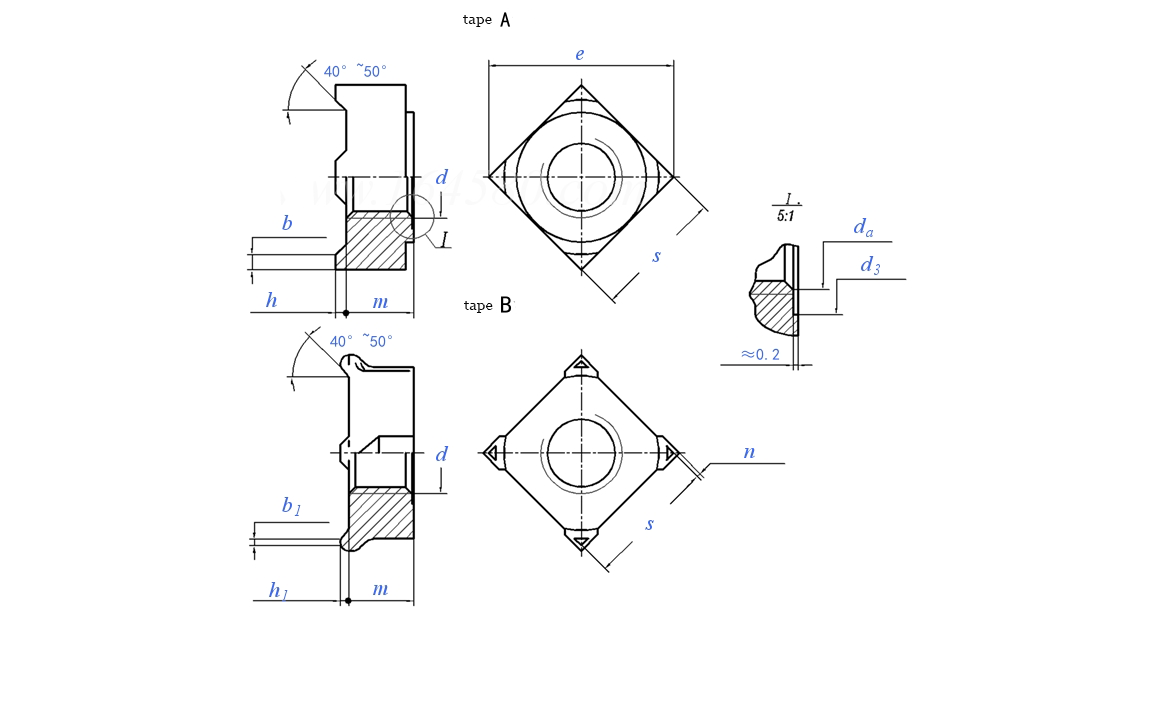

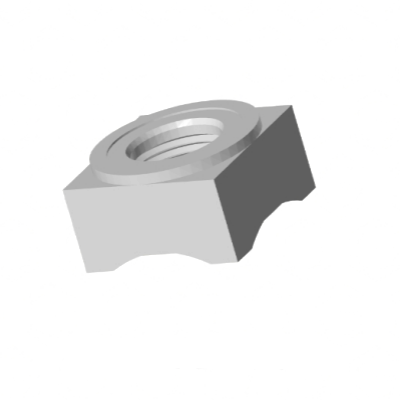

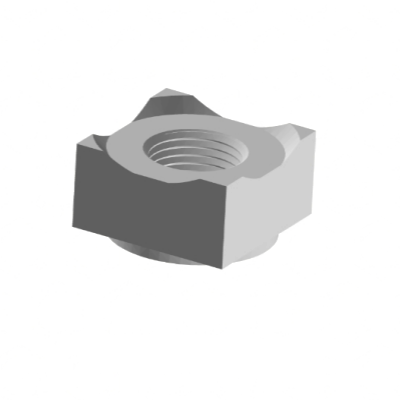

The most common types of welded nuts are hexagonal welded nuts and square welded nuts. Among them, square welded nuts are widely used in fields such as power engineering, road traffic, furniture and building materials. However, when using square welded nuts, improper operation can lead to problems such as welding pores and large deformation, which affect the connection effect.

This requires attention to the following details when using square welded nuts:

(1) The square welding nut is suitable for welding thin plates below 6mm, which reduces welding deformation and makes the weld formation more beautiful. If the welded thin plate is too thick, it is prone to significant deformation;

(2) When welding, direct current should be used, and the negative electrode should be connected to one end of the welding to avoid defects such as welding pores and cracks;

(3) When welding square nuts, there are strict requirements for protective gas and other parameters. The protective gas is argon gas with a purity of 99.9%. When the welding current is between 50-150A, the argon gas flow rate should reach 8-10L/min. When the welding current is between 150-250A, the argon gas flow rate should be 12-15L/min;

(4) At the same time, in order to better protect the welding pool with argon gas and facilitate welding operations, the center line of the tungsten electrode and the welded workpiece usually need to maintain an angle of 80-85 °, and the angle between the filling welding wire and the surface of the workpiece should also be as small as possible, usually around 10 °;

(5) Before welding the square welded nut, in order to avoid welding pores, the oil stains, rust, and other dirt on the welding area should be removed thoroughly;

(6) To ensure safety during welding construction, mesh blocking measures should be taken in windy areas, and appropriate ventilation measures should be taken for indoor welding.

The above are the details that need to be paid attention to when welding square nuts. Everyone must pay attention to them during construction.