made on the surface of the product before it can be stored.

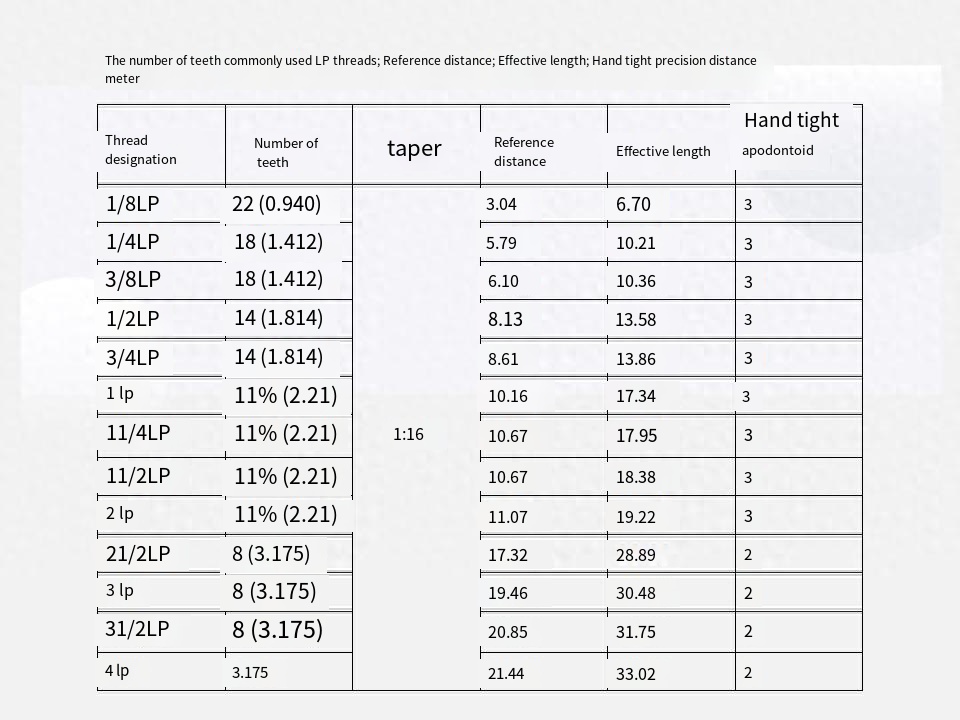

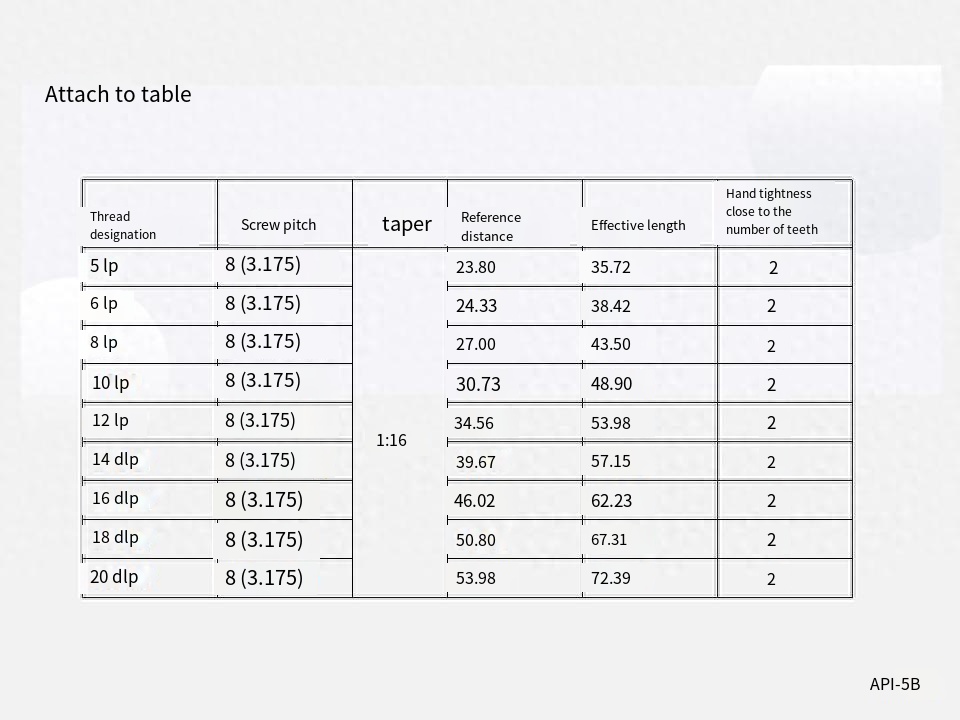

LP oil pipeline thread

inspectionLP oil pipeline thread; Similar to NPT vertebral pipe thread with thread contour Angle of 60° and taper of 1:16. The difference between it and NPT vertebral canal thread is that the height of LP thread of the same specification is lower than that of NPT thread, LP thread height is 0.073P, while the height of NPT thread is 0.033P, that is, the tip of LP thread is much flatter than that of NPT thread. And LP thread has a stop, can effectively protect the thread from damage,LP thread seal is sealed by the tooth line, so the processing accuracy is higher than the NPT thread requirements, and the effective length of the LP thread is longer than the NPT, which increases the processing difficulty.Inspection of LP thread:LP; The inspection of threads is basically similar to that of NPT threads. Need 1:16 light gauge, threaded plug ring gauge. Dental gauge, tooth height ruler, etc. Due to the different specifications of LP threads, the number of hand tight tight distance teeth is also different. This can be checked from the API-5B thread standard. During the inspection and testing, the relevant size acceptance should be carried out according to the drawing process and the size required by the contract. The qualified products should be marked in the eye-catching thread specification.

Post time: Sep-07-2023