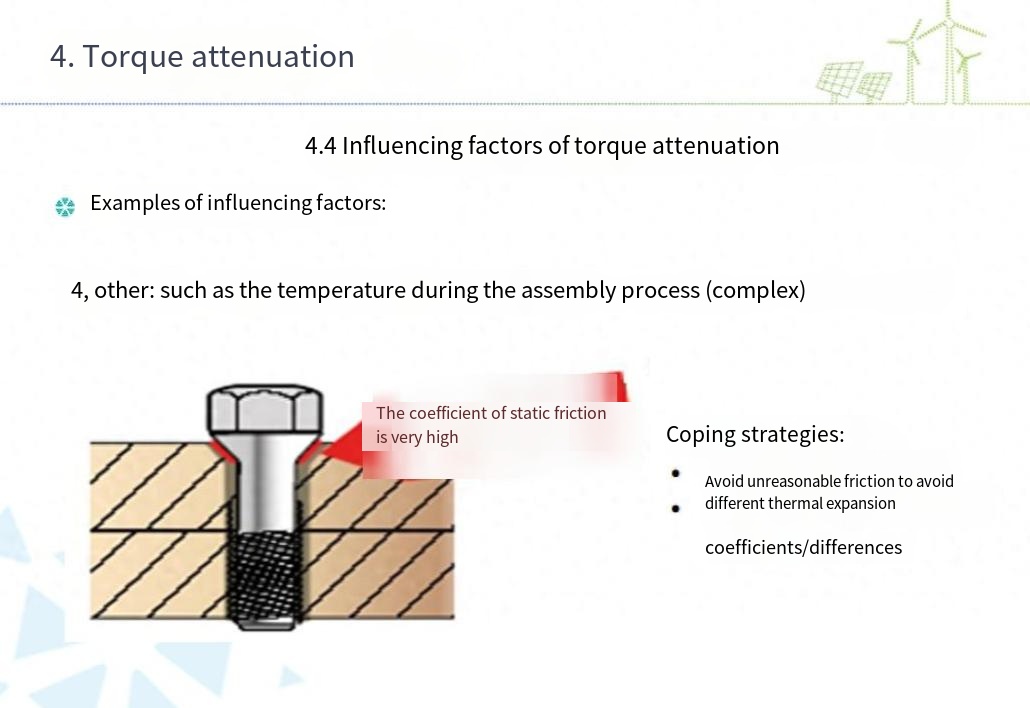

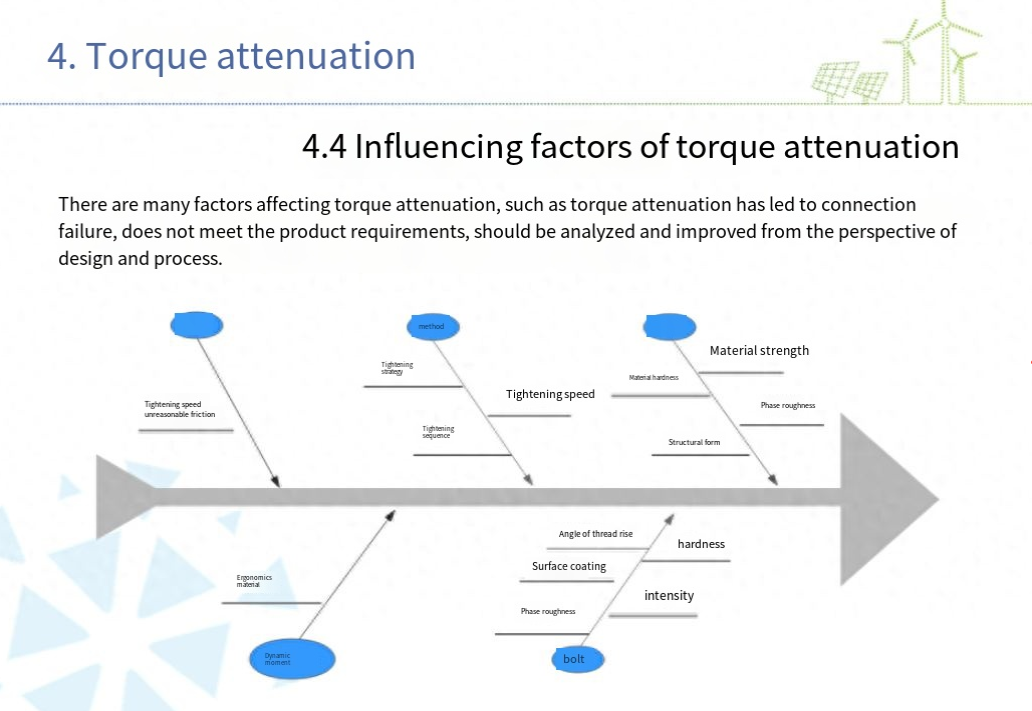

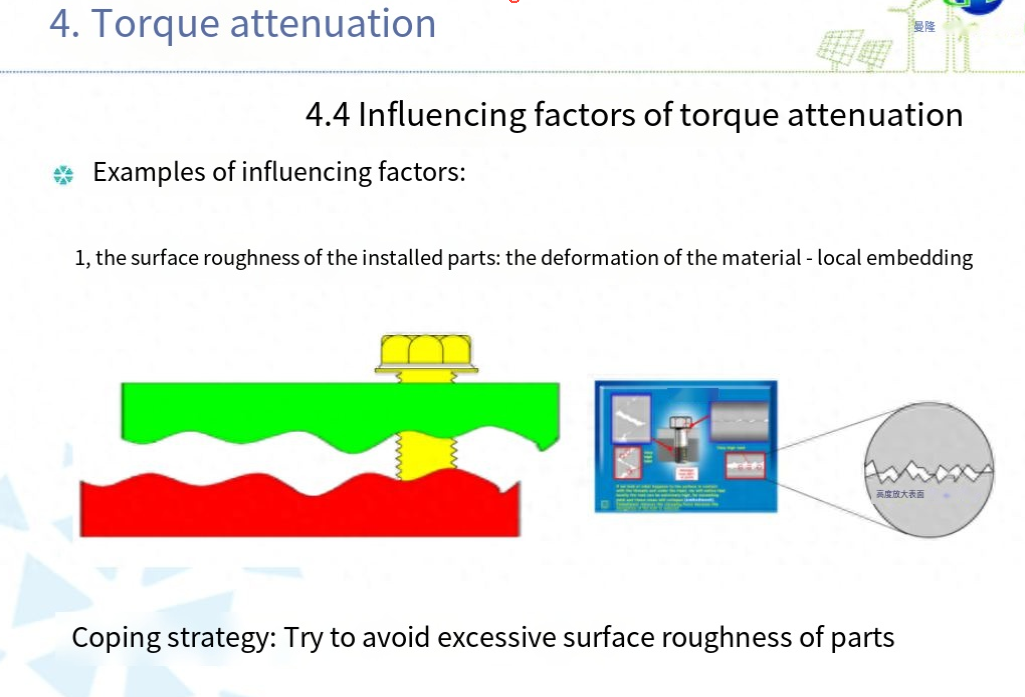

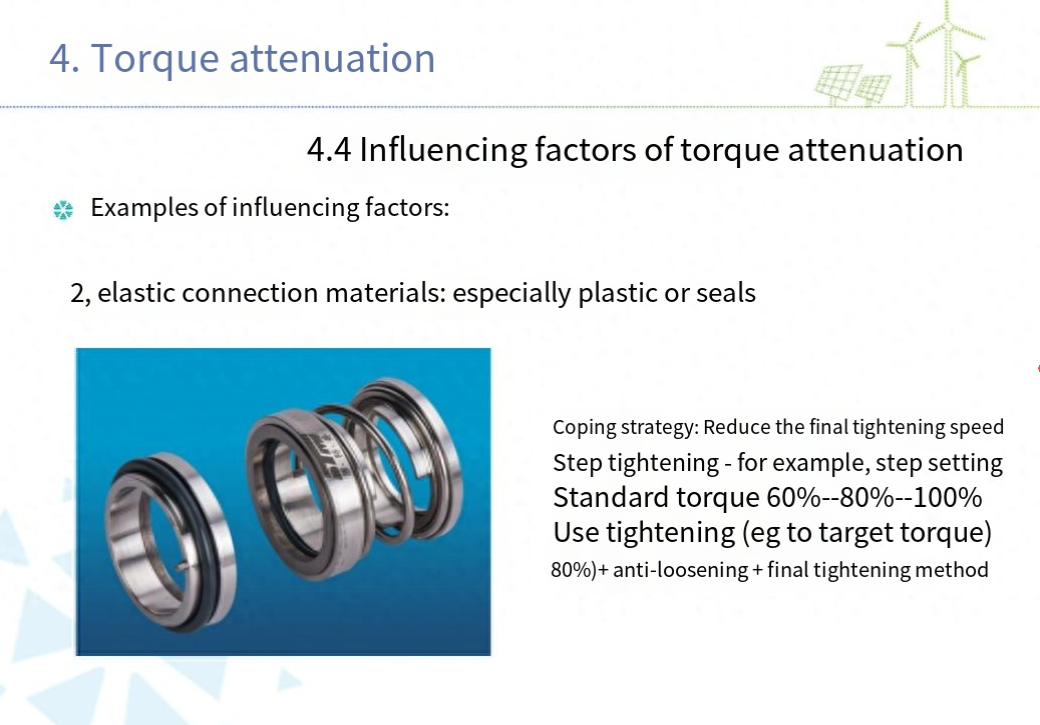

There are many factors affecting torque attenuation, for different forms of torque attenuation improvement measures are not the same, comprehensive above content, from the process and design point of view to consider the common improvement measures of torque attenuation summarized as follows, of course, improvement measures are not limited to the following content.Design Angle:1. Surface roughness: the smaller the surface roughness, the smoother the surface of the material, and the smaller the torque attenuation after tightening.2. Material hardness: Improve the hardness of the material, the more difficult the material surface is embedded between each other, the smaller the torque attenuation.3. Elastic materials: plastic or rubber, etc. should be used as little as possible. If necessary, a comprehensive tightening strategy should be formulated to ensure that the clamping force after attenuation meets the product requirements.4, bolt selection: fine teeth bolt compared with coarse teeth bolt pitch is smaller, screw Angle is also small, in use is not easy to loose, so the use of fine teeth bolt torque attenuation will be lower than coarse teeth

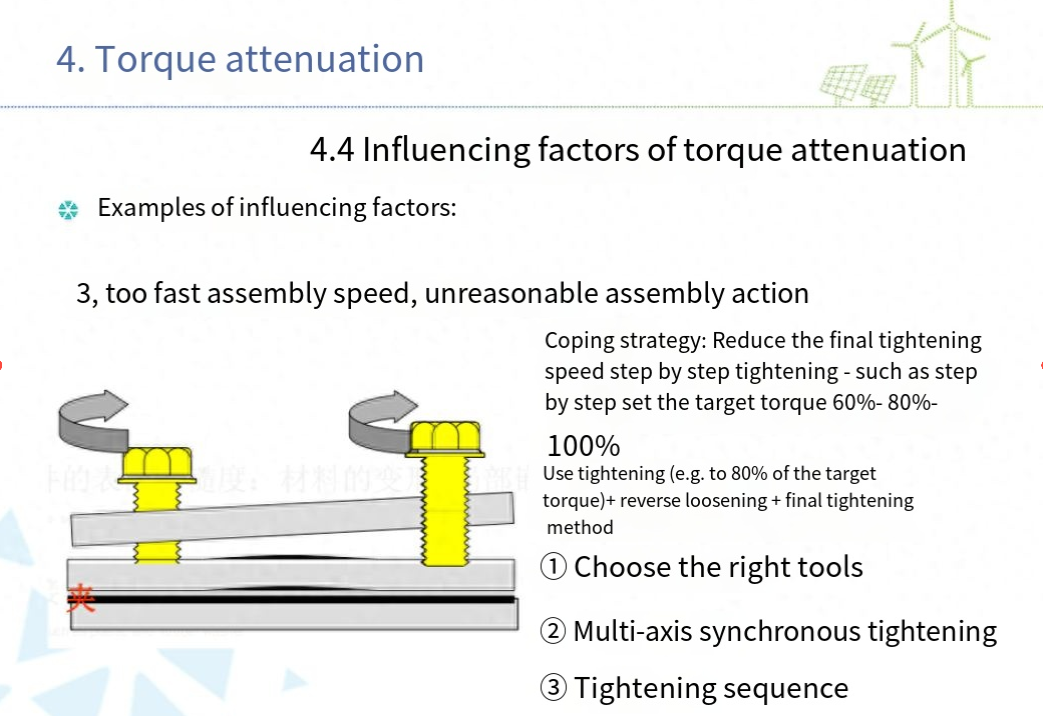

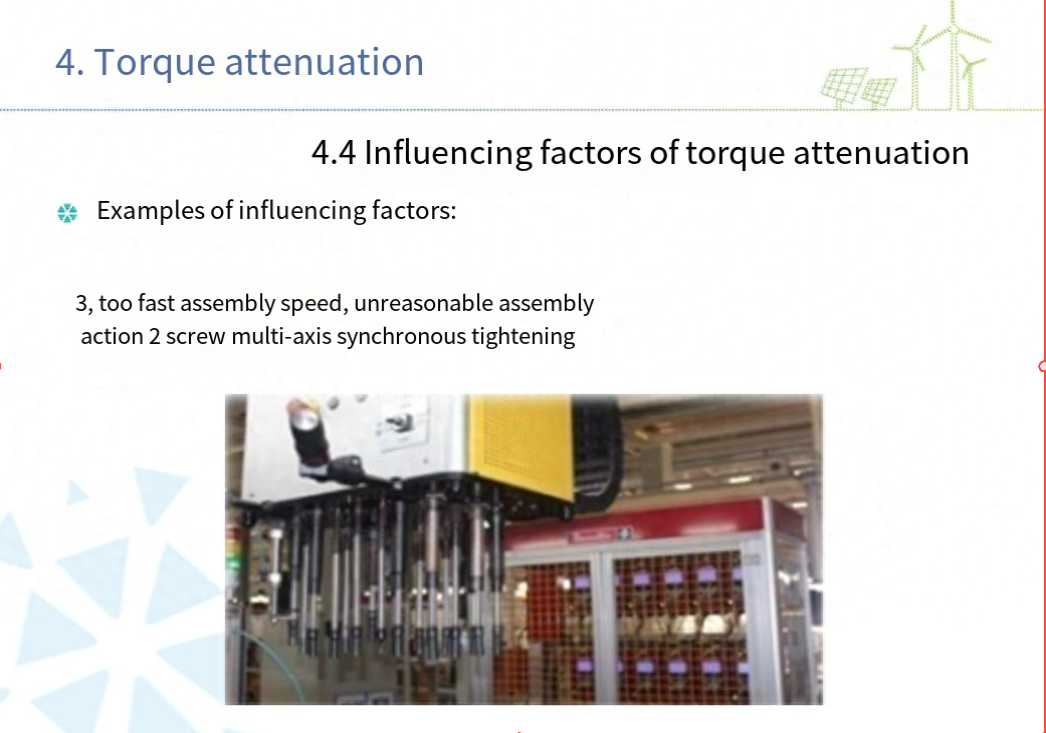

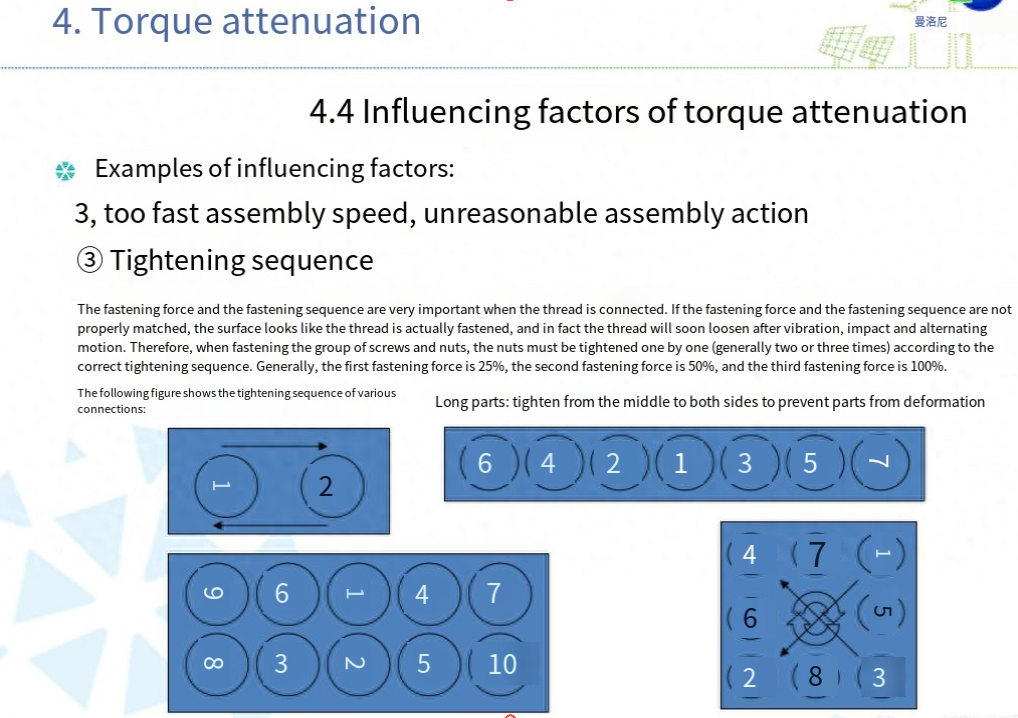

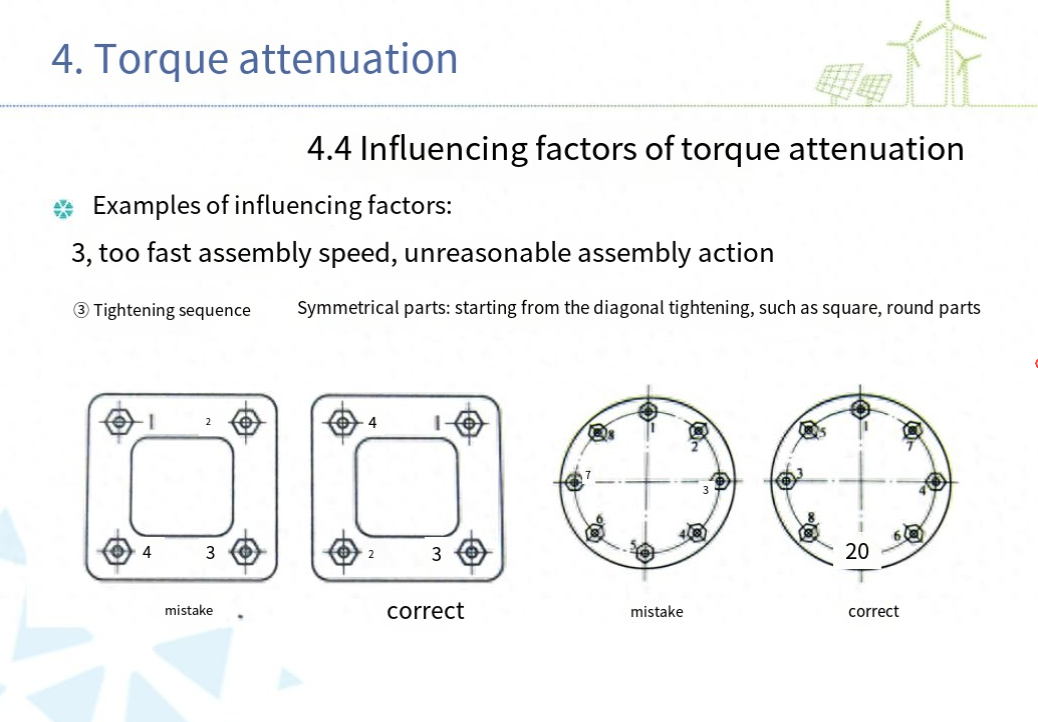

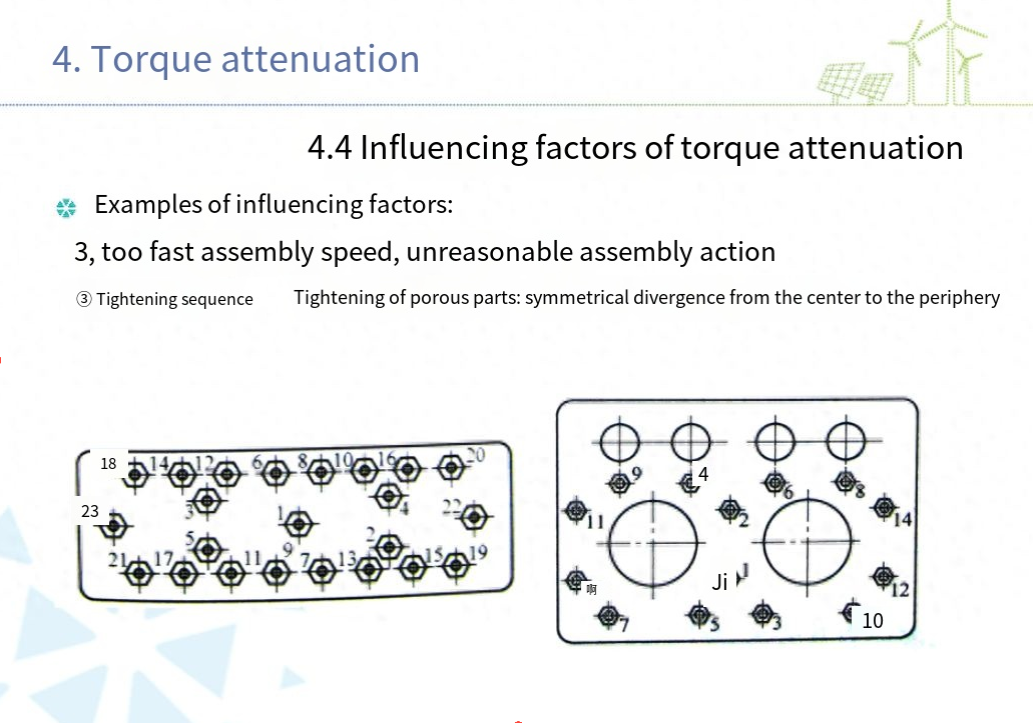

Process Angle:1. Tightening strategy: Change the tightening strategy, two-step tightening or multi-step tightening, and pause 50ms in the tightening process to release elastic strain and reduce attenuation.2. Tightening speed: When the workpiece is pressed, the burr departs under the larger clamping force, the “shorter” clamping force decreases, the residual torque synchronically decreases the faster the tightening speed, the smaller the initial deformation of the burr, the more the residual torque decreases, therefore, reducing the tightening speed can reduce the torque attenuation.3. Tightening sequence: Change the single-axis tightening to several axes tightening at the same time, which can reduce torque attenuation: or take a single-axis multi-step gradual tightening to the target torque, which can also reduce torque attenuation.

Post time: Sep-04-2023